Description

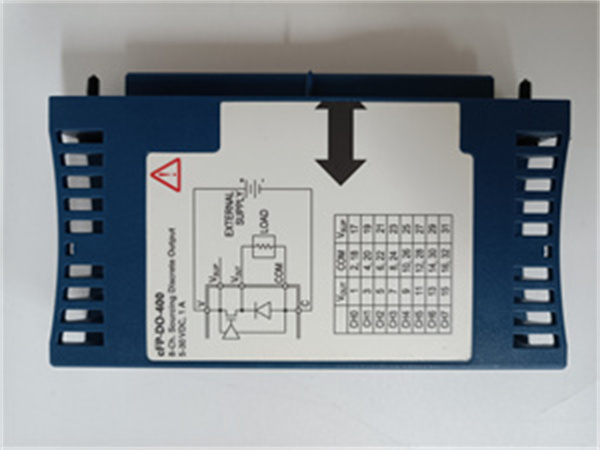

NI CFP – DO – 400 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | CFP – DO – 400 |

| Manufacturer | National Instruments |

| Product category | Compact FieldPoint digital output module |

| Channels | 8 digital output channels |

| Output voltage range | 5 – 30 VDC (sourcing) |

| Output impedance | 0.3 ohms for 10 – 30 V range |

| Update rate | 20 kHz for all channels |

| Output current per channel | Up to 2 A |

| Total output current (all channels) | Up to 8 A |

| Output delay time (on) | 20 µs |

| Output delay time (off) | 50 µs |

| Isolation | Optical bank isolation with 2300 VRMS breakdown isolation; no channel – to – channel isolation |

| Power supply | Built – in power supply bus; supports connection to external field – wired power supply |

| Status indicators | LED indicators for each channel to show switching status |

| Physical dimensions | 4.2 x 4.3 x 3.6 inches (106.68 x 109.22 x 91.44 mm) |

| Weight | 4.8 oz (136.08 g) |

| Operating temperature | – 40 °C to 70 °C |

| Storage temperature | – 55 °C to 85 °C |

| Relative humidity | 10 – 90% non – condensing |

| Operating vibrations (random/sinusoidal) | 5 grms / 5 g (10 Hz – 500 Hz) |

| Compliance standards | Complies with IEC 61010 – 1, EN 61010 – 1, UL 3121 – 1, UL 61010 c – 1, CAN/CSA C22.2 No. 1010.1 electrical safety standards |

| Part number | 777318 – 400 |

NI CFP-DO-400

Product introduction

The National Instruments CFP – DO – 400 is a high – performance 8 – channel digital output module designed for use within Compact FieldPoint systems. It plays a crucial role in converting digital control signals into outputs that can directly drive a variety of industrial devices, making it an essential component in industrial automation, control, and monitoring applications.

As part of the Compact FieldPoint family, the CFP – DO – 400 offers a combination of reliability, flexibility, and ease of use. Its ability to control digital signals within the 5 – 30 VDC range makes it suitable for a wide array of applications. The module uses a common ground plane for its output channels and features an update rate of 20 kHz, ensuring rapid response to changes in control signals. With built – in diagnostics and status indicators, the CFP – DO – 400 simplifies system maintenance and troubleshooting.

Core advantages and technical highlights

High – current output capabilities

The CFP – DO – 400 can provide up to 2 A of current per output channel, with a total output current of up to 8 A for all channels combined. This high – current capacity allows it to directly drive power – hungry devices such as relays, solenoids, and some types of motors. In an industrial manufacturing plant, for example, it can be used to control large – scale pneumatic valves that require a significant amount of current to operate. The ability to supply such high currents eliminates the need for additional power – amplifying circuitry in many cases, reducing system complexity and cost.

Fast update rate

With an update rate of 20 kHz for all channels, the CFP – DO – 400 can quickly adapt to changes in digital control signals. In high – speed production lines, such as those in the electronics manufacturing industry, this fast update rate enables the module to control the operation of pick – and – place robots with great precision. The robots can be instructed to perform rapid movements, such as quickly picking up and placing small electronic components on printed circuit boards. The quick response of the CFP – DO – 400 ensures that the robots can keep up with the fast – paced production requirements, increasing overall production efficiency.

Built – in diagnostics and status indicators

Each channel of the CFP – DO – 400 is equipped with an LED indicator that visually displays the switching status of the channel. This makes it easy for operators and maintenance personnel to quickly identify whether a particular channel is in an active or inactive state. In addition, the module has built – in diagnostics that continuously monitor its operation. If any issues are detected, such as over – current conditions or communication errors, the module can take appropriate action, such as reporting the error to the system controller. In a large – scale industrial automation system, these diagnostic features can significantly reduce downtime by allowing for the quick identification and resolution of problems.

Flexible power supply options

The CFP – DO – 400 features a built – in power supply bus and supports the connection of an external field – wired power supply. This flexibility in power supply options allows it to be used in a variety of environments. In industrial settings where there may be different power requirements or power sources available, the module can be configured to use the most suitable power supply. For example, in a remote industrial site where the main power supply may be unstable, an external backup power supply can be connected to the CFP – DO – 400 to ensure continuous operation. The multiple connections for power also provide a convenient way to distribute power to field devices that require external power.

Typical application scenarios

In industrial automation, the NI CFP – DO – 400 is extensively used to control a wide range of actuators. In a metal – processing factory, it can be used to control the operation of hydraulic presses. By sending digital control signals, the CFP – DO – 400 can precisely control when the press activates, applying the right amount of force at the right time to shape metal components. In a packaging plant, the module can control the operation of conveyor belts, turning them on and off as needed to move products through the packaging process smoothly. It can also control the operation of label – applying machines, ensuring that labels are accurately applied to products.

In smart home control systems, the CFP – DO – 400 can be used to control various electrical devices. For example, it can be integrated into a home – automation hub to control the opening and closing of electric curtains. Based on user – set schedules or sensor inputs (such as light sensors), the module can send digital signals to operate the curtain motors. It can also control the power supply to home appliances like air conditioners, heaters, and lights, allowing for remote or automated control of these devices. This can enhance the comfort and energy efficiency of a home.

In test and measurement applications, the CFP – DO – 400 can be used to generate digital test signals. In an electronics testing laboratory, it can be used to simulate the digital input signals that a circuit – board under test may receive. By controlling the output of the CFP – DO – 400, engineers can test the response of the circuit – board to different digital input patterns. This helps in validating the functionality and performance of the circuit – board before it is deployed in a real – world application.

NI CFP-DO-400

Related model recommendations

CFP – AI – 100: This analog input module can be paired with the CFP – DO – 400 in systems where both analog input and digital output are required. In a process control system, the CFP – AI – 100 can measure analog signals from sensors, such as temperature, pressure, or flow sensors. Based on the measured data, the CFP – DO – 400 can then be used to control digital actuators, such as valves or relays, to adjust the process accordingly. For example, in a chemical reactor control system, the CFP – AI – 100 can measure the temperature inside the reactor, and the CFP – DO – 400 can control the heating or cooling elements to maintain the desired temperature.

Compact FieldPoint Chassis: Similar to the CFP – AO – 210, appropriate Compact FieldPoint chassis, such as the CFP – 2020, are necessary to house the CFP – DO – 400 and other compatible modules. The chassis provides power, communication interfaces, and mechanical support, enabling seamless integration into a complete Compact FieldPoint system.

LabVIEW: NI’s LabVIEW software is also a powerful tool for programming and controlling the CFP – DO – 400. It offers a graphical programming environment with pre – built functions for digital I/O control, data acquisition, and system monitoring. Using LabVIEW, engineers can create user – friendly interfaces to monitor and control the output channels of the CFP – DO – 400. They can also develop complex control algorithms that take into account the digital output requirements based on various input parameters.

NI – DAQmx: This driver software is essential for communicating with the CFP – DO – 400. It provides a standardized interface for configuring the module, setting the output states, and handling errors. NI – DAQmx is compatible with various programming languages, including C, C++, and Python, giving developers the flexibility to choose the programming environment that best suits their application needs.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI CFP – DO – 400, ensure that the Compact FieldPoint system is powered off. Use an anti – static wristband to handle the module to prevent electrostatic discharge from damaging the sensitive electronics. Verify that the Compact FieldPoint chassis has an available slot that is compatible with the CFP – DO – 400. Connect the appropriate cables to the module’s output terminals, making sure to label and connect them correctly to the corresponding channels. Since the module has 8 digital output channels, proper labeling is crucial for accurate operation. Mount the module in the chassis and secure it using the provided hardware. After installation, power on the Compact FieldPoint system.

Commissioning

Install the NI – DAQmx driver software on the host computer that is connected to the Compact FieldPoint system. Use the NI – MAX (Measurement & Automation Explorer) utility to configure the CFP – DO – 400. Set the output voltage range and other relevant parameters according to the requirements of the connected devices. If an external power supply is used, ensure that it is properly configured and connected. Test the module by generating test signals from the host system and verifying that the correct digital states are outputted on each channel. If using LabVIEW, create a simple control VI (Virtual Instrument) to start controlling and monitoring the output channels of the CFP – DO – 400.

Maintenance suggestions

Regularly inspect the module’s connectors for any signs of corrosion, loose connections, or physical damage. Corrosion can affect the electrical conductivity and lead to incorrect digital outputs. If any issues are detected, clean the connectors using a suitable contact cleaner. Monitor the status LEDs on the module. The LEDs should accurately reflect the switching status of each channel. If an LED shows an incorrect state or is not functioning, check the module configuration and the connected devices. Periodically check the module’s performance by running diagnostic tests. Calibrate the module if necessary, following NI’s recommended calibration procedures. In case of a suspected module failure, use the on – board diagnostics and NI – MAX to troubleshoot the issue. If the problem persists, contact NI’s technical support for further assistance.

Service and guarantee commitment

The NI CFP – DO – 400 typically comes with a standard warranty, which covers defects in materials and workmanship for a specified period, usually 1 – 3 years depending on the region and purchase terms. NI’s global technical support team is available to provide assistance for installation, configuration, and troubleshooting. They can be reached via phone, email, or online support forums. NI also offers calibration services, either on – site or at their accredited calibration facilities, to ensure that the module continues to meet its specified performance requirements. For customers with complex or custom applications, NI’s professional services team can provide consulting, system integration, and software development services to optimize the use of the CFP – DO – 400 in their specific systems.