Description

1. Detailed Parameter Table

| Parameter Name | Parameter Value |

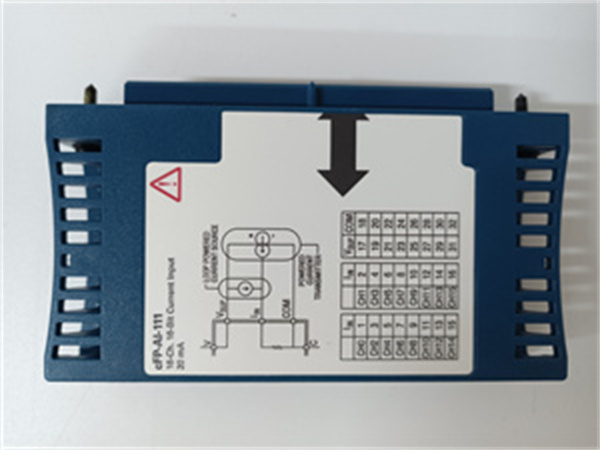

| Product Model | CFP – AI – 111 |

| Manufacturer | National Instruments (NI) |

| Product Category | 16 – Channel Analog Current Input Module |

| Input Channels | 16 single – ended analog current input channels |

| Input Ranges | Three types: ± 20 mA, 0 – 20 mA, and 4 – 20 mA |

| Resolution | 16 – bit |

| Filter Settings | Three levels: 50 Hz, 60 Hz, and 500 Hz |

| Update Rate | 3 Hz to 0.83 Hz |

| Transient Overvoltage Protection | 2,300 V rms |

| Input Impedance | 100 Ω |

| Overcurrent Protection | ± 30 mA |

| Over – ranging Feature | Can measure 5% beyond each range’s nominal value |

| Physical Dimensions | 4.3 x 4.3 x 3.6 in |

| Weight | 4.8 oz |

| Operating Temperature Range | – 40 to 70 °C |

| Storage Temperature Range | – 55 to 85 °C |

| Humidity Range | 10 to 90% rh (non – condensing) |

| Operating Vibration (Random/Sinusoidal) | 5 grms/5 g at 10 to 500 Hz |

| Warranty | Usually comes with a standard NI warranty, typically 3 years, but the exact duration can be confirmed through NI’s official channels |

NI CFP-AI-111

2. Product Introduction

The NI CFP – AI – 111 is a high – performance 16 – channel analog current input module designed specifically for the Compact FieldPoint system. It serves as a crucial interface for directly measuring milliamp – level current signals sourced from a wide array of sensors and transducers.

With its 16 single – ended analog input channels, the CFP – AI – 111 offers extensive connectivity options, enabling the simultaneous acquisition of multiple analog current signals. This is particularly useful in complex industrial and measurement setups where numerous sensors need to be monitored. The three selectable input ranges (± 20 mA, 0 – 20 mA, and 4 – 20 mA) provide flexibility, allowing users to adapt to different signal levels from various sensors. For example, in a temperature – monitoring application using a thermocouple with a specific current output range, the appropriate input range on the CFP – AI – 111 can be selected to ensure accurate signal acquisition.

The module’s 16 – bit resolution ensures high – precision measurements, capable of detecting even the slightest changes in the input current signals. This level of resolution is essential in applications where fine – grained data is required, such as in scientific research experiments or high – accuracy industrial process control.

3. Core Advantages and Technical Highlights

3.1 Integrated Filtering for Reduced Noise

The CFP – AI – 111 is equipped with three filter settings (50 Hz, 60 Hz, and 500 Hz). These comb filters are designed to reject harmonics or multiples of the fundamental frequency. At the fundamental frequency, they can achieve a rejection of 95 dB, and at least 60 dB at harmonics. In industrial environments, where electrical noise is prevalent, these filters play a vital role in ensuring that the acquired analog current signals are clean and accurate. For instance, in a factory setting with a lot of electromagnetic interference from machinery, the appropriate filter setting can be chosen to eliminate noise and obtain reliable sensor data.

3.2 Hot – Swappable Design

One of the standout features of the CFP – AI – 111 is its hot – swappable capability. This means that the module can be installed or removed from an already running and powered Compact FieldPoint backplane without disrupting the ongoing operation of the system. This is extremely beneficial in maintenance scenarios. For example, if a module needs to be replaced due to a malfunction, technicians can swap it out without shutting down the entire system, minimizing downtime and ensuring continuous operation of critical processes.

3.3 Overvoltage and Overcurrent Protection

The module offers 2,300 V rms transient overvoltage protection, safeguarding it from sudden voltage spikes that could potentially damage the internal components. Additionally, the integrated overcurrent protection, set at ± 30 mA, ensures that the module remains safe in case of abnormal current flow. In industrial applications where electrical faults are a concern, these protection features enhance the reliability and longevity of the CFP – AI – 111. For example, in a power – intensive industrial process where voltage fluctuations are common, the overvoltage protection mechanism will kick in to protect the module.

3.4 Over – ranging Feature

The over – ranging feature of the CFP – AI – 111 allows it to measure 5% beyond each range’s nominal value. For example, when the ± 20 mA range is selected, the module can actually measure up to ± 21 mA. This provides an extra margin of measurement flexibility, especially in situations where the input current signals may slightly exceed the expected range. It helps prevent signal clipping and ensures that no valuable data is lost.

4. Typical Application Scenarios

4.1 Industrial Process Control

In manufacturing plants, the CFP – AI – 111 can be used to monitor and control various processes. For example, in a chemical production facility, it can measure the current signals from sensors that monitor the flow rate, temperature, and pressure of chemical substances in pipelines. By accurately acquiring these analog current signals, the plant’s control system can make real – time adjustments to ensure optimal production conditions. In a bottling plant, it can be used to monitor the current output of sensors that detect the fill level of bottles, ensuring consistent product quality.

4.2 Energy Management Systems

In power generation and distribution systems, the CFP – AI – 111 is useful for monitoring the current in electrical circuits. In a solar power plant, it can measure the current output from solar panels, helping operators assess the performance of the panels and the overall power generation efficiency. In a smart grid system, it can be used to monitor the current flow in different sections of the grid, enabling better load management and ensuring grid stability.

4.3 Environmental Monitoring

For environmental monitoring applications, the CFP – AI – 111 can connect to sensors that measure parameters such as air quality, water quality, and weather conditions. In an air quality monitoring station, it can measure the current signals from sensors that detect pollutants like nitrogen oxides, sulfur dioxide, and particulate matter. This data can then be used to analyze air quality trends and take appropriate measures to protect the environment. In a water treatment plant, it can monitor the current output of sensors that measure the pH level, turbidity, and chemical composition of water, ensuring the effectiveness of the treatment process.

NI CFP-AI-111

5. Related Model Recommendations

5.1 Compact FieldPoint Backplane

The CFP – AI – 111 is designed to be used in conjunction with the Compact FieldPoint backplane. The backplane provides the necessary power and communication interface for the CFP – AI – 111 module. Different models of the Compact FieldPoint backplane can support varying numbers of modules, allowing users to expand their data acquisition systems as needed. For example, if a user initially has a small – scale data acquisition setup with a few CFP – AI – 111 modules and later needs to add more modules to monitor additional sensors, they can upgrade to a larger – capacity backplane.

5.2 Compatible Sensors and Transducers

There are numerous sensors and transducers that are compatible with the CFP – AI – 111. For current – based temperature sensors, such as those using the Seebeck effect, the CFP – AI – 111 can accurately measure their output current to determine the temperature. In pressure – sensing applications, piezoelectric transducers that convert pressure into an electrical current can be connected to the CFP – AI – 111. The wide range of compatible sensors and transducers makes the CFP – AI – 111 a versatile choice for different measurement needs.

6. Installation, Commissioning and Maintenance Instructions

6.1 Installation Preparation

Before installing the CFP – AI – 111, ensure that the Compact FieldPoint system is powered off. This is to prevent any electrical accidents during the installation process. Identify an appropriate slot on the Compact FieldPoint backplane for the module. Gather any necessary tools, such as a screwdriver if required to secure the module in place. When handling the CFP – AI – 111, be careful not to damage the connectors or any of the internal components. If connecting sensors or transducers to the module, make sure that the wiring is properly prepared, with the correct gauge of wire and appropriate connectors.

6.2 Commissioning Steps

Once the CFP – AI – 111 is installed, power on the Compact FieldPoint system. Use the appropriate software, such as NI – MAX (Measurement & Automation Explorer), to configure the module. Set the input ranges, filter settings, and other parameters according to the requirements of the application. Calibrate the module using the NIST – traceable calibration certificate provided with the module to ensure accurate measurements. Test the module by applying known current signals from a calibration source and verifying that the readings on the software match the expected values.

6.3 Maintenance Suggestions

Regularly inspect the CFP – AI – 111 for any signs of physical damage, such as bent connectors or cracks on the module casing. Check for loose connections between the module and the backplane, as well as between the module and the sensors or transducers. If there are issues with signal acquisition, such as incorrect readings or excessive noise, first check the filter settings and input ranges. If the problem persists, refer to the user manual for troubleshooting steps. In case of a malfunction, if a replacement part is needed, always use genuine NI replacement parts to maintain the performance and compatibility of the module. Periodically clean the module to remove any dust or debris that may have accumulated, as this can affect the electrical performance of the module.

7. Service and Guarantee Commitment

NI offers a comprehensive quality assurance program for the CFP – AI – 111. The module undergoes rigorous testing during the manufacturing process to ensure it meets high – performance and reliability standards. In terms of after – sales service, NI provides detailed user manuals and installation guides, which are available online for easy access. Technical support is accessible through user forums, where users can interact with NI experts and other users to solve any issues they may encounter. In case of a product defect within the warranty period (usually 3 years, but confirm through NI’s official channels), NI will provide repair or replacement services. This commitment to quality and customer support gives users confidence in the reliability of the CFP – AI – 111 for their data acquisition and process control needs.