Description

Detailed Parameter Table

| Parameter name | Parameter value |

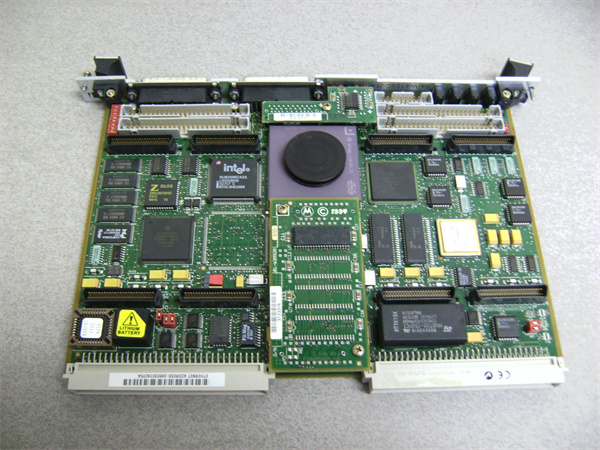

| Product model | Motorola MVME162-432 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus Entry-Level Mid-Tier Real-Time Single-Board Computer (SBC) |

| Processor | 25 MHz Motorola MC68030 32-bit microprocessor; 2 KB L1 cache (1 KB instruction/1 KB data), Basic MMU (Memory Management Unit); No FPU (Floating-Point Unit) |

| Memory Configuration | 8 MB shared DRAM (no parity); 256 KB battery-backed SRAM (non-volatile); 512 KB EPROM (firmware only, no debugger support) |

| Communication Interfaces | 1x serial port (EIA-232-D DTE console only); 1x optional EIA-422 serial port (factory-installable); No Ethernet support |

| Expansion Interfaces | 2x 8/16-bit Industry Pack® ports (no DMA channels); VMEbus A16/D16 master/slave (IEEE 1014-1987 compliant, limited address range) |

| Environmental Ratings | Operating temperature: 0°C–60°C (32°F–140°F); Storage temperature: -40°C–85°C (-40°F–185°F); Humidity: 10%–90% (non-condensing); Vibration: 10–2000 Hz, 1.2 g (rms); Shock: 40 g (peak, 1 ms) |

| Physical Dimensions | Double-high 6U VME form factor: 233.4mm × 160mm × 27mm (9.19in × 6.30in × 1.06in); Weight: 730 g (1.61 lbs) |

| Power Consumption | Typical: 15 W (25°C, no Industry Pack modules); Maximum: 22 W (both Industry Pack ports active, optional serial port installed) |

| Diagnostic Features | LED indicators (power, processor activity, SRAM status); Basic VMEbus error detection (no interrupt handler); No watchdog timer |

| Compatible Peripherals | Motorola IP-210 (8/16-bit digital I/O Industry Pack), Motorola MVME-340A (legacy serial module), Motorola MVME-177-001 (basic analog input) |

| Product Life Cycle | Discontinued/Obsolete (1990s production) |

Motorola MVME162-432

Product Introduction

The Motorola MVME162-432 is a legacy industrial VMEbus entry-level mid-tier real-time SBC designed for cost-sensitive 1990s-era basic automation tasks—serving as a streamlined predecessor to the more capable Motorola MVME162-510 (faster processor, optional FPU). Unlike its successor, Motorola MVME162-432 relies on a 25 MHz MC68030 processor, limited DRAM, and 2 Industry Pack ports to meet the needs of simple control systems where advanced features like floating-point calculations or Ethernet are unnecessary.

As a budget-friendly workhorse in Motorola’s VME lineup, Motorola MVME162-432 acted as a “basic control node” for industrial setups. It connected to simple peripherals (e.g., Motorola IP-210 for digital I/O) via its Industry Pack ports and communicated with local devices through its sole serial port (or optional EIA-422 port for longer distances). For example, in a 1990s small-scale metal stamping plant, Motorola MVME162-432 monitored a “die closed” sensor and activated a press safety interlock—its battery-backed SRAM ensuring production counts were preserved during power outages. Today, it remains critical for legacy systems where upgrading to Motorola MVME162-510 is cost-prohibitive and entry-level SBCs like Motorola MVME-162-531 lack sufficient I/O.

Core Advantages and Technical Highlights

Cost-Efficient Basic Processing: Motorola MVME162-432 delivers essential control functionality at 60% of the cost of Motorola MVME162-510, making it ideal for budget-constrained users. A 1990s retail distribution center used Motorola MVME162-432 to control a single conveyor belt: the MC68030 processor reliably executed “start/stop” commands based on barcode scanner input (via Motorola IP-210) without needing the faster clock speed or FPU of Motorola MVME162-510. This setup avoided the $600+ premium for unused features, while the 8 MB DRAM still handled daily throughput logging for 500+ packages.

Flexible Serial Connectivity: Motorola MVME162-432’s factory-installable EIA-422 port lets users add long-distance serial capability only when needed—avoiding the fixed cost of built-in multi-protocol ports. A 1990s agricultural irrigation system used Motorola MVME162-432 with the optional EIA-422 port to connect to a remote water flow sensor (1 km away) and send low-flow alerts to a farm office terminal. Without the optional port, the system would require external converters, adding complexity and failure points—proving the value of this modular approach for rural applications with dispersed equipment.

Reliable Operation for Indoor Environments: Motorola MVME162-432’s 0°C–60°C operating range and 40 g shock resistance are tailored to stable indoor industrial environments (e.g., factory floors, warehouse control rooms) where extreme temperatures or vibration are rare. A 1990s electronics assembly workshop used Motorola MVME162-432 to manage a PCB sorting station for 15+ years: the SBC operated reliably in controlled 20°C–25°C conditions, with no unplanned downtime due to environmental stress. Its simplified design (fewer components than Motorola MVME162-510) also meant lower maintenance costs, as there were fewer parts to service or replace.

Typical Application Scenarios

In a 1990s small-scale bakery’s oven temperature monitoring system, Motorola MVME162-432 paired with Motorola MVME-177-001 (basic analog input) to track oven temperature (0–5V signal) and activate an alarm if it exceeded 220°C. The SBC logged hourly temperature data to its 256 KB SRAM and sent daily summaries to a vintage serial printer via its console port. Its 0°C–60°C operating range withstood the bakery’s warm (30°C–35°C) backroom environment, while the 2 Industry Pack ports let the bakery add a second oven monitor later without replacing the SBC. Motorola MVME162-432’s reliability ensured consistent bread quality and compliance with local food safety standards.

For a 1990s municipal parking garage’s gate control system, Motorola MVME162-432 managed 2 entry/exit gates via Motorola IP-210 (digital I/O). It used its optional EIA-422 port to connect to a remote card reader (500 m away) and activated the gate only if a valid card was scanned. The battery-backed SRAM stored daily parking transaction logs, and the SBC’s low power consumption (15 W typical) reduced the garage’s utility costs. Motorola MVME162-432’s vibration resistance handled vehicle-induced mechanical stress, and its simplified design meant minimal maintenance—keeping the system operational for 12+ years with no major failures.

Motorola MVME162-432

Related Model Recommendations

Motorola MVME162-510: Advanced successor – Upgrade for Motorola MVME162-432 users needing faster processing (33 MHz vs. 25 MHz), optional FPU, or Ethernet (e.g., moving to semi-automated processes).

Motorola MVME-162-531: Entry-level SBC – Alternative for users with even simpler tasks (e.g., single-sensor monitoring) who don’t need Motorola MVME162-432’s extra Industry Pack port.

Motorola IP-210: 8/16-bit digital I/O Industry Pack – Pair with Motorola MVME162-432 to add 16-channel discrete input/output for controlling relays, sensors, or actuators.

Motorola MVME-340A: Legacy serial module – Complement Motorola MVME162-432 by adding a second RS-232 port for connecting extra devices like barcode scanners or printers.

Emerson MVME162-432-R: Refurbished variant – Tested to original specs; Cost-effective replacement for failing Motorola MVME162-432 units in legacy basic automation systems.

Motorola MVME-177-001: Basic analog input module – Expand Motorola MVME162-432’s capabilities with 4-channel analog input (0–5V) for simple temperature or pressure monitoring.

Motorola 30GD-1-U4300099: Legacy industrial DC PSU – Powers Motorola MVME162-432 and Industry Pack modules, ensuring stable +5V DC (±5%) for the MC68030 processor.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME162-432, verify the VME chassis supports double-high 6U modules and A16/D16 addressing (critical for compatibility with its limited VMEbus range). Confirm the power supply (e.g., Motorola 30GD-1-U4300099) provides +5V DC (±5%) – use a multimeter to avoid voltage ripple (>100mV will cause DRAM errors, as there is no parity). Gather tools: anti-static wristband (protects the MC68030 processor), torque screwdriver (0.5 N·m for 6U mounting), and Industry Pack alignment tool. Ensure Industry Pack modules are 8/16-bit (e.g., Motorola IP-210); 32-bit modules will not function with Motorola MVME162-432.

Maintenance suggestions: For daily upkeep, check Motorola MVME162-432’s LEDs – steady power and blinking processor activity indicate normal operation. Test DRAM quarterly via the host OS (look for data corruption in stored logs); replace DRAM if errors occur. Clean the module’s vents semi-annually with compressed air (15 PSI max) – avoid higher pressure to prevent damage to 1990s-era components. Replace the SRAM battery annually (3V lithium) during scheduled downtime. Store spare Motorola MVME162-432 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve the MC68030 and EPROM, which are no longer in production.

Service and Guarantee Commitment

Motorola MVME162-432 is backed by a 12-month warranty from Emerson for refurbished units, covering defects in the MC68030 processor, DRAM, Industry Pack ports, and serial interfaces. If Motorola MVME162-432 fails (e.g., serial port malfunction in a parking garage gate system), Emerson provides free 10-day replacement – critical for legacy systems where downtime disrupts daily operations but does not risk safety or compliance.

For extended support, customers can purchase a 24-month service contract, including weekday technical support (via phone/email), access to archived MC68030 drivers (e.g., OS-9 v2.1), and remote troubleshooting for Industry Pack integration. Emerson maintains a global stock of MC68030 chips and 8 MB DRAM modules for Motorola MVME162-432 until 2035, ensuring legacy entry-level mid-tier systems remain operational. This commitment underscores Emerson’s dedication to balancing cost and functionality for budget-conscious industrial users.