Description

Motorola MVME5100 Product Description

Detailed parameter table

| Parameter name | Parameter value |

|---|---|

| Product model | MVME5100 |

| Manufacturer | Motorola |

| Product category | VMEbus single – board computer |

| Processor | Freescale MPC8540 PowerQUICC III processor at 1 GHz |

| Memory | 1 GB DDR2 SDRAM (expandable to 2 GB) |

| Storage | 16 MB Flash, 1 x CompactFlash socket |

| Communication interfaces | 4 x Gigabit Ethernet, 2 x RS – 232 serial ports, 1 x CAN bus |

| VMEbus interface | VME64x compliant, supports A32/D32, A64/D64 addressing |

| Expansion slots | 2 x PMC/XMC slots |

| Operating temperature | 0°C – 55°C (extended options available) |

| Dimensions | 160 mm x 233.35 mm (6U VME form factor) |

| Power consumption | 35 W (typical) |

| Certifications | CE, UL, RoHS compliant |

Product introduction

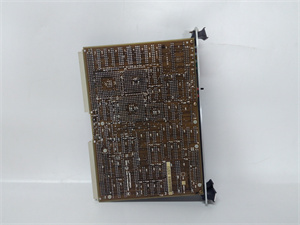

The Motorola MVME5100 is a high – performance VMEbus single – board computer designed for mission – critical industrial automation, aerospace, and defense applications. As part of Motorola’s PowerQUICC III family, the MVME5100 delivers exceptional processing power, advanced I/O capabilities, and rugged reliability in harsh environments.

Powered by the Freescale MPC8540 processor clocked at 1 GHz, the MVME5100 combines a dual – core PowerPC e500 core with integrated communication and networking engines. With 1 GB of DDR2 SDRAM (expandable to 2 GB) and 16 MB of Flash memory, it provides ample resources for running complex real – time operating systems (RTOS) and application software. The module’s 4 Gigabit Ethernet ports, 2 serial ports, and CAN bus interface enable seamless integration into diverse industrial networks, while the 2 PMC/XMC slots allow for flexible expansion with specialized I/O or communication modules. In automation systems, the MVME5100 serves as a central controller, managing data acquisition, processing, and communication between field devices and higher – level systems.

Motorola MVME5100

Motorola MVME5100

Core advantages and technical highlights

High – performance processing architecture

The MVME5100‘s MPC8540 processor features dual e500 cores with integrated floating – point units, delivering up to 2.0 DMIPS/MHz performance. This enables it to handle complex control algorithms, high – speed data processing, and multitasking requirements in real – time applications. The integrated communication processors (CPUs) offload network traffic, reducing CPU overhead and improving overall system efficiency.

Advanced I/O and connectivity

With 4 Gigabit Ethernet ports, the MVME5100 supports high – speed data transfer for applications such as industrial Ethernet protocols (Profinet, Ethernet/IP), networked sensor arrays, and distributed control systems. The CAN bus interface provides reliable communication for automotive, aerospace, and industrial control networks, while the 2 PMC/XMC slots allow for expansion with modules such as Fiber Channel, Serial RapidIO, or custom I/O interfaces.

Rugged design for harsh environments

Designed to operate in industrial and military environments, the MVME5100 features a ruggedized design with conformal coating options, extended temperature support (0°C – 55°C standard, – 40°C – 85°C optional), and resistance to vibration and shock. The VME64x interface ensures reliable mechanical and electrical connections in high – stress environments, making it suitable for applications in aerospace, transportation, and heavy industrial settings.

Scalable and future – proof

The MVME5100‘s modular design and support for PMC/XMC expansions provide scalability for evolving application requirements. The use of industry – standard VMEbus and PMC interfaces ensures compatibility with existing systems and simplifies upgrades. Additionally, Motorola’s long – term product support and firmware updates help extend the product lifecycle, protecting customer investments.

Typical application scenarios

Industrial automation

In industrial automation systems, the Motorola MVME5100 serves as a central controller for managing complex manufacturing processes. It can interface with PLCs, robotic arms, and sensors via its multiple Ethernet ports, enabling real – time monitoring and control of production lines. For example, in automotive manufacturing, the MVME5100 can coordinate the movement of robotic assembly stations, process quality control data from vision systems, and communicate with enterprise resource planning (ERP) systems.

Aerospace and defense

The MVME5100‘s rugged design and high – performance processing make it ideal for aerospace and defense applications. It can be used in avionics systems for flight control, navigation, and data processing, as well as in ground – based radar and communication systems. The module’s support for safety – critical applications and compliance with military standards ensure reliable operation in mission – critical scenarios.

Transportation

In transportation systems, such as rail and mass transit, the MVME5100 provides control and monitoring capabilities for traction systems, signaling, and passenger information systems. Its ability to operate in wide temperature ranges and withstand vibration ensures reliable performance in harsh environments. The CAN bus interface is particularly useful for communicating with vehicle subsystems and sensors.

Related model recommendations

MVME3100

A related VMEbus SBC from Motorola, the MVME3100 features a similar PowerQUICC III processor architecture but with different I/O configurations. It offers 2 PMC slots and 4 Gigabit Ethernet ports, making it suitable for applications requiring high – speed network connectivity. The MVME3100 is often used in networking and communication applications, while the MVME5100 focuses more on industrial control and automation.

MVME5500

The MVME5500 is a higher – performance variant in the same product family, featuring a more powerful MPC8548 processor and additional memory options. It is designed for applications requiring maximum processing power, such as high – speed data acquisition and real – time analytics. The MVME5500 is often used as an upgrade path for systems that outgrow the capabilities of the MVME5100.

MVME167 – 012

A legacy VMEbus SBC, the MVME167 – 012 uses a different processor architecture (PowerPC 604e) and offers lower performance compared to the MVME5100. It is still used in some legacy systems where compatibility and cost are key considerations. The MVME5100 provides a modern upgrade path for such systems, offering improved performance, memory, and I/O capabilities.

MVME7124

The MVME7124 is a VMEbus I/O module designed to work in conjunction with processor boards like the MVME5100. It provides a variety of I/O interfaces, including digital inputs/outputs, analog inputs, and serial ports. The MVME7124 extends the I/O capabilities of the MVME5100, making it suitable for applications requiring extensive I/O integration.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the Motorola MVME5100, ensure the VMEbus backplane is powered off and grounded. Use anti – static precautions when handling the module to prevent electrostatic discharge (ESD) damage. Verify that the backplane slot is compatible with the VME64x interface and that the power supply meets the module’s requirements (35 W typical, +5 VDC and +12 VDC). Align the module carefully with the backplane slot and secure it using the front – panel mounting hardware.

Commissioning

After installation, power on the system and monitor the boot process using the console port. Verify that the operating system loads correctly and that all hardware components are detected. Configure the network interfaces, serial ports, and other peripherals as required by the application. Run diagnostic tests to validate the functionality of the module, including memory tests, network connectivity tests, and I/O tests.

Maintenance suggestions

Regularly inspect the MVME5100 for signs of physical damage, such as loose connectors or corrosion. Clean the module using compressed air to remove dust and debris, especially from the ventilation areas. Periodically update the firmware to ensure compatibility with the latest operating systems and applications. In case of component failure, replace faulty parts (such as memory modules or PMC cards) with genuine Motorola components. Keep a record of maintenance activities and firmware updates for traceability.

Service and guarantee commitment

Motorola stands behind the Motorola MVME5100 with a comprehensive warranty and technical support program. Each module undergoes rigorous testing and quality control before shipment to ensure compliance with industry standards and specifications. Motorola offers a standard warranty period, with options for extended coverage. Technical support is available through Motorola’s global network of experts, providing assistance with installation, configuration, and troubleshooting. Motorola also offers firmware updates and software support to enhance the performance and functionality of the MVME5100 throughout its lifecycle. This commitment to quality and support ensures that customers can rely on the MVME5100 for their critical industrial and military applications.