Description

Detailed Parameter Table

| Parameter name | Parameter value |

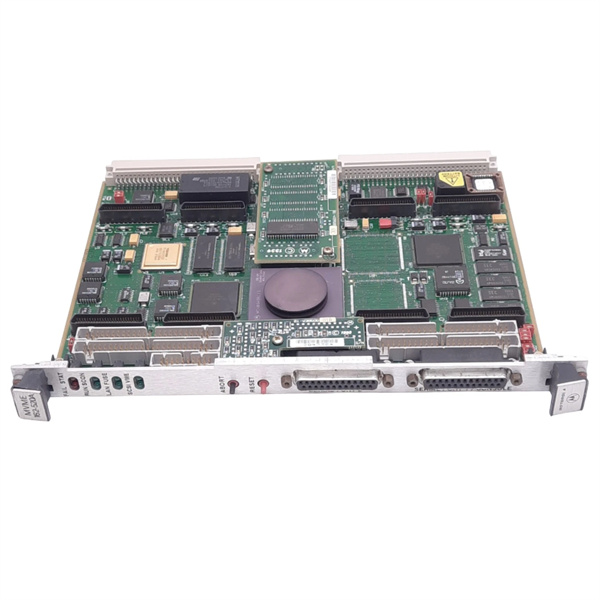

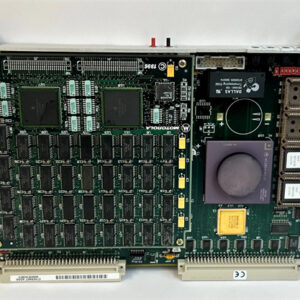

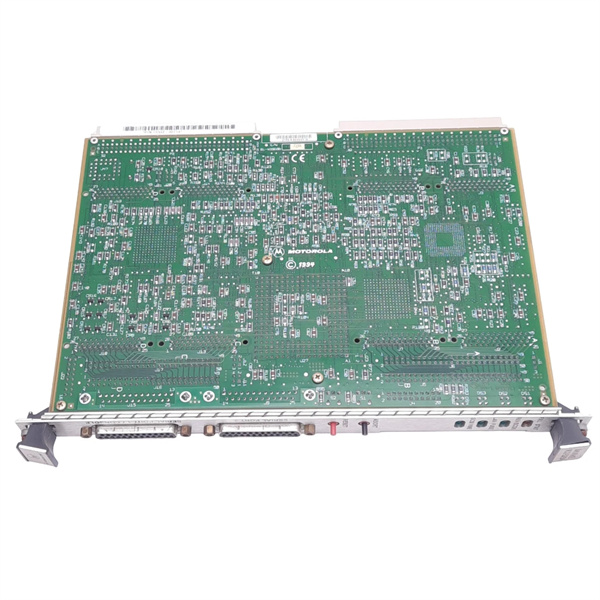

| Product model | Motorola MVME162-520A |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Mid-to-High Performance Industrial VMEbus Single-Board Computer (SBC) |

| Processor | Motorola PowerPC 750 RISC processor, 600 MHz (32-bit data/address bus, with 128 KB L2 cache) |

| Memory | 256 MB DDR SDRAM (expandable to 512 MB via DIMM slot); 8 MB Flash ROM (boot/OS storage, write-protected) |

| Communication Interfaces | 2x 10/100 Base-T Fast Ethernet (RJ45, TCP/IP/UDP); 2x RS-232/422/485 serial ports (DB-9, configurable); 1x 2-lane Serial RapidIO (1.25 Gbps/lane) |

| Storage Interfaces | Integrated IDE controller (supports 2.5″ HDD/SSD); 1x CompactFlash Slot (Type I/II, up to 64 GB); 1x USB 1.1 port (for debugging/external storage) |

| Expansion Slots | 1x 32-bit/66 MHz PMC (PCI Mezzanine Card) slot (full-height, compatible with analog I/O, serial expansion cards); 1x VMEbus P2 expansion connector |

| Environmental Requirements | Operating temp: -30°C to 65°C (-22°F to 149°F); Storage temp: -40°C to 85°C (-40°F to 185°F); Humidity: 5%–95% (non-condensing, 35°C dew point); Vibration: 10–1000 Hz, 1.5 g (rms); Shock: 70 g (peak, 1 ms) |

| Physical Size | 6U VMEbus form factor: 233.35 mm × 160.02 mm (9.19 in × 6.30 in); Weight: 520 g (1.15 lbs) |

| Power Consumption | Typical: 22 W (25°C, full load); Maximum: 28 W |

| Operating System Support | VxWorks 6.8+, QNX Neutrino 6.5+, Linux for PowerPC (kernel 3.10+); Motorola legacy RTOS |

| Diagnostic Features | Built-in Self-Test (BIST) for processor/memory/network; Single watchdog timer (1–60s, configurable); LED indicators (power, Ethernet, fault, PMC status); Local health monitoring via front-panel LEDs |

Motorola MVME162-520A

Product Introduction

The Motorola MVME162-520A is a mid-to-high performance industrial VMEbus Single-Board Computer (SBC) from Motorola (now integrated into Emerson’s portfolio), a key model in the MVME162 series—designed to balance processing power, expandability, and cost for mid-scale mission-critical automation. As a step below the flagship Motorola MVME162-523, the Motorola MVME162-520A targets applications that require more performance than mid-tier Motorola MVME-167-04B but don’t need the extreme ruggedness or 1 GB memory of the MVME162-523, such as real-time manufacturing control, regional energy monitoring, and railway signaling systems.

In automation architectures, the Motorola MVME162-520A acts as a “central processing node”: it collects data from 50–100 peripheral sensors (via modules like Motorola MVME-717 digital input or Motorola MVME-761-001 analog I/O), processes it using its 600 MHz PowerPC 750 processor, and sends synchronized control commands to actuators (e.g., conveyor motors, valves). Its Fast Ethernet and Serial RapidIO interfaces enable reliable data transmission to SCADA systems or local VMEbus modules, while the PMC slot supports customization for specialized tasks (e.g., adding analog I/O for temperature monitoring). This makes the Motorola MVME162-520A a versatile choice for industries like automotive manufacturing, mid-sized water treatment plants, and regional power distribution—where reliability and performance must align with budget constraints.

Core Advantages and Technical Highlights

Balanced Performance for Mid-Scale Automation: The Motorola MVME162-520A features a 600 MHz PowerPC 750 processor with 128 KB L2 cache and 256 MB DDR SDRAM (expandable to 512 MB)—delivering 2x the processing power of the Motorola MVME-167-04B (166 MHz) while avoiding the premium of the Motorola MVME162-523 (800 MHz). This enables it to handle 500+ concurrent sensor data streams (e.g., in automotive assembly line monitoring) and execute multi-variable PID control loops with latency <8 ms. For example, in a 4-axis robotic welding cell, the Motorola MVME162-520A processes 80+ data points/second (weld temperature, arm position) to maintain weld quality, outperforming lower-power SBCs without the cost of a flagship model.

Flexible Connectivity for Hybrid Networks: A key strength of the Motorola MVME162-520A is its 2x 10/100 Base-T Fast Ethernet ports and 2-lane Serial RapidIO (1.25 Gbps/lane). The Fast Ethernet ports support reliable communication with local SCADA/HMI systems (e.g., sending production logs to a factory MES), while Serial RapidIO enables low-latency links to nearby VMEbus modules (e.g., Motorola MVME-910-3 Ethernet gateways). This hybrid connectivity is ideal for facilities transitioning from legacy VMEbus systems to modern IP networks— the Motorola MVME162-520A acts as a bridge, reducing retrofitting costs by preserving existing I/O modules while enabling integration with new digital tools.

Rugged Design for Industrial Environments: Built to withstand tough operating conditions, the Motorola MVME162-520A operates in temperatures from -30°C to 65°C—suitable for unheated factory floors (e.g., metal stamping plants) and outdoor enclosures (e.g., solar farm inverters). It resists 1.5 g rms vibration (10–1000 Hz) and 70 g peak shock (1 ms), protecting components from mechanical stress in mobile applications like railway trackside control. The SBC uses industrial-grade components: wide-temperature DDR SDRAM (-30°C to 85°C) and corrosion-resistant VMEbus connectors, ensuring a mean time between failures (MTBF) exceeding 250,000 hours. Unlike commercial SBCs, it requires no additional cooling in most industrial cabinets, simplifying installation.

Cost-Effective Expandability via PMC Slot: The Motorola MVME162-520A includes a 32-bit/66 MHz PMC slot—enabling customization without overinvesting in fixed features. For example, adding a PMC analog I/O card (e.g., Motorola MVME-230) allows monitoring of 16 temperature sensors in a plastic extrusion machine; a PMC serial card adds 4 RS-485 ports for distributed pump controllers. This expandability means one Motorola MVME162-520A can adapt to multiple projects (e.g., switching from water treatment to HVAC control by swapping PMC cards), reducing inventory costs compared to application-specific controllers.

Typical Application Scenarios

In automotive assembly plants, the Motorola MVME162-520A controls a 6-station conveyor system for car body welding. It connects to 60+ proximity sensors (via Motorola MVME-717 modules) to track body position and 12 temperature sensors (via a PMC analog I/O card) to monitor weld guns. The SBC processes 500+ data points/second, adjusting conveyor speed and weld current in real-time to maintain production rates (60 cars/hour). Its Fast Ethernet port sends weld quality data to a central MES, while the CompactFlash slot stores backup recipes for different car models. The Motorola MVME162-520A’s -30°C to 65°C operating range withstands the plant’s unheated welding bays, ensuring 99.8% uptime.

For regional solar farm monitoring, the Motorola MVME162-520A manages 30+ solar inverters and 100+ irradiance sensors. It collects analog data (inverter output voltage, solar panel temperature) via Motorola MVME-761-001 modules, processing it to optimize power output (e.g., adjusting inverter settings for cloud cover). Its 2x Fast Ethernet ports enable redundant communication: one links to a local SCADA system, the other to a cloud platform for remote monitoring. The Motorola MVME162-520A’s rugged design resists vibration from wind and 70 g shock (from storm debris), while its 22 W typical power consumption fits within the farm’s solar-powered control cabinets.

In railway trackside signaling systems, the Motorola MVME162-520A monitors 40+ track circuits and 20 switch machines. It uses RS-485 serial ports to communicate with trackside sensors and Serial RapidIO to link to a nearby VMEbus-based interlocking controller. The SBC processes sensor data to detect train presence and control switch positions, with <8 ms latency to ensure safe signaling. Its -30°C operating range withstands winter temperatures, and the write-protected Flash ROM prevents firmware tampering. The Motorola MVME162-520A’s reliability is critical—downtime here could disrupt rail traffic, making its 250,000+ MTBF a key asset.

Motorola MVME162-520A

Related Model Recommendations

Motorola MVME162-523: Flagship upgrade of the Motorola MVME162-520A with 800 MHz processor, 512 MB expandable memory, and Gigabit Ethernet. Ideal for high-performance needs (e.g., aerospace testing) where the MVME162-520A’s 600 MHz is insufficient.

Motorola MVME-167-04B: Mid-tier alternative to the Motorola MVME162-520A with 166 MHz PowerPC 603e. Suitable for low-to-mid scale tasks (e.g., small water treatment plants) where budget is prioritized over performance.

Motorola MVME-230: PMC analog I/O card for the Motorola MVME162-520A. Adds 8 analog inputs/4 outputs, enabling temperature/pressure monitoring in manufacturing or energy applications.

Motorola MVME-717: Digital input module compatible with the Motorola MVME162-520A. Provides 32 isolated channels for connecting proximity sensors or limit switches in assembly lines.

Motorola MVME-050: Industrial power supply for the Motorola MVME162-520A. Delivers stable ±5V/±12V output (85–264 VAC input) to power the SBC and one PMC card, handling its 28 W max load.

Motorola MVME-910-3: Ethernet gateway module for the Motorola MVME162-520A. Adds 10/100 Base-TX Ethernet to legacy VMEbus modules, extending the SBC’s network reach.

Motorola MVME-712-11: Digital output module for the Motorola MVME162-520A. Offers 16 high-current (2 A) channels to control actuators (e.g., conveyor motors, valves) in industrial processes.

Motorola MVME-177-001: High-precision analog I/O module for the Motorola MVME162-520A. Provides 16-bit resolution (vs. 12-bit in MVME-761-001) for accurate sensor data in solar or railway applications.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME162-520A, verify the VMEbus chassis supports 6U modules and provides stable ±5V/±12V power (use a multimeter to confirm voltage tolerance within ±4% for optimal performance). Gather tools: anti-static wristband (to protect the 600 MHz processor and DDR SDRAM), torque screwdriver (0.45 N·m for chassis mounting), Fast Ethernet cable tester, and a laptop (for OS configuration via USB 1.1). If installing a PMC card, ensure it is full-height compatible—align with the SBC’s slot guides, press gently until seated, and secure with locking screws. Power off the chassis, clean the VME backplane connector with a dry brush to remove dust, then slide the Motorola MVME162-520A into the backplane until fully seated (check for bent pins).

Maintenance suggestions: For daily upkeep, inspect the Motorola MVME162-520A’s LEDs—steady green power, blinking Fast Ethernet, and solid PMC status LEDs indicate normal operation. A red fault LED signals issues (run BIST via the OS to diagnose memory/network faults). Clean the SBC’s air vents (if fan-cooled) monthly with compressed air (25 PSI max) to prevent overheating; for fanless variants, wipe the chassis with a lint-free cloth. Every 4 months, back up the IDE/CompactFlash data to a secure server and update the Flash ROM firmware (via Emerson’s portal) to address vulnerabilities. If the Motorola MVME162-520A experiences communication delays, check Serial RapidIO cable connections and verify Ethernet port settings (IP address, subnet mask). Store spare units in anti-static bags in a climate-controlled environment (-15°C–25°C, 35%–55% humidity).

Service and Guarantee Commitment

The Motorola MVME162-520A is backed by a 30-month factory warranty from Emerson, covering defects in materials and workmanship (e.g., processor failures, Ethernet port malfunctions, PMC slot issues). If a defect is identified during the warranty period, Emerson provides free 2-day replacement for in-stock units—minimizing downtime for mid-scale operations where extended outages impact productivity. For extended support, customers can purchase service contracts (up to 48 months) including 24/7 technical support, bi-annual on-site checks, and priority firmware updates.

Emerson maintains a global stock of critical components for the Motorola MVME162-520A (e.g., PowerPC 750 processors, DDR SDRAM modules) to support legacy users until 2038. Technical engineers specialize in MVME162 series SBCs, offering remote troubleshooting (via Ethernet) and on-site assistance for complex integration (e.g., PMC card setup). This commitment ensures the Motorola MVME162-520A delivers long-term value, whether powering new automotive assembly lines or upgrading legacy energy monitoring systems.