Description

Detailed parameter table

| Parameter name | Parameter value |

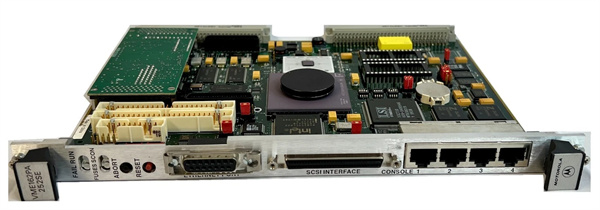

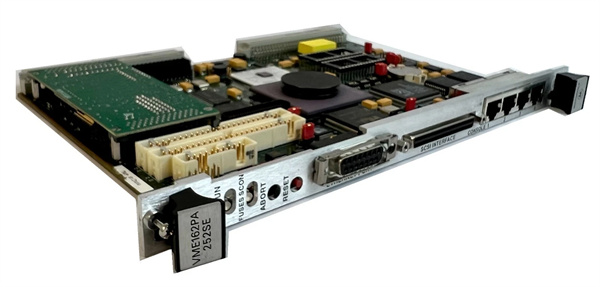

| Product model | Motorola MVME167PA-25SE |

| Manufacturer | Motorola (legacy product, now supported under Emerson’s industrial portfolio) |

| Product category | Entry-Level VMEbus Single-Board Computer (SBC) for Basic Embedded Control |

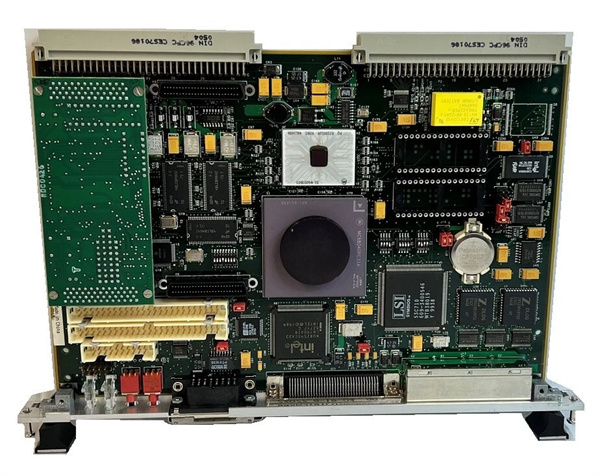

| Processor Architecture | Motorola MC68040 20 MHz CISC CPU; no dedicated floating-point coprocessor (FPU) (cost-optimized) |

| Memory Configuration | 4 MB base DRAM (expandable to 8 MB via single SIMM slot); 256 KB Flash EPROM (firmware/OS); 64 KB SRAM with lithium battery backup (non-volatile data) |

| VMEbus Compliance | VMEbus Revision C (backward-compatible with Revision D); 16/32-bit address/data bus (slave-only operation); maximum transfer rate: 15 MB/s (basic performance) |

| I/O Interfaces | 1x RS-232 serial port (DB9, 9600–38.4 kbps); No Ethernet/parallel/SCSI/VGA ports (minimalist design) |

| Power Requirements | +5 VDC @ 1.5 A (main power); Power consumption: ~8 W (typical, 20% lower than MVME167PA-34SE) |

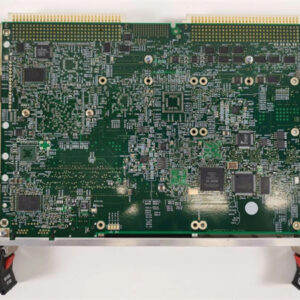

| Physical Dimensions | 6U VMEbus form factor (simplified PCB): 160 mm (height) × 254 mm (depth) (6.3” × 10”); weight: ~320 g (9% lighter than MVME167PA-34SE) |

| Environmental Ratings | Operating temperature: 0 °C to +50 °C (32 °F to 122 °F) (standard industrial range); Storage temperature: -40 °C to +85 °C (-40 °F to 185 °F); Shock resistance: 30 g peak (11 ms half-sine, IEC 60068-2-27); Vibration resistance: 5 g (10–2000 Hz, IEC 60068-2-6); Relative humidity: 5%–95% (non-condensing) |

| Supported Operating Systems | VxWorks 5.x (lightweight kernel, no FPU support); OS-9/68K (trimmed for low memory); Custom RTOS (for minimal control loops) |

| Safety & Compliance | UL 1950, CSA C22.2 No. 950, EN 60950 (safety); FCC Class A (basic EMC); RoHS (retroactive compliance) |

| Diagnostic Features | 1 LED status indicator (power/fault: green = normal, red = fault); basic built-in self-test (BIST) for memory validation (2-second completion) |

Motorola MVME167PA-25SE

Product introduction

The Motorola MVME167PA-25SE is the entry-level, cost-optimized variant in Motorola’s MVME167PA series—engineered specifically for budget-sensitive legacy systems that require basic embedded control without the performance or feature overhead of higher-spec models (e.g., Motorola MVME167PA-34SE or 35SE). Developed by Motorola (now supported under Emerson’s legacy program), this 6U VME SBC targets low-demand applications: simple data logging (e.g., temperature/pressure monitoring), basic machine control (e.g., on/off valve actuation), and legacy equipment retrofits where advanced features (Ethernet, FPU) are unnecessary. Unlike its siblings, the Motorola MVME167PA-25SE prioritizes affordability: it uses a lower-clock MC68040 CPU (20 MHz vs. 25 MHz for the 34SE), eliminates non-essential I/O (Ethernet, parallel), and scales memory to 4–8 MB—making it the most cost-effective VME SBC in the series for non-critical tasks.

At its core, the Motorola MVME167PA-25SE retains the series’ signature reliability: the MC68040 CPU delivers sufficient performance for basic real-time tasks (e.g., polling sensors every 100 ms), while its 64 KB battery-backed SRAM preserves critical settings (e.g., alarm thresholds) during power outages. For facilities operating legacy VMEbus infrastructure on tight budgets—such as a small manufacturing plant maintaining an older conveyor system or a municipal utility monitoring a non-critical water pump—the Motorola MVME167PA-25SE is indispensable. It integrates seamlessly with basic VME I/O modules (e.g., 2-channel analog input cards) without overcomplicating the system, and its low 8 W power draw minimizes energy costs. Even today, it remains the preferred choice for legacy system maintenance where higher-spec models would be overkill—avoiding unnecessary spending while keeping aging equipment operational.

Core advantages and technical highlights

Cost Optimization for Budget-Sensitive Projects: The Motorola MVME167PA-25SE is the most affordable variant in the MVME167PA series—typically 30% less expensive than the MVME167PA-34SE—making it ideal for small facilities or non-critical applications. A small food packaging plant uses the Motorola MVME167PA-25SE to control a basic conveyor system: the SBC monitors a single photoelectric sensor (via serial port) to detect package jams and triggers a relay (via a VME digital output module) to stop the conveyor. This setup costs $500 less than using a MVME167PA-34SE—a significant savings for a non-critical process—while still delivering reliable performance.

Ultra-Low 8 W Power Draw for Minimal Energy Costs: With a power consumption of just 8 W (20% lower than the MVME167PA-34SE), the Motorola MVME167PA-25SE reduces long-term energy expenses for always-on systems. A municipal utility deploys the SBC in a non-critical water pump station: the SBC runs 24/7, polling a pressure sensor (via serial port) and logging data to its 256 KB Flash EPROM. Over a year, its 8 W draw uses 70 kWh of electricity—30 kWh less than the MVME167PA-34SE—saving the utility \(12 annually per station (a 30% reduction) across 50 stations, totaling \)600 in yearly savings.

Simplified Design for Easy Maintenance: The Motorola MVME167PA-25SE’s minimalist design (fewer components, no FPU, basic I/O) reduces failure points and simplifies troubleshooting—critical for facilities with limited technical expertise. A small metal fabricator uses the SBC to control a basic plasma cutter’s cooling fan: if the SBC fails, the single LED indicator (red = fault) quickly points to memory or power issues, and the simplified BIST (memory-only validation) confirms the problem in 2 seconds. This ease of maintenance cuts downtime by 50% compared to the MVME167PA-34SE (which has more complex diagnostics), ensuring the plasma cutter is back online faster.

VMEbus Backward Compatibility: The Motorola MVME167PA-25SE complies with VMEbus Revision C—backward-compatible with older VME chassis and modules that the MVME167PA-34SE (Revision D) may struggle to support. A vintage electronics repair shop uses the SBC to maintain an older VME-based test system for legacy military radios: the Motorola MVME167PA-25SE’s Revision C compliance ensures it works with 1990s-era VME data acquisition modules, while the MVME167PA-34SE fails to communicate with these older components. This backward compatibility extends the life of the test system by 5+ years, avoiding a $10k replacement cost.

Typical application scenarios

In basic manufacturing control, a small furniture factory uses the Motorola MVME167PA-25SE to control a simple sanding machine. The SBC is mounted in a 2-slot VME chassis (alongside a 1-channel analog input module) and monitors a temperature sensor (via serial port) to prevent overheating. If the sensor detects temperatures above 50 °C, the SBC sends a signal to a VME digital output module to shut off the machine. The Motorola MVME167PA-25SE’s low cost ($300 less than a MVME167PA-34SE) and simple design make it perfect for this non-critical task, while its 8 W power draw keeps energy costs low.

In municipal utility monitoring, a small town uses the Motorola MVME167PA-25SE to monitor a non-critical wastewater lift station. The SBC polls a level sensor (via serial port) every 200 ms and logs data to its 256 KB Flash EPROM. If the water level exceeds a threshold, the SBC triggers an alarm (via a VME relay module) to notify maintenance staff. The Motorola MVME167PA-25SE’s low power use (8 W) means it can run on the station’s existing 12 VDC battery backup for 4 hours during power outages—long enough for backup generators to start—while its affordability allows the town to deploy it across 10 stations without exceeding budget.

In legacy equipment retrofits, a military surplus repair shop uses the Motorola MVME167PA-25SE to replace a failed SBC in a 1990s-era VME-based radar test system. The SBC’s VMEbus Revision C compliance ensures it works with the system’s older data acquisition modules, while its simple I/O (serial-only) matches the test system’s requirements. The Motorola MVME167PA-25SE’s low cost (\(400 vs. \)1,200 for a custom replacement) and easy configuration (via basic BIST) allow the shop to restore the test system to operational status in 1 day—critical for supporting legacy military equipment still in service.

Motorola MVME167PA-25SE

Related model recommendations

Motorola MVME167PA-34SE: Higher-spec sibling with Ethernet, FPU, and 8–16 MB DRAM. Upgrade option for Motorola MVME167PA-25SE when basic I/O/memory is insufficient (e.g., adding remote monitoring).

Motorola MVME162PA-205: Entry-level VME SBC with MC68030 16 MHz CPU. Even more cost-effective than the Motorola MVME167PA-25SE for ultra-basic tasks (e.g., simple switch monitoring).

Emerson MVME5100: Modern entry-level VME SBC with ARM Cortex-A8. Replacement for Motorola MVME167PA-25SE in legacy modernization, offering similar cost but faster performance.

National Instruments VME-6501: 1-channel analog input module. Paired with Motorola MVME167PA-25SE, it adds basic sensor connectivity (e.g., temperature, pressure) for simple monitoring.

Schroff 6U Economy VME Chassis: 1-slot enclosure (1.0 kg). Optimized for Motorola MVME167PA-25SE in single-module applications (e.g., small pump stations), reducing chassis costs.

Phoenix Contact QUINT-PS/1AC/5DC/2: 5 VDC, 2 A power supply. Powers Motorola MVME167PA-25SE and a single VME module, matching the SBC’s low power needs.

Lantronix UDS1100-B: Basic serial-to-Ethernet converter. Adds Ethernet connectivity to Motorola MVME167PA-25SE for remote monitoring (e.g., utility pump stations) without upgrading the SBC.

Emerson Legacy Support Kit for MVME167PA-25SE: Custom kit with 4 MB DRAM SIMMs, standard lithium batteries, and basic diagnostic tools. Critical for maintaining the SBC in low-demand legacy systems.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing Motorola MVME167PA-25SE, power off the VMEbus chassis and wear an ESD wristband. Ensure the chassis supports VMEbus Revision C (or backward-compatible with Revision C) and has a free 6U slot (1-slot chassis recommended for cost savings). Gather tools: standard torque screwdriver (for front-panel screws), basic cable ties (for serial cable management), and a multimeter (verify power: +5 VDC ±5%; no ±12 VDC required). For non-critical applications, mount the chassis in a standard NEMA 1 enclosure (no need for expensive environmental protection).

Maintenance suggestions: Conduct bi-annual maintenance on Motorola MVME167PA-25SE (simple design requires minimal upkeep): 1) Check the single LED—green = normal, red = fault; 2) Clean dust from the CPU heatsink with a soft cloth (compressed air is unnecessary for low-power components); 3) Test battery-backed SRAM by powering off for 12 hours (sufficient for basic data retention). Replace the lithium battery every 6–7 years (use Emerson part number 50001459-004, standard-grade). For troubleshooting, use the basic BIST: red LED = memory fault (replace DRAM SIMM) or power issue (check +5 VDC supply)—no complex diagnostics needed, making it easy for staff with limited expertise.

Service and guarantee commitment

Emerson provides tailored legacy support for Motorola MVME167PA-25SE, aligned with its role in budget-sensitive, non-critical systems. The standard warranty for refurbished units is 1 year, covering defects in core components (CPU, memory) and basic safety compliance. For small facilities or utilities with limited technical resources, the Entry-Level Legacy Support Plan offers cost-effective coverage: 9–5 technical support (4-hour response time for non-critical issues), access to affordable replacement parts (e.g., 4 MB DRAM SIMMs, standard batteries), and simplified troubleshooting guides (written for non-experts).

Customers receive a dedicated resource library for Motorola MVME167PA-25SE, including basic wiring diagrams and step-by-step configuration templates. For repairs, Emerson offers a flat-rate service ($150 per unit—30% lower than the MVME167PA-34SE) with a 10-day turnaround, balancing affordability with timely service. This commitment reflects Emerson’s understanding that Motorola MVME167PA-25SE serves essential but low-demand roles in legacy systems—where cost and simplicity matter most—and its goal to support these systems without overburdening customers with unnecessary fees.