Description

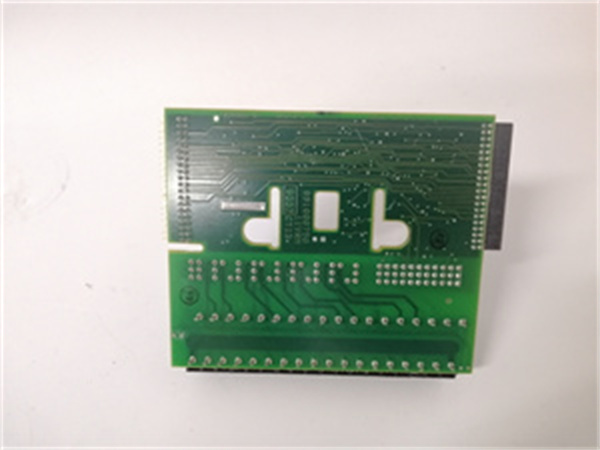

NI FP-TB-1 Detailed Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | FP-TB-1 |

| Manufacturer | National Instruments |

| Product category | Universal screw terminal base for FieldPoint systems |

| Termination type | Screw terminals |

| Number of terminals | 36 |

| Number of slots | 8 (accommodates 8 FieldPoint I/O modules) |

| Input voltage | 24 VDC |

| Operating temperature | -20 °C to 70 °C |

| Storage temperature | -40 °C to 85 °C |

| Physical dimensions | 105 mm x 92 mm x 43 mm |

| Weight | 200 g |

| Mounting options | DIN rail (35 mm standard) and panel mounting |

| Connector type | Screw terminals (accepts 22-14 AWG wire) |

| Local bus function | Transmits communication signals and distributes power to I/O modules |

| Interlock feature | Mechanical interlocking design for secure module installation |

| Compliance standards | CE, UL, CSA |

NI FP-TB-1

Product introduction

The National Instruments FP-TB-1 is a foundational component of the FieldPoint modular I/O system, serving as a universal screw terminal base that bridges FieldPoint I/O modules and field wiring. As a critical connectivity hub, the FP-TB-1 simplifies industrial system integration by providing a centralized point for signal routing, power distribution, and module mounting.

Designed for rugged industrial environments, the FP-TB-1 supports up to 8 FieldPoint I/O modules, leveraging a built-in local bus to transmit both communication signals and power—eliminating the need for separate wiring for each module. Its 36 screw terminals accommodate a wide range of wire gauges (22-14 AWG), making it compatible with diverse sensors, actuators, and control devices. Whether deployed in manufacturing plants, utility facilities, or environmental monitoring stations, the FP-TB-1 ensures reliable connections that withstand vibrations, temperature fluctuations, and harsh operating conditions.

Core advantages and technical highlights

Versatile connectivity

The FP-TB-1’s 36 screw terminals and 8 module slots enable flexible integration with virtually any FieldPoint I/O module, from analog input/output to digital and specialty modules. This versatility allows system designers to mix and match modules based on application needs—for example, combining temperature sensors with relay outputs—without requiring specialized terminal bases. The screw terminals provide a secure, vibration-resistant connection, critical in industrial settings where loose wiring can cause system failures.

Integrated power and communication

By incorporating a local bus that handles both power distribution and data transmission, the FP-TB-1 reduces system complexity and wiring costs. Instead of running separate power cables to each I/O module, the base distributes 24 VDC power through the bus, streamlining installation. This integrated design also ensures synchronized communication between modules and network interfaces (such as the FP-2010), enabling real-time data exchange in time-critical applications like process control.

Rugged design for industrial environments

Built to operate in -20 °C to 70 °C temperatures, the FP-TB-1 thrives in harsh conditions—from freezing warehouses to high-temperature factory floors. Its mechanical interlocking feature secures I/O modules in place, preventing disconnections due to vibrations or accidental bumps. The DIN rail and panel mounting options further enhance flexibility, allowing installation in standard control cabinets or custom enclosures.

Easy installation and maintenance

The FP-TB-1 simplifies setup with clear terminal labeling and tool-less DIN rail mounting. Screw terminals accept a wide wire gauge range, accommodating both fine control wiring and heavier power cables. For maintenance, the modular design allows individual I/O modules to be swapped without disconnecting field wiring, minimizing downtime during repairs or upgrades. Status LEDs on connected modules (when supported) remain visible through the base, enabling quick troubleshooting.

Typical application scenarios

In factory automation, the FP-TB-1 serves as the backbone of a machine control system. For example, in an automotive assembly line, it might connect proximity sensors (via an FP-AI-100 analog input module) to detect part presence, while linking to an FP-DO-400 digital output module to trigger robotic welders. The FP-TB-1 centralizes these connections, making it easy to trace signals and troubleshoot issues.

In water treatment plants, the FP-TB-1 integrates with level sensors, flow meters, and valve actuators. Its rugged design withstands the humid, chemical-exposed environment, while the local bus ensures reliable communication between sensors and a central SCADA system. Operators can quickly reconfigure the system by swapping modules—for instance, adding a pH sensor module—without rewiring the entire terminal base.

In renewable energy systems, such as solar farms, the FP-TB-1 connects inverter sensors, temperature probes, and grid monitoring devices. Its wide operating temperature range handles outdoor installations, and the secure mounting ensures modules stay connected despite wind and vibration. The integrated bus simplifies data transmission to a central controller, enabling real-time performance monitoring.

Related model recommendations

FP-2010: A FieldPoint intelligent Ethernet controller that pairs with the FP-TB-1 to enable networked control. The FP-2010 communicates with I/O modules via the FP-TB-1’s local bus, supporting remote monitoring and programming via LabVIEW.

FP-AI-111: A 16-channel analog current input module that connects to the FP-TB-1 to measure 4-20 mA signals from sensors (e.g., pressure transducers). The FP-TB-1 provides power and routes signals to the FP-AI-111 for processing.

FP-DO-400: An 8-channel digital output module that integrates with the FP-TB-1 to control relays, solenoids, or motors. The terminal base simplifies wiring between the FP-DO-400 and field devices.

FP-TB-2: A 16-slot terminal base that extends the FP-TB-1’s capabilities for larger systems. While the FP-TB-1 supports 8 modules, the FP-TB-2 accommodates 16, ideal for high-channel-count applications.

FP-1601: An Ethernet interface module that, when used with the FP-TB-1, connects FieldPoint systems to Ethernet networks. It leverages the FP-TB-1’s local bus to enable data transfer between I/O modules and a host PC.

NI FP-TB-1

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the FP-TB-1, power off the entire FieldPoint system. Select a mounting location within the operating temperature range (-20 °C to 70 °C) and ensure compliance with DIN rail (35 mm) or panel mounting requirements. Gather tools: a screwdriver for terminal connections, wire strippers (to prepare 22-14 AWG wire), and mounting hardware (included for panel installation).

Mount the FP-TB-1 securely—either on a DIN rail (slide into place and lock) or via panel screws. Connect the 24 VDC power supply to the designated terminals, ensuring correct polarity. Route field wiring to the terminal base, stripping wires to 6-8 mm, and secure each to the appropriate terminal (label wires to match the system diagram).

Commissioning

After wiring, insert FieldPoint I/O modules into the FP-TB-1’s slots, ensuring they lock into place via the mechanical interlock. Power on the system and verify module recognition using NI Measurement & Automation Explorer (MAX). Test signal transmission by connecting a test sensor/device to a terminal and checking for valid readings in the host software (e.g., LabVIEW). Confirm power distribution by verifying all modules power on—indicated by their status LEDs.

Maintenance suggestions

Inspect the FP-TB-1 quarterly for loose terminals, corrosion, or damaged wiring. Tighten screws if connections are loose, and clean terminals with isopropyl alcohol if corrosion is present. Check module interlocks to ensure modules are securely seated. For wire replacement, use 22-14 AWG wire and torque terminals to 0.5-0.6 Nm. Store spare FP-TB-1 units in a dry environment (-40 °C to 85 °C) to prevent component degradation. If modules fail to communicate, check the local bus connections and reset power to the base.

Service and guarantee commitment

The FP-TB-1 is backed by a 2-year warranty covering defects in materials and workmanship. National Instruments provides global technical support via phone, email, and online resources, including user manuals and troubleshooting guides. Calibration services are available to ensure terminal connections maintain signal integrity over time.

NI’s commitment to quality ensures the FP-TB-1 meets industrial reliability standards, with a mean time between failures (MTBF) exceeding 100,000 hours. For custom integration needs, NI’s professional services team offers system design assistance to optimize FP-TB-1-based solutions for specific applications, ensuring long-term performance and compatibility with evolving FieldPoint modules.