Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

|---|---|

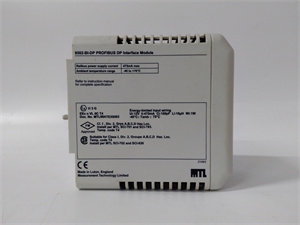

| Product Model | 8502-BI-DP |

| Manufacturer | Eaton MTL |

| Product Category | Bus Interface Module |

| Communication Protocol | Profibus-DP (Slave) |

| Data Transmission Speed | Up to 6 Mbaud |

| I/O Module Support | Connects up to 24 I/O modules |

| Input Voltage | 24 V DC |

| Current Consumption | 100 mA |

| Operating Temperature Range | -20°C to +60°C |

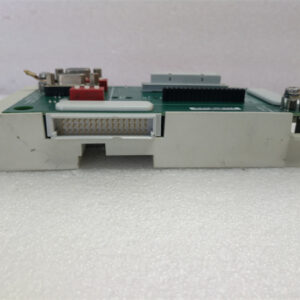

| Dimensions (L×W×H) | 120 mm × 80 mm × 45 mm |

| Weight | 0.350 kg |

| Certifications | CE, UL, RoHS |

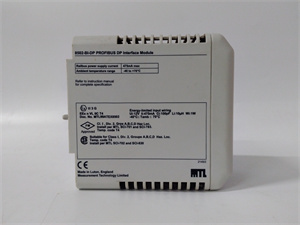

MTL 8502-BI-DP

Product Introduction

The MTL 8502-BI-DP is a Bus Interface Module (BIM) designed for the MTL 8000 I/O system, manufactured by Eaton MTL. It functions as a bridge between the MTL 8000 I/O modules and a Profibus-DP host network, enabling efficient data exchange between field devices and the control system. This module supports high-speed data acquisition and transmission, with a LAN operation speed of up to 6 Mbaud, facilitating real-time process control.

Core Advantages and Technical Highlights

High-Speed Data Acquisition: The 8502-BI-DP supports fast data collection from I/O modules with a LAN operation speed of up to 6 Mbaud. This facilitates real-time process control.

Master Configuration: The Profibus master can parameterize the 8502-BI-DP for optimal system configuration.

Slave Device: The module operates as a slave device on the Profibus-DP network, ensuring smooth integration with the host system.

Extended Diagnostics: The 8502-BI-DP provides extended diagnostic functions for module and channel status, supporting up to 24 I/O modules.

Robust Design: The module is designed for use in harsh industrial environments, featuring an operating temperature range of -20°C to +60°C and humidity range of 5% to 95% non-condensing.

Hazardous Area Compatibility: The 8502-BI-DP is designed for use in hazardous environments, featuring explosion-proof characteristics to ensure safe operation.

MTL 8502-BI-DP

Typical Application Scenarios

The MTL 8502-BI-DP is widely used in various industrial sectors, including power plants, chemical processing, and manufacturing facilities. It is particularly useful for:

-

Process Control: Monitoring and controlling parameters such as temperature, pressure, and flow rates in chemical plants and power stations.

-

Data Acquisition and Monitoring: Integrating with SCADA systems to monitor and record the operating status of various devices and systems in real-time.

-

Hazardous Area Applications: Ensuring safe and efficient operation in environments with explosive gases or dust.

Related Model Recommendations

-

8103-AI-TX: An 8-channel analog input module, suitable for precise measurement.

-

8104-AO-IP: An 8-channel analog output module, ideal for precise control of actuators and other devices.

-

8119-VI-05: An 8-channel voltage input module, suitable for applications requiring voltage signal acquisition.

-

8109-DI-DC: An 8-channel digital input module, providing versatile control options for industrial automation.

Installation, Commissioning, and Maintenance Instructions

Installation Preparation: Before installing the MTL 8502-BI-DP, ensure the environment meets the specified temperature and humidity requirements. Prepare the necessary tools, such as a screwdriver and multimeter, and ensure the installation area is free from dust and moisture. Follow the provided installation manual carefully to ensure proper grounding and connection of the module. Always disconnect the power source before starting the installation process to avoid electrical shock.

Maintenance Suggestions: Regularly inspect the 8502-BI-DP for signs of damage or wear, such as loose connections or corrosion. Clean the module periodically to remove dust and debris, which can affect performance and longevity. If any issues are detected, such as signal errors or communication failures, consult the troubleshooting guide or contact a professional for assistance. Replace any damaged components promptly to maintain optimal performance and reliability.

Service and Guarantee Commitment

The MTL 8502-BI-DP is backed by a comprehensive warranty, ensuring customer satisfaction and peace of mind. Eaton MTL offers technical support and service to assist with installation, troubleshooting, and maintenance. Our commitment to quality and customer service ensures that the 8502-BI-DP will deliver reliable performance for years to come.