Description

Detailed parameter table

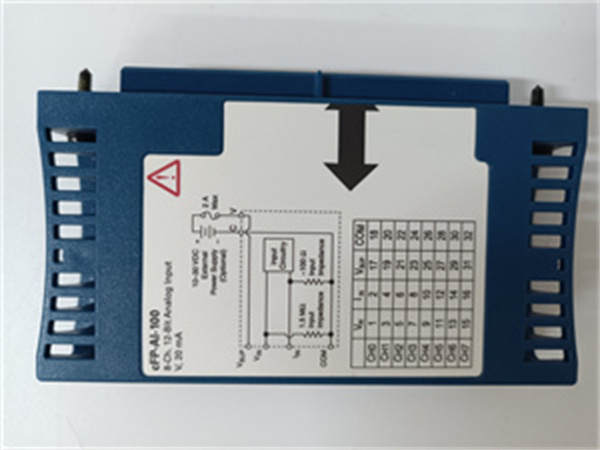

| Parameter name | Parameter value |

| Product model | NI CFP-AI-100 |

| Manufacturer | National Instruments (NI) |

| Product category | 8-Channel Analog Input Module for CompactFieldPoint System |

| Input Channels | 8 differential channels (configurable as 16 single-ended with external wiring) |

| Input Signal Range | ±10 V, ±5 V, ±2.5 V, ±1.25 V, 0-10 V, 0-5 V (software-selectable per channel) |

| Resolution | 16-bit ADC |

| Sampling Rate | 100 kS/s (aggregate); 12.5 kS/s per channel (when scanning all 8 channels) |

| Accuracy | ±0.05% of full scale (typical at 25 °C) |

| Input Impedance | 100 MΩ (minimum) |

| Common-Mode Rejection Ratio (CMRR) | 80 dB (minimum at 50/60 Hz) |

| Operating Temperature Range | -40 °C to 70 °C (extended industrial grade) |

| Storage Temperature Range | -40 °C to 85 °C |

| Power Requirements | 8-32 VDC (from CompactFieldPoint chassis); 1.5 W typical |

| Chassis Compatibility | NI CompactFieldPoint chassis (NI CFP-1804, NI CFP-1808, NI CFP-1810) |

| Communication | Integrated into CompactFieldPoint backplane (EtherNet/IP via chassis) |

| Dimensions (W×H×D) | 3.2 in × 5.5 in × 1.6 in (81 mm × 140 mm × 41 mm) |

| Weight | 4.2 oz (120 g) |

| Key Functions | Analog signal acquisition, channel multiplexing, industrial signal conditioning |

| Safety Certifications | UL 61010-1, CSA C22.2 No. 61010-1, IEC 61010-1, ATEX Zone 2 |

NI CFP-AI-100

Product introduction

The National Instruments CFP-AI-100 is a rugged 8-channel analog input module designed for the CompactFieldPoint industrial automation system, engineered to acquire high-precision analog signals in harsh environments. As a core component of NI’s distributed measurement ecosystem, it excels in capturing voltage-based signals from sensors, transducers, and industrial equipment—making it ideal for applications ranging from factory floor monitoring to remote infrastructure sensing.

Optimized for flexibility and durability, the NI CFP-AI-100 supports multiple input ranges (±10 V to 0-5 V) with software-selectable configurations per channel, allowing it to interface with diverse sensors such as pressure transducers, level transmitters, and temperature converters. When installed in a CompactFieldPoint chassis like the NI CFP-1804, the NI CFP-AI-100 leverages the system’s rugged design and EtherNet/IP connectivity to transmit data to central control systems, even in extreme temperatures (-40 °C to 70 °C) or high-vibration environments. Its 16-bit resolution and 100 kS/s aggregate sampling rate ensure accurate capture of both steady-state and dynamic signals, while its industrial certifications (ATEX Zone 2) make it suitable for hazardous locations.

Core advantages and technical highlights

Industrial-Grade Ruggedness for Harsh Environments:

The NI CFP-AI-100 is built to withstand the toughest industrial conditions, with an operating temperature range of -40 °C to 70 °C—far exceeding commercial-grade modules. It resists vibration (5 g rms, 10-500 Hz) and shock (50 g peak, 11 ms), ensuring reliable operation in environments like oil rigs, mining equipment, or outdoor weather stations. Unlike lab-focused modules, the NI CFP-AI-100 also carries ATEX Zone 2 certification, allowing safe use in areas with potentially explosive atmospheres (e.g., chemical processing plants). For example, in a desert solar power facility, the module continues to accurately measure inverter voltages despite daily temperature swings from -10 °C to 60 °C.

Flexible Channel Configuration for Mixed Signals:

With 8 differential or 16 single-ended channels and software-selectable ranges (±10 V to 0-5 V), the NI CFP-AI-100 adapts to diverse sensor types in a single module. This eliminates the need for multiple specialized modules, reducing system cost and complexity. A water treatment plant, for instance, can use the NI CFP-AI-100 to measure 4 differential signals from pressure transducers (±5 V) and 4 single-ended signals from pH controllers (0-10 V) via the same module in a NI CFP-1804 chassis. Each channel’s range is configurable via software, allowing quick reconfiguration when sensors are upgraded or processes change.

High-Precision Measurement for Critical Data:

The NI CFP-AI-100 delivers 16-bit resolution and ±0.05% typical accuracy, ensuring precise capture of small signal variations—critical for applications like energy monitoring or quality control. Its 100 kS/s aggregate sampling rate (12.5 kS/s per channel) handles dynamic signals, such as motor current fluctuations, while minimizing aliasing with built-in anti-aliasing filters. The module’s 100 MΩ input impedance also prevents loading on high-impedance sensors (e.g., capacitive level probes), maintaining signal integrity. In a manufacturing line monitoring hydraulic pressure, the NI CFP-AI-100 detects pressure drops as small as 0.01 V, enabling predictive maintenance before equipment failure.

Seamless Integration with CompactFieldPoint Ecosystem:

The NI CFP-AI-100 is designed to plug into CompactFieldPoint chassis (e.g., NI CFP-1804, NI CFP-1810), leveraging the system’s distributed architecture for easy scaling. The chassis provides power (8-32 VDC) and EtherNet/IP connectivity, allowing the NI CFP-AI-100 to transmit data to SCADA systems, PLCs, or cloud platforms without additional hardware. Integration with NI software (LabVIEW, NI-DAQmx) enables remote configuration—users can adjust ranges, sampling rates, or scaling factors from a central PC, eliminating the need for on-site visits. In a smart grid substation, this means technicians can reconfigure the NI CFP-AI-100 to monitor new voltage sensors without traveling to the remote site.

Typical application scenarios

In oil and gas production, the NI CFP-AI-100 monitors pipeline conditions in remote fields. Installed in a NI CFP-1804 chassis in an explosion-proof enclosure, it measures 8 differential signals: 4 from pressure transducers (±10 V) and 4 from temperature transmitters (4-20 mA converted to 0-5 V) along a 50-mile pipeline. The NI CFP-AI-100’s -40 °C to 70 °C operating range withstands extreme weather, while its ATEX certification ensures safety near volatile hydrocarbons. Data is transmitted via EtherNet/IP to a central SCADA system, where sudden pressure drops detected by the NI CFP-AI-100 trigger leak alerts—preventing environmental damage and production loss.

In manufacturing automation, the NI CFP-AI-100 is part of a quality control system for automotive assembly. Mounted in a NI CFP-1808 chassis on the production line, it acquires 16 single-ended signals: 8 from torque sensors (0-10 V) on bolt tighteners and 8 from vision system outputs (0-5 V) checking part alignment. The module’s 100 kS/s sampling rate captures transient torque spikes during fastening, while its 16-bit resolution ensures tight tolerance checks (±0.01 V). LabVIEW software processes data from the NI CFP-AI-100 in real time, rejecting parts with incorrect torque or alignment—reducing warranty claims and rework.

In renewable energy, the NI CFP-AI-100 monitors wind turbine performance. Installed in a NI CFP-1810 chassis in the turbine nacelle, it measures 8 differential signals: generator voltage (±10 V), bearing temperature (0-5 V), wind speed (0-10 V), and vibration (±2.5 V). The NI CFP-AI-100’s vibration resistance (5 g rms) ensures reliable operation during turbine rotation, while its wide temperature range handles -30 °C winters and 60 °C summers. Data is sent to a cloud platform via the chassis’ Ethernet connection, where anomalies detected by the NI CFP-AI-100 (e.g., rising bearing temperatures) trigger maintenance requests—maximizing turbine uptime.

NI CFP-AI-100

Related model recommendations

NI CFP-AI-110: A 4-channel high-precision analog input module, offering higher accuracy (±0.02% of full scale) than the NI CFP-AI-100 for critical measurements. It complements the NI CFP-AI-100 in systems requiring both general and precision channels.

NI CFP-DO-400: A 16-channel digital output module that pairs with the NI CFP-AI-100 in control systems. While the NI CFP-AI-100 acquires analog data, the NI CFP-DO-400 triggers actuators (e.g., valves, alarms) based on that data.

NI CFP-1804: A 4-slot CompactFieldPoint chassis that hosts the NI CFP-AI-100, providing power, Ethernet connectivity, and ruggedization. It is ideal for small-scale systems using 1-4 CompactFieldPoint modules.

NI CFP-1810: An 8-slot chassis for larger systems, supporting up to 8 modules including the NI CFP-AI-100. It offers expanded I/O capacity for complex monitoring setups (e.g., 64 analog inputs with 8 NI CFP-AI-100 modules).

NI CFP-CTR-502: A counter/timer module compatible with the NI CFP-AI-100 in mixed-signal systems. It measures frequency or pulse width (e.g., flow meter pulses) alongside the NI CFP-AI-100’s analog signals.

NI 9205: A C Series analog input module that serves as a modern alternative to the NI CFP-AI-100 in CompactRIO systems. It offers similar channel counts and ranges but with faster sampling rates (250 kS/s).

NI LabVIEW Real-Time: Software optimized for the NI CFP-AI-100, enabling real-time data processing and control. It simplifies programming of conditional logic (e.g., triggering alarms based on NI CFP-AI-100 measurements).

NI CFP-CB-100: A terminal block accessory for the NI CFP-AI-100, providing screw terminals for easy sensor wiring. It includes surge protection to shield the module from voltage transients in industrial environments.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI CFP-AI-100 into a CompactFieldPoint chassis (e.g., NI CFP-1804), power off the chassis and use ESD protection (wrist strap, mat) to prevent damage. Verify the chassis has an available slot and that its firmware is updated (via NI MAX) for compatibility. Required tools include a Phillips-head screwdriver (to secure the module) and wire strippers (for 22-14 AWG sensor wires). Mount the chassis in a location with minimal vibration and within the NI CFP-AI-100’s operating temperature range (-40 °C to 70 °C). For hazardous areas, ensure the enclosure meets ATEX Zone 2 requirements. When wiring sensors, use shielded twisted-pair cables and connect shields to the chassis ground to maximize noise rejection. Power the chassis with 8-32 VDC, ensuring the supply is regulated to avoid voltage spikes.

Maintenance suggestions

For daily maintenance of the NI CFP-AI-100, inspect terminal connections (via NI CFP-CB-100 block) monthly for corrosion or loose wires—tighten terminals and clean with a dry cloth if needed, as poor connections cause measurement errors. Calibrate the module annually using a precision signal generator (e.g., NI 4263A) to verify accuracy, especially in applications with tight tolerances. Monitor the module’s status via NI MAX; error codes may indicate channel overload or communication issues, which can often be resolved by checking wiring or rebooting the chassis. Every 6 months, inspect the chassis cooling vents for dust buildup—use compressed air to clean, as overheating reduces the NI CFP-AI-100’s lifespan. When replacing the module, save channel configurations in NI MAX to simplify reconfiguration of the new NI CFP-AI-100.

Service and guarantee commitment

National Instruments (NI) backs the NI CFP-AI-100 with a 2-year standard warranty, covering defects in materials and workmanship—including the ADC, input circuitry, and backplane connectors. If the NI CFP-AI-100 fails during the warranty period (e.g., due to accuracy drift or channel failure), NI provides free repair or replacement, with expedited service for critical industrial systems to minimize downtime. NI’s global technical support team is available 24/7 via email, phone, and chat, offering assistance with module configuration (e.g., range selection, scaling), troubleshooting integration with CompactFieldPoint chassis, and optimizing measurements in noisy environments. Additionally, NI provides lifetime access to firmware updates, driver downloads, and application notes for the NI CFP-AI-100, ensuring compatibility with legacy and modern control systems. This commitment reflects NI’s confidence in the NI CFP-AI-100’s industrial-grade reliability and supports customers in maintaining long-term measurement accuracy.