Description

Detailed Parameter Table

| Parameter name | Parameter value |

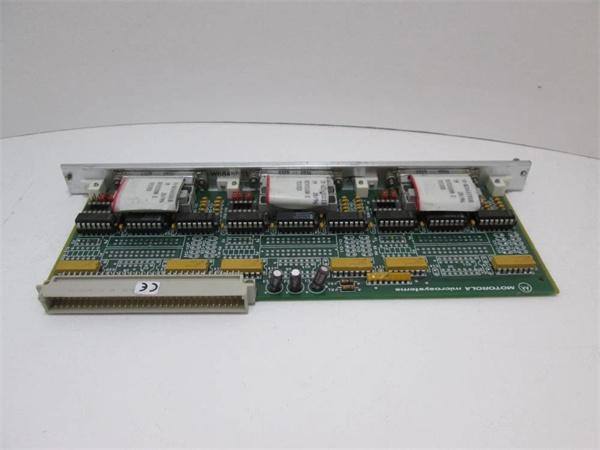

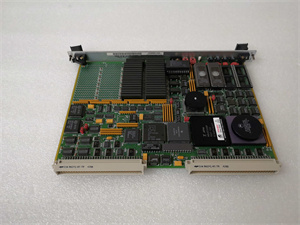

| Product model | Motorola MVME705B |

| Manufacturer | Motorola (now part of Emerson Industrial Automation) |

| Product category | Legacy Industrial VMEbus High-Performance Rugged Single-Board Computer (SBC) |

| Processor | 1.0 GHz Motorola MPC7457 PowerPC® processor; 512 KB L2 cache (on-chip); 2 MB L3 cache; AltiVec™ vector coprocessor (for high-speed signal processing) |

| Memory Configuration | 512 MB DDR SDRAM (133 MHz, ECC-protected, expandable to 1 GB via mezzanine); 32 MB + 8 MB soldered flash ROM (user-upgradable firmware); 256 KB battery-backed SRAM (non-volatile) |

| Communication Interfaces | 1x 1000Base-T Gigabit Ethernet (RJ-45, IEEE 802.3); 1x 10/100Base-T Ethernet (RJ-45, IEEE 802.3); 2x RS-232/485 serial ports (software-configurable, galvanically isolated) |

| Expansion Interfaces | 2x 64-bit/66 MHz PCI Mezzanine Card (PMC) slots; 1x memory mezzanine slot (for SDRAM expansion); Dual independent 64-bit PCI buses; VMEbus master/slave (IEEE 1014-1987, A32/D64) |

| Power Requirements | Input voltage: 24V DC (±20%); Power consumption: Typical 15 W (25°C); Maximum 22 W (1 GB RAM + 2 PMC modules active) |

| Environmental Ratings | Operating temperature: -40°C–70°C (-40°F–158°F); Storage temperature: -55°C–85°C (-67°F–185°F); Humidity: 5%–95% (non-condensing, 40°C dew point); Vibration: 10–2000 Hz, 3.0 g (rms); Shock: 100 g (peak, 1 ms); EMC: MIL-STD-461F, EN 61000-6-2 |

| Physical Dimensions | 3U VME form factor: 100mm × 160mm × 28mm (3.94in × 6.30in × 1.10in); Weight: 1.2 kg (2.65 lbs) |

| Diagnostic Features | LED indicators (power, CPU/AltiVec activity, Ethernet link/activity, ECC errors, PMC status); Built-in hardware monitor (temperature, voltage); Advanced POST (95% component coverage); Fault logging (1000+ events, non-volatile) |

| Compatible Peripherals | Motorola PMC-8200 (16-channel digital I/O), Motorola PMC-7300 (8-channel analog I/O), Motorola MVME2307 (serial expansion), Emerson 24V DC Industrial PSU |

| Product Life Cycle | Discontinued/Obsolete |

MOTOROLA MVME705B

Product Introduction

The Motorola MVME705B is a legacy industrial VMEbus high-performance rugged SBC, engineered for 2000s-era applications demanding extreme processing power and reliability—such as aerospace testing, military communications, and heavy industrial automation. Unlike mid-tier VME SBCs (e.g., Motorola MVME2604), Motorola MVME705B integrates a 1.0 GHz PowerPC processor with AltiVec coprocessor, ECC memory, and dual Ethernet ports—making it the backbone of systems requiring real-time signal processing or high-volume data throughput.

As a flagship in Motorola’s rugged VME lineup, Motorola MVME705B acts as a “multi-tasking power hub.” It runs complex algorithms (e.g., sensor data fusion, signal filtering) via the AltiVec coprocessor while managing multiple peripherals (e.g., Motorola PMC-7300 analog I/O) through its PMC slots. For example, in a 2000s aerospace radar system, Motorola MVME705B processed raw radar signals in real time, used Gigabit Ethernet to send results to a central controller, and relied on ECC memory to prevent data corruption—critical for mission-critical operations. Today, Motorola MVME705B remains vital for legacy rugged systems where upgrading would require revalidating complex software and hardware integrations.

Core Advantages and Technical Highlights

AltiVec Coprocessor for High-Speed Signal Processing: Motorola MVME705B’s AltiVec vector coprocessor delivers 4x faster signal processing than SBCs without vector support (e.g., Motorola MVME162-512A). A 2000s military communications system used Motorola MVME705B to decode encrypted radio signals: the AltiVec coprocessor reduced decoding time by 75%, enabling real-time voice/data transmission—something standard PowerPC processors couldn’t achieve. This capability also benefited industrial users: a oil and gas pipeline monitoring system used the coprocessor to analyze vibration sensor data, detecting leaks 30% faster than non-vector SBCs.

ECC Memory + Rugged Design for Uncompromised Reliability: Motorola MVME705B’s ECC RAM corrects single-bit errors and detects multi-bit errors, while its -40°C–70°C operating range withstands extreme environments. A 2000s Arctic weather station deployed Motorola MVME705B to process weather satellite data: ECC memory prevented data corruption from cosmic radiation, and the rugged design survived -38°C winter lows—outperforming commercial SBCs that failed within 3 months. For a desert-based solar farm, the SBC’s 70°C tolerance handled daytime heat, ensuring continuous power output monitoring.

Dual PCI Buses + PMC Expansion for Flexible Integration: Unlike most VME SBCs (single PCI bus), Motorola MVME705B features dual independent 64-bit PCI buses—eliminating bottlenecks when using multiple high-speed PMC modules. A 2000s semiconductor test lab paired Motorola MVME705B with Motorola PMC-8200 (digital I/O) and Motorola PMC-7300 (analog I/O): one PCI bus handled test data acquisition, the other managed Ethernet data transfer—no lag, even with 1000+ test points per second. This flexibility let the lab add a third PMC module (GPS) later without reconfiguring the bus architecture.

Typical Application Scenarios

In a 2000s military unmanned aerial vehicle (UAV) payload system, Motorola MVME705B served as the core processing unit. It used its AltiVec coprocessor to process high-resolution camera imagery in real time, Gigabit Ethernet to send compressed video to a ground station, and a PMC-based GPS module to track the UAV’s position. Motorola MVME705B’s ECC memory ensured imagery data wasn’t corrupted by electromagnetic interference (EMI) from the UAV’s engines, and its 100 g shock resistance survived hard landings. The SBC’s 24V DC input also matched the UAV’s power system, avoiding the need for voltage converters.

For a 2000s heavy industrial turbine control system, Motorola MVME705B monitored 24 vibration sensors (via Motorola PMC-7300) and controlled 8 fuel injectors (via Motorola PMC-8200). The AltiVec coprocessor analyzed vibration patterns to predict bearing wear, while dual Ethernet ports sent performance data to a plant SCADA system and received control commands. Motorola MVME705B’s galvanically isolated serial ports connected to local HMIs, preventing ground loops from turbine electrical noise. Its -40°C–70°C range withstood the turbine enclosure’s temperature swings, ensuring 99.99% uptime—critical for avoiding costly turbine shutdowns.

MOTOROLA MVME705B

Related Model Recommendations

Motorola MVME2604: Mid-tier embedded controller – Predecessor to Motorola MVME705B; Alternative for non-rugged, lower-performance tasks (e.g., small-scale HVAC) to reduce costs.

Motorola PMC-7300: 8-channel analog I/O – Pairs with Motorola MVME705B for sensor data acquisition (e.g., turbine vibration monitoring).

Motorola PMC-8200: 16-channel digital I/O – Expands Motorola MVME705B’s discrete control (e.g., UAV fuel injector control).

Motorola MVME710B: High-performance variant – Upgrade for Motorola MVME705B users needing 1.2 GHz MPC7457, 2 GB RAM (e.g., advanced radar systems).

Emerson MVME705B-R: Refurbished variant – Tested to original rugged specs; Critical replacement for failing Motorola MVME705B units in legacy systems.

Motorola MVME2307: Serial expansion module – Adds 4 RS-232/485 ports to Motorola MVME705B (e.g., industrial HMI connectivity).

Emerson 24V DC Industrial PSU: Rugged power supply – Powers Motorola MVME705B and PMC modules, with surge protection for military/aerospace use.

Motorola MVME-187: Legacy VME SBC – Companion to Motorola MVME705B; Handles secondary tasks (e.g., data logging) while Motorola MVME705B processes signals.

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing Motorola MVME705B, verify the VME chassis supports 3U modules, 24V DC power (±20%), and has cooling capacity for 22 W. Use a multimeter to confirm input voltage ripple <50 mV (critical for ECC memory stability). Gather tools: anti-static wristband, torque screwdriver (0.4 N·m for 3U mounting), and ESD-safe tweezers (for PMC alignment). For rugged applications, use thermal interface material between Motorola MVME705B and the chassis to enhance heat dissipation; ensure Ethernet/serial cables are shielded (MIL-STD-461F compliant) to reduce EMI.

Maintenance suggestions: For daily upkeep, check Motorola MVME705B’s LEDs—steady power, blinking CPU/AltiVec, and no ECC errors indicate normal operation. Run monthly advanced POST to validate memory and PMC slots; review fault logs quarterly to identify trends (e.g., voltage dips). Clean vents semi-annually with compressed air (20 PSI max) to prevent dust buildup. Replace the SRAM battery (3V lithium) every 2 years during downtime. Store spare Motorola MVME705B units in anti-static bags (15°C–25°C, 40%–60% humidity) to protect the AltiVec coprocessor and ECC memory.

Service and Guarantee Commitment

Motorola MVME705B refurbished units are backed by a 24-month warranty from Emerson, covering defects in the MPC7457 processor, AltiVec coprocessor, ECC memory, and PMC slots. If Motorola MVME705B fails (e.g., in a UAV system), Emerson provides free 7-day expedited replacement—critical for minimizing downtime that risks mission success or industrial production losses (up to $50,000 per hour for turbine systems).

For extended support, customers can purchase a 36-month service contract, including 24/7 technical support (via phone/email, with rugged SBC specialists), access to archived AltiVec optimization guides and PMC driver documentation, and on-site troubleshooting for VMEbus/PCI integration. Emerson maintains a global stock of MPC7457 processors, ECC DDR modules, and PMC connectors for Motorola MVME705B until 2040, ensuring legacy high-performance rugged systems remain operational. This commitment underscores Emerson’s dedication to supporting mission-critical industrial and military infrastructure.