Description

Detailed Parameter Table

| Parameter name | Parameter value |

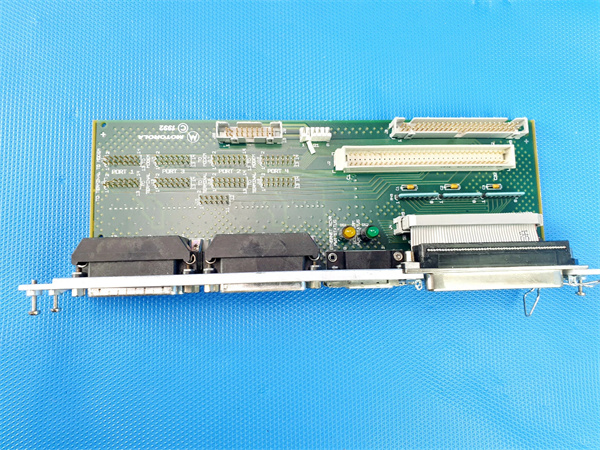

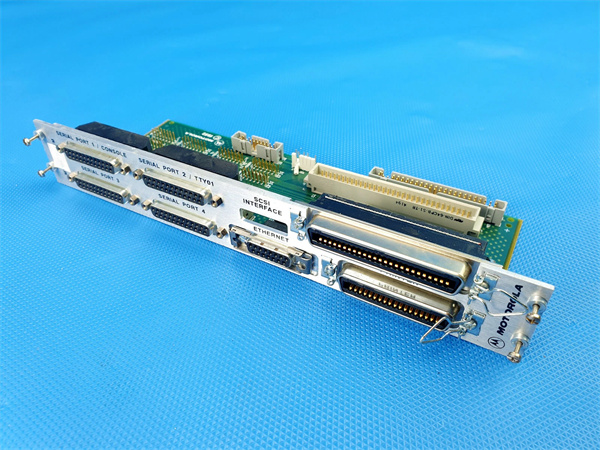

| Product model | MVME-712/M |

| Manufacturer | Motorola (now integrated into Emerson’s industrial automation product portfolio) |

| Product category | Industrial Digital Output Module (VMEbus-compatible, discrete control signal output) |

| Digital Output Channels | 16 isolated digital output channels (grouped into 2 banks of 8 channels each) |

| Output Signal Type | Sourcing output (PNP); supports both dry contact (switching external loads) and wet contact (direct voltage output) |

| Output Voltage Range | 10-30 VDC (continuous output); 5 VDC TTL-level output (configurable via on-board DIP switches) |

| Output Current Capacity | 1 A per channel (continuous); 3 A per channel (peak, 100 ms duration); 8 A per channel bank (total current limit) |

| Isolation Level | 2.5 kVrms galvanic isolation between output channels and VMEbus backplane; 1 kVrms isolation between channel banks |

| Bus Compatibility | Complies with VMEbus IEEE 1014-1987 standard (3U form factor); supports VMEbus A16/D16 address cycles and interrupt requests (IRQ 2-6) |

| Environmental Requirements | Operating temperature: -10°C to 65°C (14°F to 149°F); Storage temperature: -40°C to 85°C (-40°F to 185°F); Relative humidity: 5% to 95% (non-condensing); Vibration resistance: 5-500 Hz, 1.5 g (peak); Shock resistance: 50 g (peak, 10 ms duration) |

| Physical Size | 3U VMEbus form factor (100 mm x 160.02 mm / 3.94 in x 6.30 in); weight: 170 g (0.37 lbs) |

| Installation Method | VMEbus backplane mounting; compatible with 3U/6U VME chassis; requires VMEbus standard power supply (+5V, +12V, +24V optional for high-load operation) |

| Protection Features | Overcurrent protection (1.2 A per channel, self-resetting); short-circuit protection (all channels, latching until fault clearance); ESD protection (±15 kV contact, ±8 kV air) on output terminals; over-temperature protection (85°C, auto-recovery) |

| Diagnostic Features | Built-in self-test (BIST) function; LED indicators for module power, channel-level output status (16 LEDs, 1 per channel), BIST results, and overcurrent/short-circuit faults |

| Power Consumption | Typical: 5 W (at 25°C, 24 VDC output, 50% channel load); Maximum: 12 W (full channel load, 24 VDC) |

| Compatibility | Optimized for MVME series single-board computers (e.g., MVME-147-023, MVME-162-001); works with MVME digital input modules (MVME-717, MVME-121) and power modules (MVME-050) |

| Response Time | ≤2 ms (from digital command to output signal activation); ≤1 ms (output signal deactivation) |

Motorola MVME-712/M

Product Introduction

The Motorola MVME-712/M is a reliable industrial digital output module developed by Motorola—a pioneer in legacy industrial automation hardware—and now part of Emerson’s trusted product ecosystem. As a key discrete control component in the MVME series, it is engineered to convert digital control commands from VMEbus-based controllers into isolated, high-current output signals for industrial actuators, enabling precise control of devices like solenoid valves, relay coils, and indicator lights.

Designed to complement the input capabilities of modules like the Motorola MVME-717, the Motorola MVME-712/M features 16 isolated output channels, flexible voltage support, and robust load protection—making it ideal for closed-loop control systems. In automation architectures, the Motorola MVME-712/M acts as a “control executor”: it receives digital commands from MVME series single-board computers (such as the MVME-147-023) that process input data from the MVME-717, then sends output signals to actuate field devices. For example, in a conveyor system, after the MVME-717 detects a jammed part via limit switches, the MVME-147-023 sends a “stop” command to the Motorola MVME-712/M, which activates a conveyor brake solenoid. Its galvanic isolation ensures output signals are not affected by electrical interference from nearby motors, making it a staple in manufacturing, material handling, and automotive assembly.

Core Advantages and Technical Highlights

Balanced Channel Density with High Load Capacity: The Motorola MVME-712/M offers 16 output channels in a compact 3U form factor—striking a balance between space efficiency and load handling. Each channel supports 1 A continuous current (3 A peak), enough to power high-demand actuators like large solenoid valves (common in hydraulic systems) without requiring external relays. For example, in a heavy machinery plant, the Motorola MVME-712/M can directly control 16 hydraulic valve solenoids (each drawing 0.8 A) without additional power modules, simplifying system design. Unlike low-current modules (0.5 A per channel) that require external amplification, the Motorola MVME-712/M reduces component count and potential failure points, lowering long-term maintenance costs.

Dual-Level Isolation for Signal and System Safety: A key strength of the Motorola MVME-712/M is its 2.5 kVrms galvanic isolation between output channels and the VMEbus backplane, plus 1 kVrms isolation between channel banks. This dual-level protection prevents ground loops from damaging the central SBC (e.g., MVME-162-001) and ensures a single channel fault (e.g., a shorted solenoid) does not affect other channels. In a food processing plant, where water and cleaning chemicals increase electrical hazard risks, this isolation safeguards the entire control system from short-circuit-induced voltage spikes—critical for maintaining production continuity and operator safety.

Multi-Layer Protection for Harsh Industrial Loads: The Motorola MVME-712/M integrates comprehensive protection mechanisms to handle unpredictable industrial loads. Overcurrent protection (1.2 A per channel) automatically resets after a temporary overload (e.g., a solenoid sticking briefly), while latching short-circuit protection prevents module damage from permanent faults (e.g., a cut output wire). Over-temperature protection activates at 85°C, shutting down channels if the module overheats (common in high-load, poorly ventilated cabinets) and recovering automatically once cooled. ESD protection (±15 kV contact) also shields terminals from damage during wiring or maintenance. For users in metalworking facilities—where dust, vibration, and electrical noise are prevalent—these features ensure the Motorola MVME-712/M maintains reliable operation even in harsh conditions.

Flexible Voltage and Compatibility for Mixed Systems: The Motorola MVME-712/M supports 10-30 VDC output (compatible with most industrial power systems) and offers 5 VDC TTL configuration via DIP switches, enabling integration with legacy TTL-based devices (e.g., older indicator lights). Its sourcing (PNP) output design aligns with the common PNP actuator topology in industrial settings, ensuring plug-and-play compatibility with off-the-shelf components. It also works seamlessly with the Motorola MVME-717 digital input module: the MVME-717 monitors actuator status (e.g., a valve’s “open” limit switch), while the Motorola MVME-712/M controls the actuator—creating a closed-loop system that enhances control precision and fault detection.

Typical Application Scenarios

The Motorola MVME-712/M excels in industrial settings requiring reliable discrete output control—including manufacturing, automotive assembly, and packaging. In an automotive powertrain assembly line, it is deployed to control 16 robotic gripper solenoids. The Motorola MVME-712/M receives “grip/release” commands from the MVME-147-023 SBC (which processes input data from the MVME-717’s gripper position sensors), then sends 24 VDC signals to the solenoids. Each channel’s 1 A current capacity easily powers the grippers (drawing 0.6 A each), while overcurrent protection prevents damage if a gripper jams. The module’s ≤2 ms response time ensures grippers actuate instantly, keeping up with the line’s 60-second per-unit cycle time—critical for meeting production quotas.

In a packaging facility (e.g., snack food bagging), the Motorola MVME-712/M controls 16 bag-sealing heaters and conveyor drive relays. The MVME-162-001 SBC uses input data from the MVME-717 (monitoring bag presence and seal temperature) to send commands to the Motorola MVME-712/M: activating heaters when a bag is in position and triggering conveyors to move sealed bags. The module’s short-circuit protection prevents heater-related fires if a heating element shorts, while its wide operating temperature range (-10°C to 65°C) works in cool warehouse environments. For plant operators, the Motorola MVME-712/M’s channel-level LED indicators simplify troubleshooting—allowing quick identification of a failed heater or relay without specialized tools.

In a material handling warehouse, the Motorola MVME-712/M controls 16 conveyor diverter valves and stop cylinders. The MVME-147-023 SBC uses barcode scanner data (received via the MVME-910-3 Ethernet module) and MVME-717 sensor data (monitoring package position) to send commands to the Motorola MVME-712/M, directing packages to the correct shipping lane. The module’s 3 A peak current capacity handles the inrush current of diverter valves (drawing 2.5 A briefly when activating), while galvanic isolation protects the SBC from interference from conveyor motors. Its vibration resistance (1.5 g peak) also withstands the mechanical stress of moving conveyors, ensuring consistent valve operation and minimizing misrouted packages.

Motorola MVME-712/M

Related Model Recommendations

Motorola MVME-717: A complementary digital input module in the MVME series, designed to pair with the Motorola MVME-712/M. The MVME-717 monitors actuator status (e.g., limit switches), while the Motorola MVME-712/M controls the actuators—forming a closed-loop control system.

Motorola MVME-712: A non-isolated variant of the Motorola MVME-712/M (no galvanic isolation between channels). It is a cost-effective option for low-interference environments (e.g., laboratory automation) where isolation is not required.

Motorola MVME-147-023: An MVME series SBC that sends control commands to the Motorola MVME-712/M. The MVME-147-023 processes input data from sensors (via MVME-717) to generate precise output commands for the module.

Motorola MVME-050: An industrial power supply module that powers the Motorola MVME-712/M. Its stable +24V output (optional) ensures the module’s high-load channels (e.g., 1 A solenoids) operate without voltage drops.

Motorola MVME-121: A mixed digital I/O module that complements the Motorola MVME-712/M. The MVME-121 offers 32 inputs/32 outputs for larger systems, while the Motorola MVME-712/M provides additional high-current outputs for heavy actuators.

Motorola MVME-718: A higher-density digital output module (32 channels) in the MVME series. It is an upgrade for users needing more output channels than the Motorola MVME-712/M (16 channels) for large-scale systems (e.g., automotive assembly lines).

Motorola MVME-910-3: An Ethernet communication module that works with the Motorola MVME-712/M. It transmits the module’s output status data to upper-level SCADA systems, enabling remote monitoring of actuator operation.

Motorola MVME-162-001: A high-performance SBC that leverages the Motorola MVME-712/M’s fast response time. Its faster 68060 processor (66 MHz) sends output commands to the module more quickly than the MVME-147-023, ideal for high-speed production lines.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-712/M, verify the VMEbus chassis supports 3U modules and provides stable +5V/+12V power (add +24V if powering 1 A actuators). Gather tools: anti-static wristband (to protect output circuits from ESD), Phillips screwdriver (for chassis mounting), wire strippers (for load wiring), crimping tool (for terminal lugs), and a multimeter (to test output voltage and load current). Configure DIP switches for voltage (10-30 VDC or 5 VDC TTL) per the product manual—incorrect settings may damage actuators. Ensure the chassis is powered off, clean the VME backplane connector with a dry brush to remove dust, then align the Motorola MVME-712/M with the chassis’ guide rails and slide it into the backplane until fully seated. Secure with screws (torque to 0.4 N·m). Use 18 AWG wire for high-load channels (1 A) and label wires to match channel numbers; keep output wiring separate from power cables to reduce interference.

Maintenance suggestions: For daily upkeep of the Motorola MVME-712/M, inspect the LED indicators weekly—steady green power LED, illuminated channel LEDs (for active outputs), and no fault LED indicate normal operation. A red fault LED signals overcurrent/short-circuit; clear the fault by power-cycling the module after fixing the load issue. Clean the output terminals monthly with compressed air (low pressure, 30 PSI max) to remove dust and debris, which can cause intermittent connections. Every 6 months, check output current with a clamp meter to ensure channels are not operating near the 1 A continuous limit—derate loads if necessary to prevent overheating. If a channel fails to output, first test the actuator and wiring (replace damaged wires) and reset the module; avoid disassembling the module, as internal protection circuits are sensitive to static. Store spare Motorola MVME-712/M modules in anti-static bags in a climate-controlled environment (15°C to 25°C, 40% to 60% humidity) to preserve isolation and load-handling performance.

Service and Guarantee Commitment

The Motorola MVME-712/M is backed by a 18-month factory warranty (extendable to 48 months via premium service contracts), covering defects in materials and workmanship—including faulty output channels, isolation circuit failures, and protection mechanism malfunctions. If a defect is identified during the warranty period, we provide free replacement or repair (with a 48-hour turnaround for in-stock modules) to minimize operational downtime, as output module failures can disable critical actuators and halt production.

Our technical support team offers 24/7 assistance via email and online portals, staffed by engineers specialized in MVME series digital output modules. They can help with Motorola MVME-712/M configuration (e.g., DIP switch setup for voltage), troubleshooting fault conditions (e.g., persistent overcurrent), and verifying compatibility with actuators (e.g., current capacity matching). For legacy users, we maintain a stock of critical components (e.g., power transistors, isolation chips) to support long-term maintenance. We also offer on-site commissioning services, where technicians visit your facility to test the Motorola MVME-712/M’s output performance, verify load compatibility, and train your team on fault clearance procedures. Our commitment to the Motorola MVME-712/M extends beyond the sale—we strive to keep your discrete control systems reliable, so you can focus on optimizing industrial operations.