Description

Detailed Parameter Table

| Parameter name | Parameter value |

| Product model | Motorola MVME320B – 1 |

| Manufacturer | Motorola |

| Product category | VMEbus Intelligent Winchester / Floppy Disk Controller Module; Single – slot VME module |

| Microprocessor | PowerPC™ series (not specified in extreme detail, but part of the module’s processing architecture) |

| Input Power | 89 – 280 VAC; Input voltage range: 35 … 269 V AC, 48 … 67 Hz |

| Memory | 295 KB in total; 280 KB application runtime; 630 KB non – volatile memory (application objects plus text and bitmaps) |

| Communication | Remote I/O (RIO); RS212 (printer); Communication cable: MVME series |

| Shipping Weight | 3.8 lbs (about 1.72 kg); Unit weight: 1.8 kg |

| Shipping Dimensions | 380 x 350 x 20mm |

| Product Life Cycle Status | Discontinued / Obsolete |

| Function Keys | 12 function keys (F1…F10) |

| Touchscreen | Touch cells: 180; Actuation: 1.5 million presses |

| Resolution | 120 * 350 |

| Display Area | 125 x 55 mm (4.54 x 3.4 in.) |

| Display Type | Green |

| Part Numbers | 01 – W3483B, 01 – W3484B 02D, 01 – W3484B 02C, 01 – W3483B 02B |

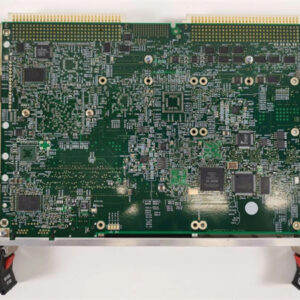

Motorola MVME320B-1

Product Introduction

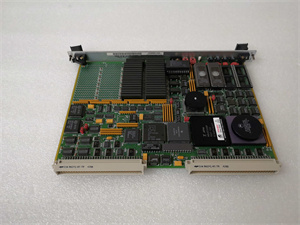

The Motorola MVME320B – 1 is a VMEbus Intelligent Winchester / Floppy Disk Controller Module, crafted as a single – slot VME module. It is engineered to play a crucial role in industrial and embedded systems, mainly facilitating data storage and retrieval operations related to Winchester (hard disk) and floppy disk drives. Unlike some other modules that may focus on general – purpose computing or extensive I/O control, the MVME320B – 1 has a specialized function in disk drive management within the VMEbus ecosystem.

In industrial control systems, the MVME320B – 1 can be used to manage data storage for a manufacturing plant’s production control system. It can store historical production data, such as production volumes over time, machine utilization rates, and quality control records. In a factory where large amounts of data need to be stored and retrieved for process optimization and reporting, the MVME320B – 1 can interface with Winchester and floppy disk drives to ensure data integrity and efficient access. For example, it can be used to archive data from production line sensors for long – term analysis, or to load software and configuration files onto the production control system from floppy disks during system setup or maintenance.

Core Advantages and Technical Highlights

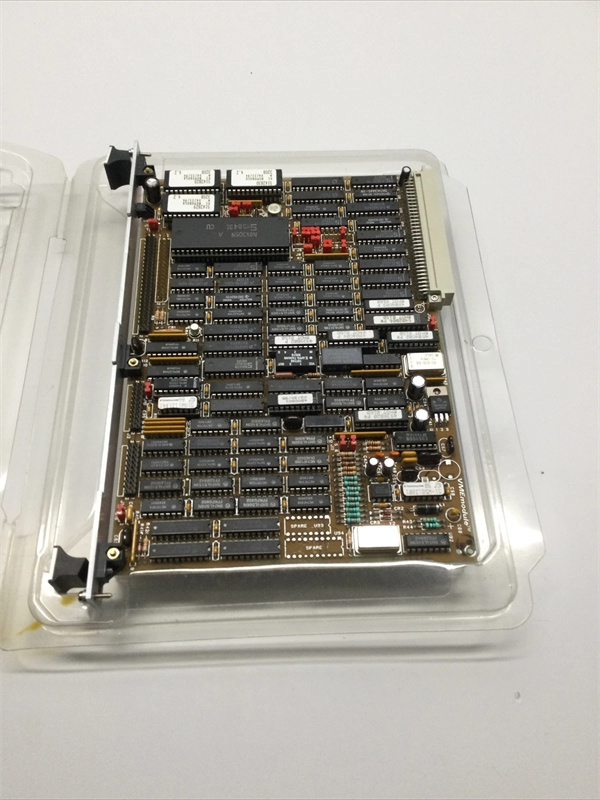

PowerPC – based Processing for Disk Operations: With a PowerPC™ series microprocessor at its core, the MVME320B – 1 is well – equipped to handle the complex data transfer and control operations associated with disk drives. PowerPC processors are known for their high – performance and reliability in industrial and embedded applications. This enables the module to manage data read and write operations to Winchester and floppy disk drives efficiently. In a data – intensive industrial application, such as a large – scale data – logging system in a chemical plant, the PowerPC processor can ensure that data from multiple sensors is quickly and accurately written to the hard disk, and retrieved when needed for analysis or reporting.

Adequate Memory Configuration: The module comes with a total of 295 KB of memory, including 280 KB of application runtime memory and 630 KB of non – volatile memory. The non – volatile memory is particularly important as it preserves application – related objects, text, and bitmaps. This ensures that even during power outages or system resets, essential data and settings related to disk drive management are retained. In a power generation facility, the non – volatile memory can store historical data about power generation levels, equipment performance, and maintenance schedules that are stored on the hard disk. This data can be retrieved during system startups or for long – term performance evaluations.

Reliable Disk Drive Connectivity: The MVME320B – 1 is designed to interface with ST506 Winchester and/or floppy disk drives, providing high – performance data channels between system memory and these storage devices. It can support up to two Winchester and two floppy disk drives or four floppy disk drives. The unit also features a fail – inform LED and three interface connections on the front panel. This setup allows for easy monitoring of the module’s status and convenient connection to external devices. In a research laboratory’s data storage system, the multiple drive support and front – panel interfaces make it easy for researchers to connect and manage different types of storage media for their experimental data.

Typical Application Scenarios

In industrial automation, the Motorola MVME320B – 1 can be used in production line data – logging systems. For instance, in an automotive manufacturing plant, it can store data from various sensors along the production line, such as torque sensors on assembly robots, temperature sensors on painting equipment, and quality control sensors for product inspection. This data can be retrieved later for process optimization, quality control analysis, and production reporting.

In a power generation and distribution infrastructure, the MVME320B – 1 can be used to manage data storage for power grid monitoring systems. It can store historical data about power generation levels, grid voltage and frequency measurements, equipment status information, and maintenance schedules. This data is crucial for analyzing the performance of the power grid over time, predicting equipment failures, and planning maintenance activities.

For small – to – medium – sized enterprise (SME) data storage in industries like textiles or food processing, the MVME320B – 1 can be used as a local data storage solution. It can store company – specific data such as production records, inventory information, and customer data. In a textile mill, for example, it can store data about fabric production volumes, raw material usage, and quality control test results. This data can be accessed by different departments within the company for decision – making and process improvement.

Motorola MVME320B-1

Related Model Recommendations

Motorola MVME – 327A: While the MVME320B – 1 focuses on disk drive control, the MVME – 327A is a single – slot hot swappable CompactPCI board with a PowerPC™ series microprocessor and user – interaction features like a touchscreen and function keys. In some industrial systems, the MVME320B – 1 can be used for data storage management, and the MVME – 327A can be used for local control and monitoring. In a factory production line, the MVME320B – 1 can store production data on hard disks, and the MVME – 327A can display this data and allow operators to interact with the production control system.

Other VME – compatible Disk Controller Modules: There are other VME – compatible disk controller modules available in the market. These may offer different form factors, support for different types of disk drives, or additional features such as higher data transfer rates or more advanced error – handling capabilities. For example, if an application requires support for modern high – capacity hard disk drives or advanced RAID configurations, other modules might be more suitable. However, the MVME320B – 1’s established reputation in legacy VME – based systems makes it a reliable choice for existing installations.

General – purpose Storage Controllers with VME Interface Adapters: In some cases, general – purpose storage controllers with VME interface adapters can be used as substitutes. These can offer more flexibility in terms of storage device compatibility and configuration options. But they might require more complex integration and configuration compared to the dedicated MVME320B – 1.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the Motorola MVME320B – 1, ensure that the VMEbus chassis has an available single – slot and is compatible with the MVME320B – 1’s form factor. Check the power supply to ensure it can provide the required 89 – 280 VAC (or within the 35 – 269 V AC, 48 – 67 Hz range). Use an anti – static wristband to protect the module from electrostatic discharge during handling. Gather tools such as a screwdriver for chassis mounting. Also, make sure that the Winchester and floppy disk drives that the MVME320B – 1 will interface with are properly configured and ready for connection.

Commissioning: After installation, power on the system. Use a compatible programming device or software to configure the MVME320B – 1. This may involve setting up disk drive parameters, initializing the memory, and loading the necessary disk – management software. Test the connection to the disk drives by performing simple read and write operations. Check the module’s status LEDs (such as the fail – inform LED) to ensure proper operation.

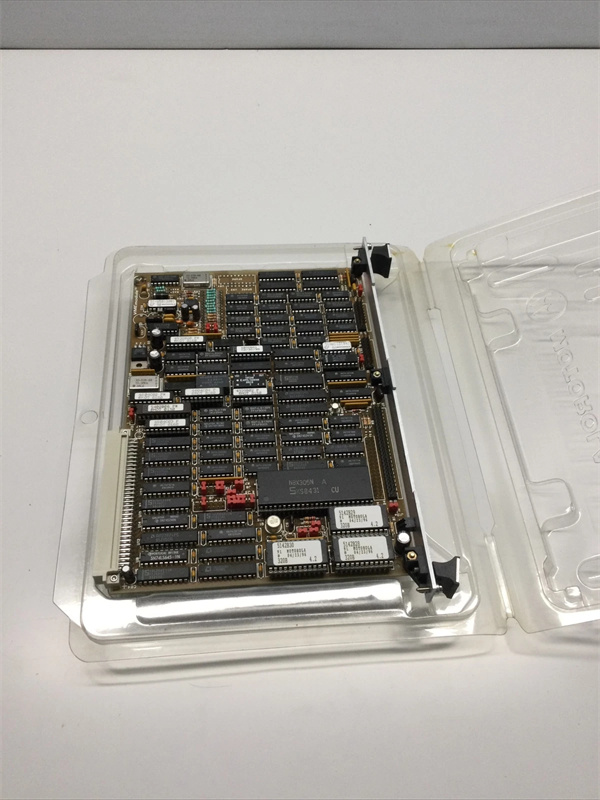

Maintenance suggestions: Regularly check the system logs for any error messages related to the MVME320B – 1’s disk drive operations. Monitor the performance of the disk drives over time, looking for signs of slow data transfer, disk errors, or other issues. Since it is a discontinued product, it is advisable to have spare modules in stock in case of failure. Store spare modules in an anti – static environment. If there are any issues with disk drive connectivity or data transfer, check the cables, the disk drive settings, and the MVME320B – 1’s configuration settings.

Service and Guarantee Commitment

As a discontinued product, the standard factory warranty is no longer applicable. However, some third – party service providers may offer repair services for the Motorola MVME320B – 1. These providers may have access to spare parts and the technical expertise to fix common issues such as disk controller failures, memory problems, or interface malfunctions.

Users are recommended to search for specialized legacy system support companies. These companies often maintain archives of technical documentation for discontinued products like the MVME320B – 1. They can provide valuable information on troubleshooting, repair procedures, and may even offer limited – time support contracts for critical applications. Although the MVME320B – 1 is discontinued, with proper support, it can still be used in legacy VME – based systems for a certain period, helping users avoid the high cost of a full – scale system replacement.