Description

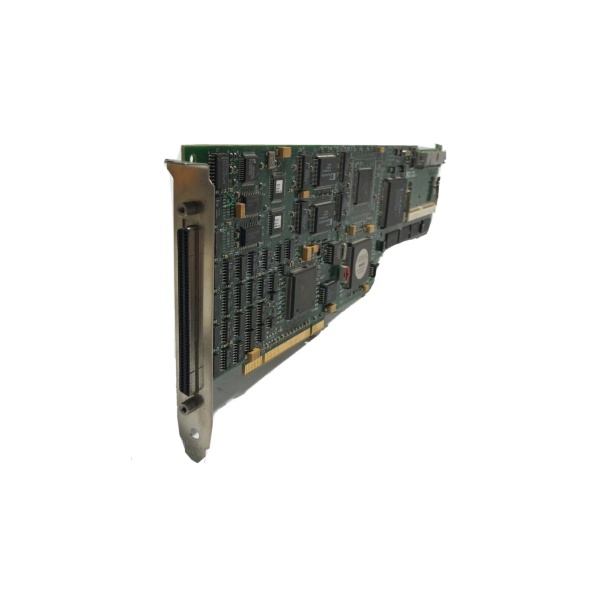

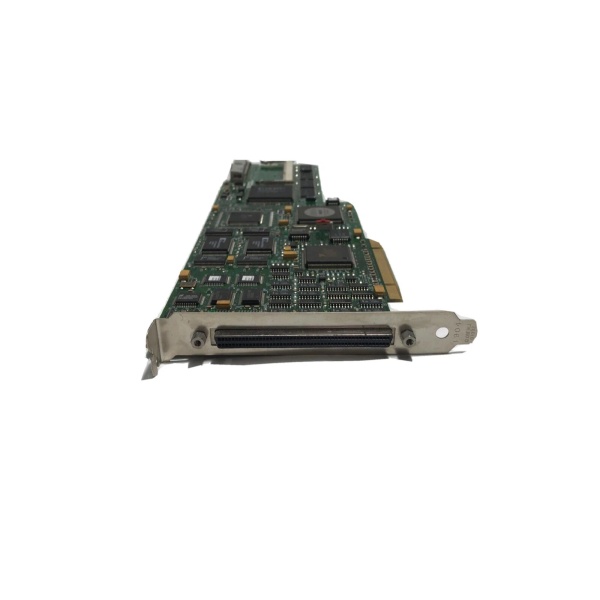

NI PCI-1424

- •

Model Number: PCI-1424 - •

Manufacturer: National Instruments - •

Product Type: PCI Image Acquisition Card (Frame Grabber) - •

Camera Interface: Camera Link (Base, Medium, Full configurations) - •

Pixel Clock Rate: 85 MHz maximum - •

Data Path: 8-tap configuration, 64-bit data path - •

PCI Interface: 64-bit/66 MHz PCI - •

Digital I/O: 4 opto-isolated inputs, 4 opto-isolated outputs - •

Trigger Modes: Software trigger, hardware trigger, triggered acquisition - •

Look-Up Table: 8-bit to 8-bit programmable LUT - •

Image Buffer: Scatter-gather DMA for efficient memory management - •

Connector: 26-pin MDR Camera Link connector - •

Supported Cameras: Area scan and line scan Camera Link cameras - •

Operating Temperature: 0°C to 55°C - •

Power Consumption: 5V @ 2.5A (from PCI bus) NI PCI-1424