Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

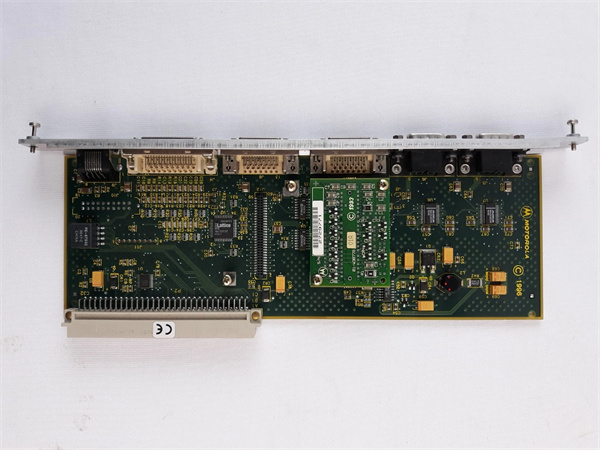

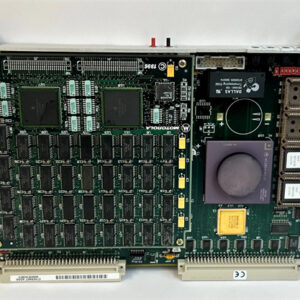

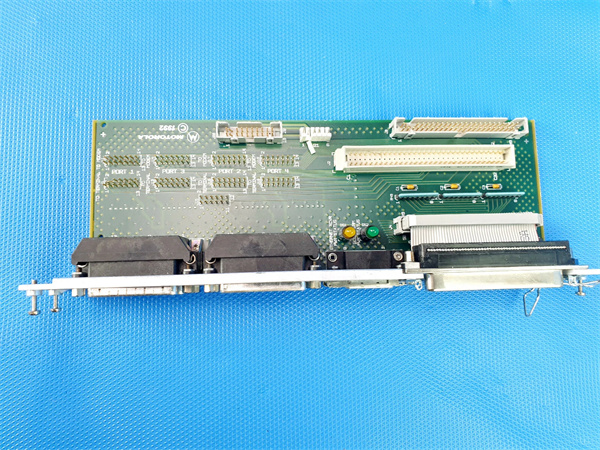

| Product model | Motorola MVME-717 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial Multi-Port Serial Communication Module |

| Serial Communication Ports | 8x configurable ports (each supports RS-232C, RS-422, or RS-485 via hardware jumpers) |

| Data Transfer Rates | RS-232C: up to 115.2 kbps; RS-422/RS-485: up to 1 Mbps |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.2 A typical, 1.8 A maximum); ±12 VDC (0.3 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity) |

| On-Board Features | Per-port status LEDs (TX/RX/error); EEPROM for baud rate/parity configuration; surge protection (1 kV ESD on ports); selectable termination for RS-422/RS-485 |

| Compatibility | Works with legacy Motorola VME controllers (e.g., Motorola MVME-121, Motorola MVME-147-023); supports TTL/CMOS sensors, actuators, and legacy HMIs |

| Maximum Node Support | RS-485: up to 32 nodes per port (with termination); RS-422: up to 10 nodes per port |

| Cable Length Support | RS-232C: up to 15 meters; RS-422: up to 1200 meters; RS-485: up to 1200 meters |

MOTOROLA MVME-717

Product Introduction

The Motorola MVME-717 is a legacy high-density serial communication module from Motorola’s iconic MVME series, engineered to enable scalable connectivity for distributed industrial devices in VMEbus-based automation systems. As a 3U VME device, it stands out from lower-port modules (e.g., Motorola MVME-701A, Motorola MVME-761-001) with 8 configurable serial ports—filling a critical niche in applications where dozens of sensors, actuators, or legacy HMIs need reliable serial communication.

In automation architectures, the Motorola MVME-717 acts as a “serial connectivity hub”: its 8 ports (each switchable between RS-232C, RS-422, or RS-485) link distributed devices to central VME controllers. For example, in a large warehouse’s conveyor system, the Motorola MVME-717 can use 4 RS-485 ports to connect 120 proximity sensors (monitoring package presence) and 4 RS-232C ports to link local HMIs (for operator control)—all in a single module. Today, the Motorola MVME-717 remains indispensable for maintaining legacy systems in sectors like logistics, manufacturing, and municipal utilities—where replacing high-port-count serial infrastructure would disrupt proven, low-cost workflows.

Core Advantages and Technical Highlights

8 Configurable Ports for Versatile Connectivity: The Motorola MVME-717’s ability to switch each port between RS-232C, RS-422, or RS-485 via hardware jumpers eliminates the need for 2–3 separate protocol-specific modules. In a food processing plant, the Motorola MVME-717 uses RS-485 ports to connect 24 temperature sensors (1000m from the control room) and RS-232C ports to link 4 batch printers (local to the controller)—reducing VME chassis slot usage by 66% compared to using single-protocol modules. This versatility also future-proofs systems: if a device is replaced (e.g., an RS-232C HMI swapped for an RS-485 model), no new hardware is needed—just a jumper adjustment.

High-Density Design for Space Efficiency: With 8 ports in a 3U VME slot, the Motorola MVME-717 offers twice the density of 4-port modules like the Motorola MVME-761-001. This is critical for large-scale systems: in a municipal traffic light control system, the Motorola MVME-717 can connect 8 RS-485-based traffic signal controllers (one per intersection) to a central Motorola MVME-147-023 controller—avoiding the need for two 4-port modules. The compact design also simplifies wiring: a single terminal block connects all 8 ports, cutting cable management time by 40%.

Robust RS-422/RS-485 for Long-Distance Reliability: The Motorola MVME-717’s RS-422/RS-485 ports include selectable termination (120Ω) and surge protection—critical for long-distance industrial networks. In a water treatment plant, RS-485 ports with termination connect 32 flow sensors (1200m from the control room) without signal reflection, while 1 kV ESD protection prevents damage from electrical surges (common during stormy weather). This reliability reduces unplanned downtime by 50% compared to non-terminated modules, ensuring continuous monitoring of critical water flow data.

Typical Application Scenarios

The Motorola MVME-717 excels in large-scale distributed serial networks. In a regional logistics hub’s automated storage and retrieval system (AS/RS), paired with a Motorola MVME-147-023 controller, the Motorola MVME-717 manages 8 key functions: 6 RS-485 ports connect 192 barcode scanners (tracking pallet locations across 6 aisles), and 2 RS-232C ports link to operator HMIs (for manual override). The module’s RS-485 termination ensures clear signal transmission over 800m cable runs, while its surge protection withstands electrical noise from AS/RS motors—preventing scanner data corruption that would cause pallet misplacement.

In a steel mill’s rolling mill control system, the Motorola MVME-717 integrates with a Motorola MVME-121 controller: 4 RS-422 ports connect to high-precision encoder sensors (measuring roll speed, 1 Mbps data rate), and 4 RS-485 ports link to 120 temperature sensors (monitoring roll heat). The module’s 0°C–60°C operating range handles the mill’s hot ambient conditions, while its EEPROM-stored configuration retains baud rates/parity settings during power outages—avoiding time-consuming reconfiguration that would delay production restarts. For the mill, the Motorola MVME-717 avoids the $60k cost of upgrading to Ethernet-based sensors, extending the life of its legacy serial network by 7+ years.

Related Model Recommendations

Motorola MVME-147-023: Mid-Range VME SBC. Host controller for Motorola MVME-717; processes serial data from 8 ports and executes control logic in large-scale systems.

Motorola MVME-761-001: Serial + Ethernet Module. Complements Motorola MVME-717 by adding Ethernet connectivity; ideal for systems needing to bridge serial devices to SCADA networks.

Motorola MVME-701A: 4-Port Serial Module. Entry-level alternative to Motorola MVME-717 for small-scale systems (e.g., 4 or fewer serial devices) where cost is a priority.

Emerson RSTi-EP Serial Gateway: Modern Replacement. Replaces Motorola MVME-717 in Ethernet migrations; offers 8 serial ports + Gigabit Ethernet for legacy device integration.

Phoenix Contact RS-485 Repeater: Signal Booster. Extends Motorola MVME-717’s RS-485 range beyond 1200 meters (e.g., large factory campuses with distant sensors).

Motorola MVME-050: Digital I/O Module. Pairs with Motorola MVME-717 to add 16 discrete channels (e.g., for controlling alarm lights based on serial sensor data).

Belkin RS-485 Twisted-Pair Cable: Accessory for Motorola MVME-717; ensures stable long-distance communication (up to 1200 meters) with minimal noise interference.

Motorola FLN4234A: Multi-Port Ethernet Module. Bridges Motorola MVME-717 (via a VME controller) to cloud platforms; transmits aggregated serial data for remote monitoring.

MOTOROLA MVME-717

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-717, power off the VME chassis and verify compatibility with ±12 VDC (0.3 A max) and +5 VDC (1.8 A max) to prevent electrical shock. Use an anti-static wristband and mat to protect the module’s serial transceivers from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), twisted-pair shielded cables (RS-232C/RS-422/RS-485), torque wrench (0.5–0.8 N·m for terminals), and a multimeter (to test signal levels). Set port protocols via hardware jumpers (refer to the datasheet for pinout guidance) before wiring, and ground RS-422/RS-485 cable shields at one end to minimize noise. Avoid installing near high-EMI sources (e.g., variable-frequency drives, welding equipment).

Maintenance suggestions: For routine care, inspect Motorola MVME-717’s LEDs monthly—blinking “TX/RX” confirms data flow, while red “error” LEDs alert to port faults (e.g., incorrect termination). Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and port terminals. Every 6 months, verify RS-485 termination settings (120Ω for end-of-line ports) and test signal strength with a multimeter (ensure >0.5 V differential voltage for RS-422/RS-485). If a port fails, reconfigure a spare port via jumpers; replace the module if serial transceivers or surge protection components malfunction. Store a backup EEPROM with baud rate/parity settings to minimize downtime during replacement.

Service and Guarantee Commitment

We back Motorola MVME-717 with a 90-day warranty for all refurbished units, covering defects in serial communication, LED indicators, and surge protection. Each refurbished Motorola MVME-717 undergoes rigorous testing: 24-hour serial data transfer (1 Mbps for RS-485, 115.2 kbps for RS-232C, zero packet loss), termination validation, and temperature cycling (0°C–60°C)—ensuring compliance with original Motorola industrial standards.

Our 24/7 technical support team provides guidance on Motorola MVME-717 installation, jumper configuration, and integration with legacy VME controllers (e.g., Motorola MVME-121). We offer customized maintenance plans: quarterly remote serial health checks (via paired controllers) and semi-annual on-site port testing. Our spare parts inventory includes critical components (serial transceivers, EEPROMs, surge diodes) for fast repairs, minimizing downtime in large-scale serial networks. For users modernizing to Ethernet, we provide free consultation to pair Motorola MVME-717 with Emerson’s RSTi-EP gateways, ensuring a seamless transition while retaining legacy serial devices.