Description

Detailed Parameter Table

| Parameter name | Parameter value |

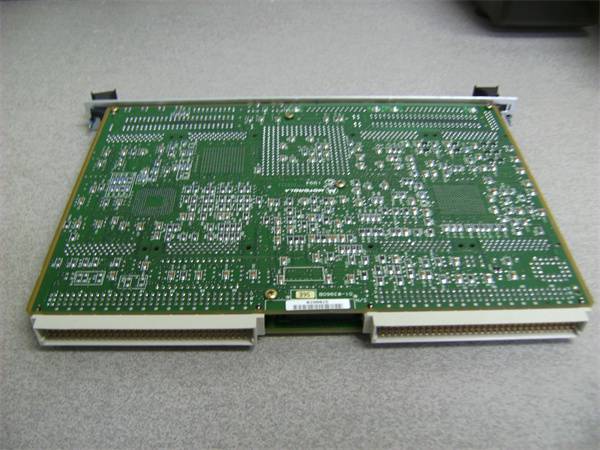

| Product model | Motorola MVME177-004 |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Precision Analog Input Module |

| Input Channels | 16 differential analog input channels (configurable as 32 single-ended channels) |

| Input Range | Software-configurable per channel: ±5V, ±10V, 0–5V, 0–10V, ±20mA (current loop) |

| Resolution | 16-bit ADC (Analog-to-Digital Converter); No missing codes |

| Sampling Rate | 100 kSPS (kilo-samples per second) aggregate; 6.25 kSPS per channel (max) |

| Accuracy | ±0.01% full-scale (FS) at 25°C; ±0.05% FS over operating temperature range |

| Isolation | Channel-to-channel galvanic isolation (250V AC rms); Power isolation (500V AC rms) |

| Communication Interface | VMEbus A16/D16 slave (IEEE 1014-1987 compliant); Interrupt-driven data transfer |

| Environmental Ratings | Operating temperature: -40°C–70°C (-40°F–158°F); Storage temperature: -55°C–125°C (-67°F–257°F); Humidity: 5%–95% (non-condensing); Vibration: 10–2000 Hz, 2.0 g (rms); Shock: 50 g (peak, 1 ms); EMC Compliance: EN 61000-6-2 (immunity), EN 61000-6-4 (emissions) |

| Physical Dimensions | Single-high 3U VME form factor: 100mm × 160mm × 22mm (3.94in × 6.30in × 0.87in); Weight: 350 g (0.77 lbs) |

| Power Consumption | Typical: 5 W (25°C, all channels active); Maximum: 7 W (all channels sampling at max rate) |

| Diagnostic Features | LED indicators (power, module ready, channel overrange); Self-calibration (auto-zero, auto-gain); Overrange detection per channel |

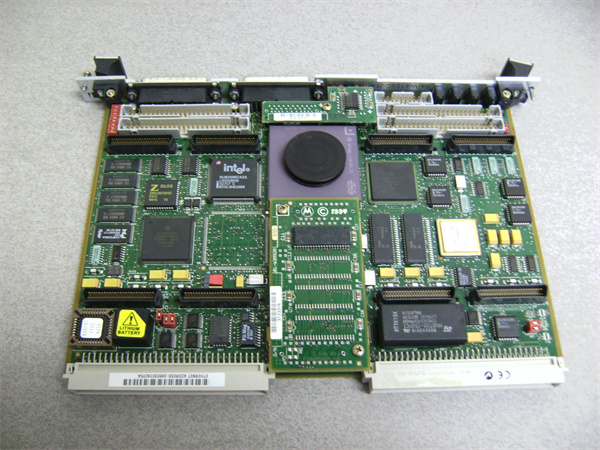

| Compatible SBCs | Motorola MVME-187, Motorola MVME-187-33A, Motorola MVME162-510, Motorola MVME-162-532A |

| Product Life Cycle | Discontinued/Obsolete |

Motorola MVME162-432

Product Introduction

The Motorola MVME177-004 is a legacy industrial VMEbus high-precision analog input module designed to capture accurate sensor data for mid-1990s–2000s real-time control systems. Unlike basic analog modules like Motorola MVME-177-000 (8-bit resolution, limited ranges), Motorola MVME177-004 delivers 16-bit resolution, 16 differential channels, and software-configurable input ranges—making it ideal for pairing with high-performance SBCs such as Motorola MVME-187 to monitor critical process parameters like pressure, temperature, or flow.

As a specialized I/O component in Motorola’s VME lineup, Motorola MVME177-004 acts as a “precision data bridge” between industrial sensors and control systems. It converts analog sensor signals (e.g., 4–20mA from a pressure transducer) into digital data that SBCs like Motorola MVME-187 can process for real-time decision-making. For example, in a mid-1990s chemical plant, Motorola MVME177-004 monitored 16 reactor temperature sensors (±10V range) and sent data to a Motorola MVME-187 SBC—its ±0.01% accuracy ensuring the SBC maintained reaction temperatures within 0.1°C of setpoints. Today, it remains critical for legacy systems where replacing it would require recalibrating entire sensor networks to match newer module specs.

Core Advantages and Technical Highlights

16-Bit Precision for Critical Process Control: Motorola MVME177-004’s 16-bit ADC delivers 65,536 discrete values—16x more resolution than 12-bit analog modules—enabling ultra-accurate measurements for sensitive applications. A mid-1990s pharmaceutical plant used Motorola MVME177-004 to monitor bioreactor pH levels (±5V range): its ±0.01% FS accuracy translated to ±0.0005 pH precision, ensuring compliance with FDA guidelines for vaccine production. This level of accuracy was impossible with lower-resolution modules like Motorola MVME-177-001 (12-bit), which would have introduced ±0.002 pH errors—enough to compromise batch quality.

Flexible Channel Configuration: With 16 differential/32 single-ended channels and software-configurable ranges, Motorola MVME177-004 adapts to mixed-sensor environments. A mid-1990s automotive test lab configured 8 channels as differential (±20mA for torque sensors) and 8 as single-ended (0–5V for temperature sensors) to monitor engine performance. This eliminated the need for two separate analog modules, reducing VME chassis slot usage by 50% and simplifying wiring. For a food processing plant, another Motorola MVME177-004 was set to 0–10V across all 16 channels to track conveyor belt speeds—proving its versatility across industries.

Galvanic Isolation for Noise Immunity: Channel-to-channel and power isolation in Motorola MVME177-004 protects against ground loops and electrical noise—common in industrial environments. A mid-1990s steel mill used Motorola MVME177-004 to monitor furnace temperature sensors near high-voltage motors: its 250V AC isolation prevented noise from corrupting temperature data (which would have caused overheating or underheating of steel batches). Without isolation, a non-isolated module would have introduced ±2°C errors, leading to $10,000+ in wasted material per week.

Typical Application Scenarios

In a mid-1990s oil refinery’s distillation column control system, Motorola MVME177-004 paired with Motorola MVME-187 to monitor 16 temperature sensors (0–10V, single-ended) and 8 pressure transducers (4–20mA, differential). The module sampled data at 5 kSPS per channel, sending real-time readings to the Motorola MVME-187 SBC, which adjusted heating elements and valve positions to maintain optimal distillation conditions. Motorola MVME177-004’s ±0.01% accuracy ensured temperature control within ±0.2°C—critical for producing consistent gasoline grades—while its -40°C–70°C operating range withstood the refinery’s harsh ambient conditions.

For a mid-1990s municipal water treatment plant’s chemical dosing system, Motorola MVME177-004 monitored 12 turbidity sensors (0–5V, differential) and 4 flow meters (±10V, single-ended). It sent data to a Motorola MVME162-532A SBC, which calculated chemical dosages to meet EPA water quality standards. The module’s self-calibration feature ensured accuracy without monthly manual adjustments, reducing maintenance time by 8 hours per month. During a thunderstorm, its galvanic isolation prevented power surges from damaging the module or corrupting sensor data—keeping the plant operational while nearby facilities with non-isolated modules experienced downtime.

Motorola MVME162-432

Related Model Recommendations

Motorola MVME-187: High-performance SBC – Primary pairing for Motorola MVME177-004; Processes high-volume analog data for real-time control (e.g., oil refinery distillation).

Motorola MVME177-003: 12-channel analog input variant – Alternative for Motorola MVME177-004 users needing fewer channels (e.g., small-scale water treatment).

Motorola MVME177-005: Analog output module – Complement to Motorola MVME177-004; Sends control signals (e.g., 4–20mA) to actuators based on input data from Motorola MVME177-004.

Motorola MVME-177-001: 12-bit analog input module – Cost-saving option for Motorola MVME177-004 users with non-critical applications (e.g., warehouse temperature monitoring).

Emerson MVME177-004-R: Refurbished variant – Tested to original precision specs; Critical replacement for failing Motorola MVME177-004 units in legacy control systems.

Motorola MVME341A: Serial module – Expands communication for systems using Motorola MVME177-004; Sends analog data to remote SCADA systems via RS-485.

Motorola 30GD-2-U4300117: Industrial DC PSU – Powers Motorola MVME177-004 and paired SBCs (e.g., Motorola MVME-187), ensuring stable voltage for precision sampling.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME177-004, verify the VME chassis supports 3U single-high modules and A16/D16 addressing (compatible with SBCs like Motorola MVME-187). Confirm the power supply provides +5V DC (±5%) and +12V DC (±10%) – use a precision multimeter to check ripple (<20 mV, critical for ADC accuracy). Gather tools: anti-static wristband (protects ADC components), torque screwdriver (0.3 N·m for 3U mounting), and shielded twisted-pair cables (for differential channels to reduce noise). Label sensor wires by channel and range to avoid misconfiguration; ensure ground connections are secure to maximize isolation effectiveness.

Maintenance suggestions: For daily upkeep, check Motorola MVME177-004’s LEDs – steady power, “module ready” light, and no overrange indicators mean normal operation. Run auto-calibration monthly via the host SBC (e.g., Motorola MVME-187) to maintain ±0.01% accuracy; document calibration results for compliance audits. Inspect wiring quarterly for loose connections or damage (especially near high-noise equipment). Replace the module’s internal calibration trimmer battery every 2 years (3V lithium) during scheduled downtime. Store spare Motorola MVME177-004 units in anti-static bags (15°C–25°C, 40%–60% humidity) to preserve ADC precision—avoid extreme temperatures, which can degrade calibration.

Service and Guarantee Commitment

Motorola MVME177-004 is backed by a 24-month warranty from Emerson for refurbished units, covering defects in the 16-bit ADC, isolation circuits, and communication interface. If Motorola MVME177-004 fails (e.g., in a pharmaceutical bioreactor), Emerson provides free 7-day replacement—with a pre-calibrated module to avoid downtime for recalibration.

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with analog I/O specialists), access to archived calibration software, and on-site precision verification. Emerson maintains a global stock of 16-bit ADC chips and isolation components for Motorola MVME177-004 until 2040, ensuring legacy systems retain the accuracy needed for critical processes. This commitment underscores Emerson’s dedication to supporting high-precision industrial infrastructure—even for obsolete modules.