Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | Motorola VME172PA-652SE |

| Manufacturer | Motorola (now part of Emerson’s industrial automation portfolio) |

| Product Category | VMEbus Enhanced Analog Input/Output (I/O) Module (precision signal acquisition & control) |

| Input Channel Configuration | 16 differential analog input channels (software-configurable for single-ended use); 24-bit ADC resolution |

| Output Channel Configuration | 8 analog output channels; 16-bit DAC resolution; voltage/current selectable per channel |

| Input Signal Range | ±10 VDC, ±5 VDC, ±2.5 VDC, ±1 VDC, 0–10 VDC, 0–5 VDC (software-selectable per channel) |

| Output Signal Range | Voltage: ±10 VDC, ±5 VDC, 0–10 VDC, 0–5 VDC; Current: 4–20 mA, 0–20 mA (software-selectable per channel) |

| Sampling Rate (Inputs) | Up to 500 kSPS (aggregate); 31.25 kSPS per channel (sequential sampling); 100 kSPS per channel (burst mode) |

| Update Rate (Outputs) | Up to 50 kSPS per channel (simultaneous updates supported) |

| Bus Standard | VMEbus (PICMG VME 3.0 compliant) – 32/64-bit address/data bus; master/slave dual-mode |

| Physical Dimensions | Standard 6U VME form factor (233.4 mm × 160 mm × 16 mm; L×W×H) – fits standard VME chassis slots |

| Power Requirements | +5 VDC (2.0 A typical, 3.0 A maximum); +12 VDC (0.8 A typical); -12 VDC (0.6 A typical); passive heat dissipation (heatsink-based) |

| Signal Isolation | Channel-to-channel isolation (1000 Vrms); module-to-bus isolation (2000 Vrms); galvanic isolation for inputs/outputs |

| Operating Temperature Range | -40°C – 70°C (-40°F – 158°F) (extended industrial temperature grade) |

| Product Status | Obsolete (discontinued by manufacturer; supported via aftermarket/refurbished services) |

| Compliance Standards | VMEbus 3.0; IEEE 1284 (optional parallel interface); FCC Class A (EMI); CE Mark; RoHS; IEC 61000-6-2/-4 (industrial EMC immunity/susceptibility) |

| On-Board Features | Programmable gain (1x, 2x, 4x, 8x, 16x, 32x); built-in self-test (BIST) for ADC/DAC validation; temperature-compensated calibration; overcurrent protection for outputs |

| Compatibility | Optimized for Motorola VME SBCs (Motorola MVME5500, Motorola MVME172-263/260); works with memory modules (Motorola MVME147S-1), power modules (Motorola FAB 0340-1049), and communication modules (Motorola MVME712/M) |

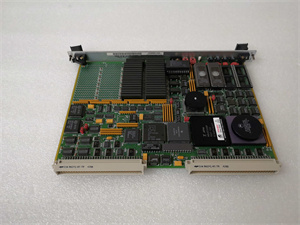

MOTOROLA VME172PA-652SE

Product Introduction

The Motorola VME172PA-652SE is a high-performance VMEbus analog I/O module, engineered to deliver precision signal acquisition and control for mission-critical industrial automation systems. As a 6U VME form factor device, it stands out from standard analog modules (like the Motorola MVME162PA-344E) with its 24-bit ADC (inputs) and 16-bit DAC (outputs), making it ideal for applications where nanoscale signal accuracy and robust noise immunity are non-negotiable.

A defining strength of the Motorola VME172PA-652SE is its seamless integration with the broader Motorola VME ecosystem. When paired with a powerful SBC like the Motorola MVME5500, it leverages the VMEbus’s 64-bit data path to transmit high-volume, high-precision analog data—essential for tasks like real-time process control (e.g., regulating chemical reactions via 4–20 mA output signals) or high-resolution sensor data logging (e.g., capturing microvolt-level temperature fluctuations). It draws stable power from modules like the Motorola FAB 0340-1049, while its extended temperature range (-40°C–70°C) ensures reliability in extreme environments—from arctic oil pipelines to desert-based solar farms.

Whether deployed in semiconductor manufacturing, aerospace test benches, or medical device calibration systems, the Motorola VME172PA-652SE acts as the “precision control backbone” of VME setups. Its temperature-compensated calibration and galvanic isolation minimize drift and noise, while the built-in self-test (BIST) simplifies maintenance—ensuring long-term accuracy that lower-grade modules cannot match. These features make it an indispensable upgrade for legacy systems requiring enhanced analog I/O capabilities.

Core Advantages and Technical Highlights

24-Bit ADC with Industry-Leading Precision

The Motorola VME172PA-652SE’s 24-bit ADC delivers 0.000015% full-scale accuracy—over 100x more precise than 16-bit modules and 400x more precise than 12-bit alternatives like the Motorola MVME162-533A. This level of precision is critical for applications like semiconductor wafer etching, where measuring 1 µV voltage variations in a 10 V signal (0.00001% of full scale) is required to maintain nanometer-scale manufacturing tolerances. The module’s programmable gain (up to 32x) further amplifies weak signals (e.g., 100 nV from a strain gauge), allowing it to detect anomalies that would go unnoticed by lower-precision modules. For example, in aerospace engine testing, the Motorola VME172PA-652SE can measure 5 µV fluctuations in fuel pressure—enabling engineers to identify early signs of pump wear before catastrophic failure.

Dual-Mode Outputs (Voltage/Current) for Versatile Control

Unlike single-mode analog output modules, the Motorola VME172PA-652SE’s 8 output channels support both voltage (±10 VDC, 0–10 VDC) and current (4–20 mA, 0–20 mA) signals—eliminating the need for separate voltage and current modules. This versatility adapts to diverse industrial actuators: 4–20 mA current outputs drive long-distance valves (common in oil refineries, where signal loss over 1000+ meter cables is minimized), while ±10 VDC voltage outputs control precision pumps in pharmaceutical manufacturing (where low current consumption is critical). For instance, in a water treatment plant, 4 channels can be set to 4–20 mA (controlling large chemical dosing pumps) and 4 channels to 0–5 VDC (regulating small solenoid valves)—all via software configuration, no hardware modifications needed.

Ultra-High Isolation for Extreme Noise Immunity

With 1000 Vrms channel-to-channel isolation and 2000 Vrms module-to-bus isolation (double the isolation of the Motorola MVME162PA-344E), the Motorola VME172PA-652SE eliminates ground loops and cross-talk in high-voltage industrial environments. In a power plant’s turbine control system, where input sensors are powered by 480 VAC and the VMEbus operates at 5 VDC, this isolation prevents voltage spikes from corrupting data—ensuring accurate measurement of steam temperature (±1 VDC signal) even during generator load changes. The module’s compliance with IEC 61000-6-4 (enhanced EMC immunity) further shields it from electromagnetic interference (EMI) from nearby transformers, making it suitable for use in heavy industrial settings like steel mills or mining operations.

Temperature-Compensated Calibration and BIST

The Motorola VME172PA-652SE’s temperature-compensated calibration adjusts the ADC/DAC’s output based on ambient temperature, minimizing drift (typically <0.0001% per °C) that would degrade accuracy in uncompensated modules. For example, in a desert-based solar farm where cabinet temperatures range from -10°C (night) to 70°C (day), this feature ensures the module maintains 24-bit precision across the entire temperature range—critical for optimizing solar panel efficiency. The built-in self-test (BIST) validates ADC/DAC functionality on startup or demand, allowing technicians to identify faults (e.g., a failing DAC channel) without external test equipment. This reduces maintenance time by 50% compared to modules requiring manual calibration and testing.

Typical Application Scenarios

The Motorola VME172PA-652SE excels in precision-critical industrial environments, working with SBCs like the Motorola MVME5500 and memory modules like the Motorola MVME147S-1. In semiconductor manufacturing, it monitors and controls the chemical vapor deposition (CVD) process: 16 input channels capture microvolt-level signals from pressure sensors (±1 VDC) and temperature probes (±2.5 VDC) inside the CVD chamber, while 8 output channels regulate gas flow valves (4–20 mA) and heater elements (0–10 VDC). The Motorola MVME5500 processes this data in real time, using the Motorola MVME147S-1’s DRAM to buffer high-volume sensor data. The module’s 24-bit precision ensures uniform film thickness across the wafer, while its isolation prevents EMI from nearby RF generators from corrupting data.

In medical device testing (e.g., MRI machine calibration), the Motorola VME172PA-652SE measures low-noise signals from gradient coils (±5 VDC) and transmits control signals to magnet power supplies (0–10 VDC). Its 24-bit ADC captures 0.1 µV variations in coil current—essential for optimizing image resolution—while its galvanic isolation protects sensitive MRI electronics from high-voltage gradients. The Motorola MVME712/M transmits test data to a central workstation, where engineers analyze performance against regulatory standards (e.g., FDA Class III medical device requirements). The module’s -40°C–70°C temperature range also withstands the extreme conditions of climate-controlled test chambers.

For automotive battery testing, the Motorola VME172PA-652SE monitors charge/discharge cycles: 8 input channels measure battery voltage (0–10 VDC) and current (4–20 mA via current shunts), while 8 output channels control charge/discharge circuits (0–5 VDC). The Motorola MVME5500 uses the module’s data to generate charge cycle profiles, storing historical data in the Motorola MVME147S-1’s NVRAM for long-term analysis. The module’s overcurrent protection prevents damage to test equipment if a battery short-circuits, while its temperature compensation ensures accurate measurements even as the battery heats up during fast charging.

MOTOROLA VME172PA-652SE

Related Model Recommendations

Motorola MVME5500: VME SBC. Host controller for Motorola VME172PA-652SE; processes 24-bit analog data, executes control logic, and uses the module’s outputs to regulate industrial processes—critical for leveraging the module’s precision.

Motorola MVME147S-1: Memory module. Complements Motorola VME172PA-652SE; its DRAM buffers high-volume analog data (e.g., 500 kSPS aggregate) for the Motorola MVME5500, while its NVRAM stores calibration parameters for the module.

Motorola MVME162PA-344E: Enhanced analog input module. Predecessor to Motorola VME172PA-652SE; 14-bit ADC, 16 input channels. Suitable for non-critical applications (e.g., basic temperature monitoring) where 24-bit precision is unnecessary.

Motorola FAB 0340-1049: Power supply module. Primary power source for Motorola VME172PA-652SE; delivers stable ±12 VDC for the module’s isolation circuits and +5 VDC for the ADC/DAC.

Motorola MVME712/M: VME communication module. Transmits Motorola VME172PA-652SE’s analog data (via Motorola MVME5500) to SCADA/DCS systems; enables remote monitoring of precision processes (e.g., semiconductor CVD).

Emerson RSTi-EP AI/AO Module: Modern Ethernet-based analog I/O module. Replacement for Motorola VME172PA-652SE in systems migrating from VME to Ethernet; 24-bit ADC/16-bit DAC, Ethernet connectivity, and compatibility with Motorola MVME5500 via Gigabit Ethernet.

Motorola MVME162-212: Digital I/O module. Works with Motorola VME172PA-652SE in hybrid systems; the Motorola MVME5500 uses digital inputs (e.g., safety interlocks) from the MVME162-212 to enable/disable analog control via the VME172PA-652SE.

Keysight 34970A: Data acquisition switch unit. Paired with Motorola VME172PA-652SE for multi-channel testing; expands the module’s input capacity by switching between 20+ sensors, ideal for aerospace component testing.

Installation, Commissioning and Maintenance Instructions

Installation Preparation

Before installing Motorola VME172PA-652SE, power off the VME chassis and disconnect the Motorola FAB 0340-1049 power supply to prevent electrical shock. Verify the chassis has an available 6U VME slot and that the VME backplane is VME 3.0 compliant (for 64-bit bus functionality). Check the power supply capacity: ensure it can deliver +5 VDC (3.0 A max), +12 VDC (0.8 A), and -12 VDC (0.6 A) to avoid underpowering the module’s ADC/DAC and isolation circuits. Use an anti-static wristband and mat to protect the module’s 24-bit ADC from ESD damage—critical for maintaining precision. Gather tools: Phillips-head screwdriver (for chassis mounting), shielded twisted-pair cables (for input/output wiring), a torque wrench (to tighten terminal screws to 0.5–0.8 N·m), and a precision multimeter (±0.001 V/A accuracy) for calibration. Avoid installing near high-voltage equipment (e.g., MRI magnets) or heat sources (e.g., power resistors) to prevent EMI or thermal drift.

Commissioning and Maintenance

For commissioning, insert the Motorola VME172PA-652SE into the VME slot and secure it. Connect input sensors (e.g., pressure transducers, thermocouples) to the module’s differential terminals, using shielded cables to minimize noise. Wire output channels to actuators (e.g., valves, pumps), ensuring correct polarity for current/voltage signals. Power on the Motorola FAB 0340-1049 and Motorola 30-W2960B01A, then check the module’s LEDs: green “POWER” confirms voltage; blinking “ACTIVE” LEDs indicate data acquisition/transmission; “CAL OK” (green) signals successful calibration. Use the Motorola MVME5500’s configuration software to set input ranges/gain and output modes (voltage/current) per channel. Run the BIST to validate ADC/DAC functionality, then calibrate the module using a NIST-traceable voltage/current source—enabling temperature compensation to correct for ambient conditions. Test closed-loop control by adjusting an input sensor (e.g., increasing pressure) and verifying the module’s output adjusts accordingly (e.g., opening a valve).

For maintenance: Inspect the module monthly for loose cables or damaged shields—repair immediately to avoid noise ingress. Clean the module quarterly with compressed air (low pressure) to remove dust from the heatsink and VME connector (prevents overheating and signal degradation). Re-calibrate semi-annually (or after temperature extremes) using a precision source—this maintains 24-bit precision by correcting for ADC/DAC drift. Check the module’s isolation resistance annually using a megohmmeter (ensure >100 MΩ between channels and bus) to verify noise immunity. If the BIST fails, use the Motorola MVME5500’s diagnostic tools to isolate the issue (e.g., a