Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | MVME-761-001 |

| Manufacturer | Motorola (now integrated into Emerson’s industrial automation product portfolio) |

| Product category | Industrial Analog I/O Module (VMEbus-compatible, mixed analog input/output) |

| Analog Input Channels | 16 differential input channels; configurable for voltage or current signals |

| Analog Input Ranges | Voltage: ±5V, ±10V; Current: 4-20 mA, 0-20 mA (selectable per channel via software) |

| Analog Output Channels | 8 channels; voltage or current output (configurable per channel) |

| Analog Output Ranges | Voltage: ±5V, ±10V; Current: 4-20 mA, 0-20 mA |

| Signal Resolution | Input: 12-bit ADC (Analog-to-Digital Converter); Output: 12-bit DAC (Digital-to-Analog Converter) |

| Accuracy | Input: ±0.1% full-scale (FS) at 25°C; Output: ±0.2% FS at 25°C |

| Bus Compatibility | Complies with VMEbus IEEE 1014-1987 standard (3U form factor); supports VMEbus A16/D16 and A24/D16 address cycles |

| Environmental Requirements | Operating temperature: -5°C to 60°C (23°F to 140°F); Storage temperature: -40°C to 85°C (-40°F to 185°F); Relative humidity: 5% to 95% (non-condensing); Vibration resistance: 10-500 Hz, 1.0 g (rms) |

| Physical Size | 3U VMEbus form factor (100 mm x 160.02 mm / 3.94 in x 6.30 in); weight: 175 g (0.38 lbs) |

| Installation Method | VMEbus backplane mounting; compatible with 3U/6U VME chassis; requires VMEbus standard power supply (+5V, ±12V) |

| Protection Features | Input overvoltage protection (±30V for voltage inputs); reverse polarity protection (current inputs); ESD protection (±15 kV contact) on I/O terminals |

| Diagnostic Features | Built-in self-test (BIST) function; LED indicators for module power, input/output status, and BIST results; overrange detection for input channels |

| Power Consumption | Typical: 7 W (at 25°C, full channel operation); Maximum: 9 W |

| Compatibility | Optimized for MVME series single-board computers (e.g., MVME-147-023, MVME-162-001); works with MVME power modules (MVME-050) and communication modules (MVME-910-3) |

| Isolation | Optical isolation (2.5 kVrms) between analog I/O circuits and VMEbus backplane; prevents ground loops and electrical interference |

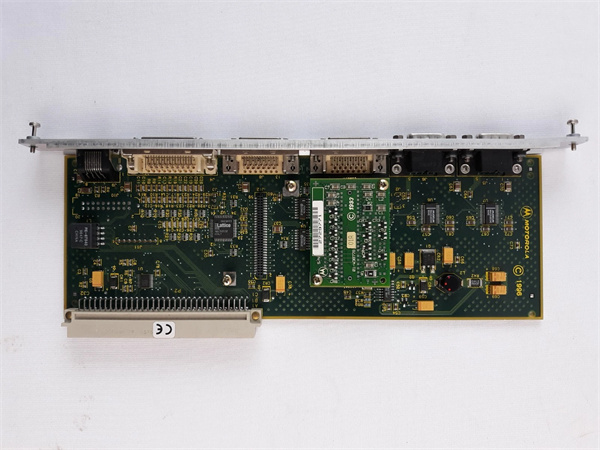

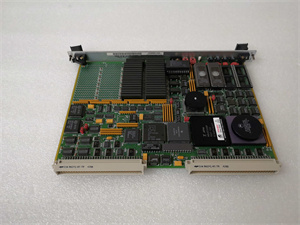

Motorola MVME-761-001

Product Introduction

The Motorola MVME-761-001 is a high-precision industrial analog I/O module developed by Motorola—a pioneer in legacy industrial automation hardware—and now part of Emerson’s trusted product ecosystem. As a core mixed-signal solution in the MVME series, it is engineered to convert analog signals (from sensors like temperature probes or pressure transducers) into digital data for VMEbus controllers, and vice versa (digital commands to analog signals for actuators like valves or variable-speed drives).

Designed to address the need for accurate analog signal processing in industrial environments, the Motorola MVME-761-001 features 16 differential analog inputs and 8 analog outputs, all with 12-bit resolution and optical isolation. In automation architectures, the Motorola MVME-761-001 acts as a “signal translator”—it connects analog field devices to MVME series single-board computers (such as the MVME-147-023) and communication modules (like the MVME-910-3). For example, it converts 4-20 mA current signals from a pressure sensor into digital data for the MVME-147-023 to process, then sends analog 0-10V commands to a control valve via its output channels. Its optical isolation ensures signal integrity in noisy electrical environments, making it indispensable for process control industries like chemical manufacturing and oil refining.

Core Advantages and Technical Highlights

High-Precision Signal Conversion for Critical Measurements: The Motorola MVME-761-001 delivers 12-bit resolution for both analog inputs and outputs, paired with ±0.1% full-scale (FS) accuracy for inputs—ensuring precise capture of subtle analog signal variations (e.g., a 0.1 psi change in a pressure sensor). This level of precision is critical for industries like pharmaceutical manufacturing, where even small deviations in temperature or pressure can compromise product quality. Unlike lower-resolution modules (8-bit or 10-bit), the Motorola MVME-761-001 eliminates “signal rounding” errors, allowing the MVME-162-001 SBC to make accurate control decisions—such as adjusting a heating element to maintain a ±0.5°C temperature range in a reactor.

Flexible Channel Configuration for Diverse Applications: The Motorola MVME-761-001 offers software-configurable input/output ranges, enabling each channel to adapt to different signal types without hardware modifications. For instance, one input channel can be set to 4-20 mA (for a flow meter), while another is configured to ±10V (for a temperature transmitter); output channels can switch between 0-20 mA (for a pump) and ±5V (for a small actuator). This flexibility eliminates the need to stock multiple specialized modules, simplifying inventory management and reducing costs. For users with mixed analog devices (e.g., a water treatment plant with pH sensors, flow meters, and chemical dosing valves), the Motorola MVME-761-001 provides a single, versatile solution.

Robust Isolation and Protection for Uninterrupted Operation: A standout feature of the Motorola MVME-761-001 is its 2.5 kVrms optical isolation between analog circuits and the VMEbus backplane—preventing ground loops that commonly disrupt analog signals in industrial settings (e.g., near large motors or variable frequency drives). It also includes input overvoltage protection (±30V) and ESD protection (±15 kV contact), shielding the module from damage caused by accidental wiring errors or electrostatic discharge. For example, in a chemical plant, if a technician mistakenly connects a 24V power supply to an input channel, the Motorola MVME-761-001’s overvoltage protection will prevent internal component failure, avoiding unplanned downtime for process control systems.

Typical Application Scenarios

The Motorola MVME-761-001 excels in industrial settings requiring accurate analog signal processing—including chemical manufacturing, food and beverage processing, and HVAC for large facilities. In chemical manufacturing, it is deployed in batch reactor control systems, working alongside the MVME-147-023 SBC and MVME-910-3 Ethernet module. The Motorola MVME-761-001’s input channels monitor analog signals from a temperature probe (±10V), pressure transducer (4-20 mA), and level sensor (0-20 mA), converting them to digital data for the MVME-147-023 to analyze. Its output channels send 4-20 mA commands to a heating element (to maintain reactor temperature) and a control valve (to regulate chemical feed rate). The MVME-910-3 then transmits real-time reactor data to a central SCADA system, ensuring compliance with safety and quality standards.

In food and beverage processing (e.g., dairy pasteurization), the Motorola MVME-761-001 ensures precise temperature control—critical for eliminating harmful bacteria while preserving product quality. Its input channels read 4-20 mA signals from a platinum resistance thermometer (RTD) in the pasteurization tank, with 12-bit resolution capturing temperature changes as small as 0.1°C. The MVME-147-023 uses this data to adjust a steam valve via the Motorola MVME-761-001’s 0-10V output channel, maintaining the tank at 72°C for the required 15 seconds. The module’s optical isolation protects against electrical interference from nearby pumps, ensuring consistent temperature readings—avoiding product spoilage or regulatory non-compliance.

For HVAC systems in large commercial buildings (e.g., shopping malls), the Motorola MVME-761-001 manages heating, cooling, and air quality. Its input channels monitor 0-10V signals from temperature sensors (across building zones) and 4-20 mA signals from CO₂ detectors, while output channels send 4-20 mA commands to variable air volume (VAV) boxes and chiller valves. The MVME-162-001 SBC processes this data to optimize energy use—for example, reducing cooling in unoccupied zones—while the MVME-910-3 shares HVAC status with a building management system (BMS). The Motorola MVME-761-001’s wide operating temperature range (-5°C to 60°C) allows it to function reliably in mechanical rooms with varying heat levels.

Motorola MVME-761-001

Related Model Recommendations

Motorola MVME-761-002: A sibling model in the MVME-761 series, with 8 analog input channels and 4 analog output channels (half the density of the Motorola MVME-761-001). It is a cost-effective option for small-scale systems (e.g., standalone HVAC units).

Motorola MVME-147-023: A complementary MVME series SBC that processes data from the Motorola MVME-761-001. The MVME-147-023 uses the module’s digitalized analog data to execute control logic for field devices.

Motorola MVME-050: An industrial power supply module that powers the Motorola MVME-761-001. Its stable ±12V output ensures the module’s ADC/DAC circuits operate with minimal noise, preserving signal accuracy.

Motorola MVME-910-3: An Ethernet communication module that works with the Motorola MVME-761-001. It transmits the module’s analog I/O data to upper-level SCADA/BMS systems via Ethernet, enabling remote monitoring.

Motorola MVME-121: A digital I/O module that complements the Motorola MVME-761-001. The MVME-121 handles discrete signals (e.g., limit switches), while the MVME-761-001 manages analog signals—providing mixed I/O control.

Motorola MVME-762-001: A high-resolution variant of the Motorola MVME-761-001, with 16-bit ADC/DAC (vs. 12-bit). It is ideal for applications requiring ultra-precise measurements (e.g., laboratory-grade process control).

Motorola MVME-162-001: A high-performance SBC that leverages the Motorola MVME-761-001’s data. Its faster 68060 processor (66 MHz) processes large volumes of analog data more efficiently than the MVME-147-023, suitable for high-speed process control.

Motorola MVME-1331: A serial communication module that pairs with the Motorola MVME-761-001. It transmits the module’s data to legacy serial-based HMIs, supporting facilities with mixed Ethernet/serial infrastructure.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME-761-001, verify the VMEbus chassis supports 3U modules and provides stable +5V/±12V power (use a multimeter to check voltage tolerance within ±5%). Gather tools: anti-static wristband (to protect ADC/DAC circuits from ESD), Phillips screwdriver (for chassis mounting), wire strippers (for analog wiring), and a multimeter (to test signal continuity). Ensure the chassis is powered off, then clean the VME backplane connector with a dry, lint-free cloth to remove dust—debris can cause electrical noise in analog signals. Align the Motorola MVME-761-001 with the chassis’ guide rails, slide it into the backplane until fully seated, and secure with screws (torque to 0.4 N·m). Use twisted-pair cables for analog wiring (to reduce interference) and keep wiring separate from power cables.

Maintenance suggestions: For daily upkeep of the Motorola MVME-761-001, inspect the LED indicators weekly—steady green power LED, illuminated input/output LEDs (for active channels), and no fault LED indicate normal operation. Run the built-in self-test (BIST) monthly via the MVME-147-023 SBC to verify ADC/DAC functionality; a BIST failure signals the need for calibration. Every 6 months, calibrate the module using a precision signal generator (e.g., 4-20 mA, ±10V) to maintain ±0.1% input accuracy—follow the product manual’s calibration procedure to avoid damaging sensitive circuits. If an input channel fails, first check the wiring (replace twisted-pair cable if damaged) and test the connected sensor; avoid disassembling the module, as internal isolation circuits are sensitive to static. Store spare Motorola MVME-761-001 modules in anti-static bags in a climate-controlled environment (15°C to 25°C, 40% to 60% humidity) to preserve ADC/DAC performance.

Service and Guarantee Commitment

The Motorola MVME-761-001 is backed by a 18-month factory warranty (extendable to 48 months via premium service contracts), covering defects in materials and workmanship—including ADC/DAC inaccuracies, isolation circuit failures, and LED malfunctions. If a defect is identified during the warranty period, we provide free replacement or repair (with a 48-hour turnaround for in-stock modules) to minimize operational downtime, as analog I/O failures can disrupt critical process control.

Our technical support team offers 24/7 assistance via email and online portals, staffed by engineers specialized in MVME series analog modules. They can help with Motorola MVME-761-001 configuration (e.g., input/output range setup, BIST activation), calibration guidance, and troubleshooting signal noise issues (e.g., ground loop mitigation). For legacy users, we maintain a stock of critical components (e.g., 12-bit ADC chips, optical isolators) to support long-term maintenance. We also offer on-site commissioning services, where technicians visit your facility to test the Motorola MVME-761-001’s signal accuracy, verify wiring, and train your team on calibration best practices. Our commitment to the Motorola MVME-761-001 extends beyond the sale—we strive to keep your analog control systems precise and reliable, so you can focus on optimizing industrial operations.