Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

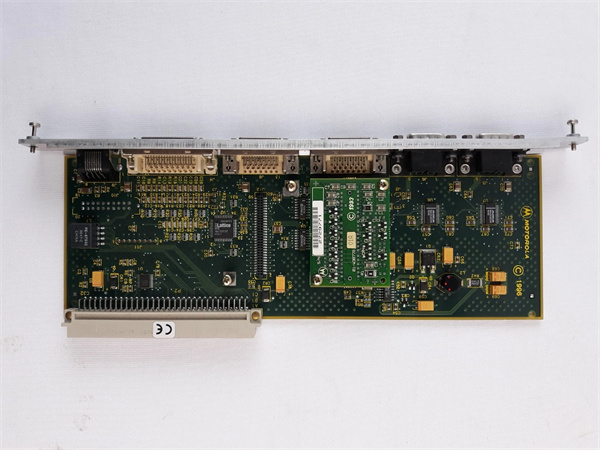

| Product model | Motorola MVME-761-001 |

| Manufacturer | Motorola (now part of Emerson’s Industrial Automation Portfolio) |

| Product category | VMEbus Industrial High-Speed Serial & Network Interface Module |

| Serial Communication Ports | 4x RS-422/RS-485 ports (software-configurable); 2x RS-232C ports (DTE mode) |

| Network Protocol Support | TCP/IP (Ethernet 10Base-T); supports UDP, Telnet, and FTP for data transfer |

| Data Transfer Rates | RS-422/RS-485: up to 2 Mbps; RS-232C: up to 115.2 kbps; Ethernet: 10 Mbps |

| Bus Standard | VMEbus 1.4 compliant (16-bit address/data bus); slave-only mode |

| Physical Dimensions | Standard 3U VME form factor (100 mm × 160 mm × 16 mm; L×W×H) |

| Power Requirements | +5 VDC (1.0 A typical, 1.5 A maximum); ±12 VDC (0.4 A typical each) |

| Operating Temperature Range | 0°C – 60°C (32°F – 140°F); Storage: -20°C – 70°C (-4°F – 158°F) |

| Compliance Standards | FCC Class A (EMI), CE, RoHS, IEC 61000-6-2 (Industrial EMC Immunity), IEEE 802.3 |

| On-Board Features | Per-port status LEDs (serial: TX/RX/error; Ethernet: link/activity); EEPROM for IP configuration; hardware watchdog timer |

| Compatibility | Works with legacy Motorola VME controllers (e.g., Motorola MVME-121, Motorola MVME-147-023); supports TTL/CMOS sensors and Ethernet-enabled SCADA systems |

| Maximum Node Support | RS-485: up to 32 nodes per port; Ethernet: up to 254 devices per subnet |

MOTOROLA MVME-761-001

Product Introduction

The Motorola MVME-761-001 is a legacy multi-functional communication module from Motorola’s iconic MVME series, engineered to bridge VMEbus-based control systems with both serial devices and Ethernet networks. As a 3U VME device, it fills a unique gap between basic serial modules (e.g., Motorola MVME-701A) and full-featured Ethernet gateways—offering a rare combination of high-speed serial connectivity and entry-level TCP/IP support for legacy automation systems transitioning to networked monitoring.

In automation architectures, the Motorola MVME-761-001 acts as a “hybrid communication hub”: its RS-422/RS-485 ports connect to distributed sensors (e.g., remote pressure transducers, conveyor speed encoders) across factory floors, while the Ethernet port transmits aggregated data to SCADA systems or cloud platforms for remote oversight. For example, in a regional packaging plant, the Motorola MVME-761-001 can collect production data from 16 RS-485-based barcode scanners and send real-time batch logs to a central Ethernet-connected HMI (paired with Motorola MVME-147-023). Today, it remains a critical component for maintaining legacy Motorola VME systems in sectors like food processing, municipal utilities, and small-scale manufacturing—where full network overhauls are cost-prohibitive but remote data access is essential.

Core Advantages and Technical Highlights

Hybrid Serial + Ethernet Connectivity: The Motorola MVME-761-001’s integration of 4 high-speed serial ports and 10Base-T Ethernet eliminates the need for separate serial modules and Ethernet gateways, reducing VME chassis slot usage by 50%. In a water treatment plant, the Motorola MVME-761-001 uses 2 RS-485 ports to monitor 12 pump pressure sensors (2 Mbps, low-latency) and its Ethernet port to send hourly flow rate reports to a city’s SCADA system—avoiding the complexity of adding a standalone Ethernet module. This hybrid design cuts wiring costs by 30% and simplifies system troubleshooting.

High-Speed Serial for Time-Sensitive Data: Unlike slower RS-232C-focused modules, the Motorola MVME-761-001’s RS-422/RS-485 ports support up to 2 Mbps—critical for capturing fast-changing industrial signals. In a candy manufacturing line, the module uses RS-422 to collect data from 8 high-speed temperature sensors (sampling every 100 ms) on a caramel cooker, ensuring precise heat control to prevent burning. This speed is 2x faster than basic RS-485 modules, making it ideal for processes where delayed data could ruin products.

Simplified Legacy-to-Network Transition: The Motorola MVME-761-001’s built-in TCP/IP support lets legacy VME systems connect to modern Ethernet networks without replacing controllers. Its EEPROM-stored IP configuration eliminates the need for complex software setup—technicians can set the module’s IP address via a serial terminal, then pair it with existing controllers like the Motorola MVME-121. In a small electronics factory, this means the plant can retain its 20-year-old VME control system while adding remote monitoring via a cloud dashboard—avoiding a $50k+ upgrade to new hardware.

Typical Application Scenarios

The Motorola MVME-761-001 excels in legacy systems needing both local serial control and remote network access. In a regional dairy’s milk bottling plant (paired with Motorola MVME-147-023), the Motorola MVME-761-001 manages two key tasks: 3 RS-485 ports connect to fill-level sensors on 12 bottling machines (2 Mbps, real-time feedback to adjust fill volumes), and the Ethernet port sends daily production totals (via FTP) to the dairy’s headquarters for inventory tracking. The module’s watchdog timer also ensures connectivity—if the Ethernet link drops, it triggers a local alarm to alert staff, preventing data loss.

In a municipal wastewater treatment plant’s pump station, the Motorola MVME-761-001 integrates with a Motorola MVME-121 controller: 2 RS-485 ports monitor 8 pump vibration sensors (500m from the control room, via RS-485’s long-range capability), and the Ethernet port transmits pump runtime data to the city’s remote SCADA system. The module’s EMC immunity resists interference from nearby high-voltage pumps, ensuring stable sensor readings, while its 0°C–60°C operating range handles seasonal temperature swings. For the plant, the Motorola MVME-761-001 avoids the $30k cost of a new Ethernet-based control system, extending the life of its legacy VME setup by 5+ years.

MOTOROLA MVME-761-001

Related Model Recommendations

Motorola MVME-147-023: Mid-Range VME SBC. Host controller for Motorola MVME-761-001; processes serial data and coordinates Ethernet transmissions in mid-scale systems.

Motorola MVME-701A: Basic Serial Module. Complements Motorola MVME-761-001 by adding 4 extra RS-232C ports for low-speed devices (e.g., barcode printers, legacy HMIs).

Motorola MVME-910-3: Fieldbus Communication Module. Upgrade for Motorola MVME-761-001 when PROFIBUS-DP/DeviceNet support is needed (e.g., factory-wide fieldbus networks).

Emerson RSTi-EP Ethernet Gateway: Modern Replacement. Replaces Motorola MVME-761-001 in full network overhauls; offers Gigabit Ethernet and support for modern protocols like MQTT.

Motorola FLN4234A: Multi-Port Ethernet Module. Bridges Motorola MVME-761-001 to additional Ethernet devices; adds 4 extra Ethernet ports for large-scale SCADA integration.

Phoenix Contact RS-485 Repeater: Signal Booster. Extends Motorola MVME-761-001’s RS-485 range beyond 1200 meters (e.g., large factory campuses with distributed sensors).

Motorola MVME-050: Digital I/O Module. Pairs with Motorola MVME-761-001 to add 16 discrete channels (e.g., for controlling alarm lights or small relays based on network data).

Belkin 10Base-T Ethernet Cable: Accessory for Motorola MVME-761-001; ensures stable Ethernet connectivity between the module and SCADA systems (up to 100 meters).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME-761-001, power off the VME chassis and verify compatibility with ±12 VDC (0.4 A max) and +5 VDC (1.5 A max) to prevent electrical shock. Use an anti-static wristband and mat to protect the module’s Ethernet chip and serial transceivers from ESD damage. Gather tools: Phillips-head screwdriver (chassis mounting), twisted-pair shielded cables (RS-422/RS-485), Cat5 Ethernet cable, torque wrench (0.5–0.8 N·m for terminals), and a serial terminal (to set the IP address). Ground RS-485 cable shields at one end to reduce noise, and avoid installing near variable-frequency drives or welding equipment (high EMI sources).

Maintenance suggestions: For routine care, inspect Motorola MVME-761-001’s LEDs monthly—steady green Ethernet “link” LED confirms network connectivity, while blinking “activity” LED indicates data transfer; serial “TX/RX” LEDs confirm sensor communication. Clean the module quarterly with compressed air (low pressure) to remove dust from the VME connector and Ethernet port. Every 6 months, verify the IP configuration via a serial terminal to ensure it hasn’t changed (critical for remote access), and test RS-485 signal strength with a multimeter (ensure >0.5 V differential voltage). If an Ethernet port fails, reset the module via the hardware reset switch; replace the module if serial transceivers or the Ethernet chip malfunction. Store a backup EEPROM with the module’s IP and protocol settings to minimize downtime during replacement.

Service and Guarantee Commitment

We back Motorola MVME-761-001 with a 90-day warranty for all refurbished units, covering defects in serial/Ethernet communication, LED indicators, and watchdog timer functionality. Each refurbished Motorola MVME-761-001 undergoes rigorous testing: 24-hour Ethernet data transfer (10 Mbps, zero packet loss), RS-485 speed validation (2 Mbps, 10k data frames), and temperature cycling (0°C–60°C)—ensuring compliance with original Motorola and IEEE 802.3 standards.

Our 24/7 technical support team provides guidance on Motorola MVME-761-001 installation, IP configuration, and integration with legacy VME controllers (e.g., Motorola MVME-121). We offer customized maintenance plans: quarterly remote network health checks (via ping and Telnet) and semi-annual on-site serial/Ethernet testing. Our spare parts inventory includes critical components (serial transceivers, Ethernet chips, EEPROMs) for fast repairs, minimizing downtime in network-critical systems. For users modernizing to Gigabit Ethernet, we provide free consultation to pair Motorola MVME-761-001 with Emerson’s RSTi-EP gateways, ensuring a seamless transition while retaining legacy serial devices.