Description

Detailed parameter table

| Parameter name | Parameter value |

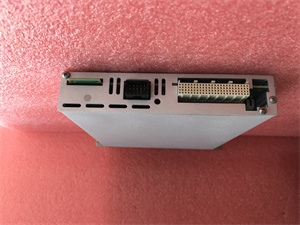

| Product model | NI PCI-3840 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Density PCI Digital I/O Module (Bidirectional) |

| Digital I/O Channels | 384 bidirectional lines (organized into 12 ports of 32 lines each); Software-configurable per-line direction (input/output) |

| Electrical Specifications | Logic levels: TTL/CMOS (5 V); Input threshold: 0.8 V (low), 2.0 V (high); Output drive current: ±24 mA per line; Sink current: 64 mA per port |

| Timing Performance | Max I/O update rate: 10 MHz (burst mode); 1 MHz (continuous mode); Setup time: 10 ns; Hold time: 5 ns; Propagation delay: 20 ns |

| Physical Dimensions | Standard PCI form factor (167.6 mm × 106.7 mm); Weight: ~220 g; Mounting: PCI 2.2/3.0 slots (32-bit/33 MHz); Compatible with PCI-X slots (backward compatible) |

| Interface & Connectivity | PCI bus (32-bit/33 MHz); 2× 200-pin SCSI-II connectors (front-panel) for I/O expansion; Supports DMA data transfer (scatter-gather); No external power required (powered via PCI slot) |

| Compatibility | Works with host PCs: Desktop/industrial PCs with PCI slots; Supported OS: Windows XP/Vista/7/10, NI Linux Real-Time; Compatible software: LabVIEW 8.0–2024, NI-DAQmx driver, NI TestStand |

| Environmental Requirements | Operating temperature: 0 °C–55 °C; Storage temperature: -20 °C–70 °C; Relative humidity: 10%–90% (non-condensing); Vibration resistance: 5 g (10 Hz–500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Signal Integrity | ESD protection: ±15 kV (air discharge), ±8 kV (contact discharge) per line; Cross-talk isolation: < -70 dB (between adjacent lines); EMI/RFI compliance: CISPR 22 Class A |

| Safety & Compliance | CE, FCC Class A, UL 61010-1, IEC 61010-1; Overvoltage protection: ±15 V (input lines); Short-circuit protection: Per-port current limiting |

| Additional Features | Per-port LED indicators (I/O activity, error status); Software-configurable pull-up/pull-down resistors (10 kΩ); Supports pattern generation, edge detection, and state monitoring |

| Included Accessories | 2× 200-pin SCSI-II breakout cables (1 m length); Terminal block adapter (for easy sensor wiring); NI-DAQmx driver CD; Quick start guide |

Product introduction

The NI PCI-3840 is a high-density PCI digital I/O module developed by National Instruments (NI), engineered to deliver 384 bidirectional digital lines for industrial automation, high-volume test, and embedded system validation—addressing critical needs for parallel signal control that serial modules like the NI PXI-8423 (focused on RS-232/RS-485) cannot fulfill. Unlike low-channel digital I/O cards (typically 16–64 lines), the NI PCI-3840 acts as a “digital signal hub” for PCI-based systems, enabling simultaneous control and monitoring of hundreds of digital signals—essential for applications like semiconductor wafer testing, industrial machine I/O expansion, and DUT pin stimulation.

As a flagship model in NI’s high-density digital I/O lineup, the NI PCI-3840 excels in scenarios requiring massive parallelism. For example, a consumer electronics manufacturer uses the NI PCI-3840 in a smartphone PCB test rig: 256 lines stimulate PCB test points (e.g., power rails, data pins), while 128 lines monitor response signals (e.g., LED status, button presses) to verify functionality. Unlike the NI PXI-8423, which handles serial communication, the NI PCI-3840 processes hundreds of digital signals in parallel with 10 MHz burst update rates—reducing test time per PCB by 70% compared to low-channel cards. Whether used in high-volume manufacturing, aerospace avionics testing, or industrial control, the NI PCI-3840 delivers the density and speed needed for demanding digital workflows.

Core advantages and technical highlights

384-Channel Density for Massive Parallel I/O: The NI PCI-3840’s 384 bidirectional lines (organized into 12 ports) enable control of hundreds of digital signals—far beyond low-channel alternatives (e.g., 64-line cards). A semiconductor test lab leverages this to test 8 microcontroller units (MCUs) simultaneously: each MCU requires 48 digital lines (24 input, 24 output), and the NI PCI-3840 handles all 384 lines via a single PCI slot—eliminating the need for 6 low-channel cards and reducing PC slot usage by 83%. This density is critical for high-volume testing, where minimizing hardware footprint and simplifying wiring directly impacts production throughput.

10 MHz Burst Update Rate for High-Speed Signaling: The NI PCI-3840 supports 10 MHz burst update rates—enabling fast pattern generation and state monitoring for time-sensitive applications. An aerospace lab uses the module to simulate avionics bus signals (e.g., ARINC 429 discrete signals) at 5 MHz: the NI PCI-3840 generates synchronized digital patterns to test avionics hardware, with 20 ns propagation delay ensuring signal alignment with other test instruments (e.g., NI PXIe-5122 digitizers). This speed surpasses low-channel digital cards (typically limited to 1 MHz) and ensures compliance with strict aerospace test standards (e.g., RTCA DO-160).

DMA Data Transfer for Low-CPU Overhead: The NI PCI-3840 uses scatter-gather DMA to offload digital I/O data transfer from the host CPU—critical for maintaining high update rates without bottlenecking system performance. A car infotainment test facility uses the module to monitor 384 digital status signals (e.g., touchscreen inputs, speaker enable lines) at 1 MHz continuous rate: DMA transfers raw data to system memory, leaving the CPU free to run test analysis software (e.g., LabVIEW-based pass/fail logic). Without DMA, the CPU would be overwhelmed by I/O interrupts, causing data loss and test inaccuracies—issues avoided by the NI PCI-3840.

Per-Line Configurability for Versatile Use Cases: The NI PCI-3840 supports software-configurable per-line direction (input/output), pull-up/pull-down resistors (10 kΩ), and ±24 mA output drive current—enabling compatibility with diverse digital devices (e.g., TTL sensors, CMOS ICs, industrial relays). A robotics manufacturer uses this flexibility to control 128 relay outputs (for motor drivers) and monitor 256 limit switch inputs: relay lines are configured as 5 V outputs with 24 mA drive current, while switch lines use pull-up resistors to avoid floating signals. This versatility eliminates the need for external signal conditioners, simplifying system design and reducing costs compared to fixed-function digital cards.

Typical application scenarios

In high-volume automotive electronics testing, a manufacturer uses the NI PCI-3840 to validate 10 automotive ECU (Electronic Control Unit) PCBs simultaneously. Each ECU requires 38 digital lines (18 input, 20 output) for functions like sensor simulation (e.g., throttle position) and status monitoring (e.g., fault LEDs). The NI PCI-3840 connects to a breakout terminal block, which routes 384 lines to 10 ECU test fixtures. The module runs at 2 MHz continuous update rate, generating sensor signals and logging ECU responses via DMA—reducing test time per ECU from 2 minutes to 18 seconds. The NI PCI-3840’s per-line configurability lets engineers adjust I/O direction for different ECU models, and its short-circuit protection prevents damage if an ECU pin is shorted to ground—critical for 24/7 manufacturing environments.

In aerospace avionics testing, a defense contractor uses the NI PCI-3840 to simulate discrete digital signals for a fighter jet’s flight control system. The module generates 256 digital command signals (e.g., aileron trim, landing gear enable) at 5 MHz burst rate, while 128 lines monitor system responses (e.g., fault flags, position feedback). The NI PCI-3840 synchronizes with a NI PXI-8423 (serial communication) via LabVIEW: the NI PCI-3840 handles parallel digital I/O, while the NI PXI-8423 communicates with a flight control computer via RS-485. This setup meets MIL-STD-883 requirements for signal integrity, with the NI PCI-3840’s ESD protection (±15 kV) ensuring reliability in harsh test environments.

Related model recommendations

NI PCIe-6535: PCIe digital I/O module that upgrades the NI PCI-3840—offers 320 channels, 100 MHz update rate, and PCIe x1 connectivity for users migrating to modern PCIe systems.

NI PXI-6534: PXI digital I/O module complementary to the NI PCI-3840—256 channels, 40 MHz update rate, ideal for mixed PXI/PCI systems (e.g., combining with NI PXI-8423 for serial I/O).

NI TB-2715: 384-channel terminal block for the NI PCI-3840—breaks out SCSI-II connectors to accessible screw terminals, simplifying wiring of sensors, relays, and DUTs.

NI-DAQmx Driver: Core software for the NI PCI-3840—enables per-line configuration (direction, pull-up resistors), DMA setup, and integration with LabVIEW/C/C++/Python.

NI LabVIEW 2024: Programming software for the NI PCI-3840—includes pre-built VIs for pattern generation, edge detection, and state monitoring, reducing test application development time by 40%.

NI TestStand 2024: Automated test management software that works with the NI PCI-3840—creates step-by-step test sequences (e.g., ECU validation) and generates compliance reports.

NI PCI-3820: 192-channel PCI digital I/O module alternative to the NI PCI-3840—for users with fewer I/O needs (e.g., 100–200 lines), reducing cost while retaining core features.

NI PXIe-1085: PXIe hybrid chassis compatible with the NI PCI-3840 (via PCI slot adapter)—enables mixing the NI PCI-3840 with modern PXIe instruments (e.g., NI PXIe-4143 SMUs) for mixed-signal testing.

NI SCXI-1000: Legacy SCXI chassis that complements the NI PCI-3840—the NI PCI-3840 handles digital I/O, while the NI SCXI-1000 (with NI SCXI-1193) manages analog sensor wiring for mixed-signal systems.

NI 200-pin SCSI-II Cable (185030-01): Spare cable for the NI PCI-3840—replaces included breakout cables if damaged, ensuring reliable connectivity to terminal blocks or DUTs.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PCI-3840, power off the host PC and wear an ESD wristband (±15 kV) to protect the module’s digital circuitry. Ensure the PC has an available PCI slot (32-bit/33 MHz or PCI-X) and remove the corresponding slot cover. Align the NI PCI-3840’s gold fingers with the PCI slot, press firmly until the module seats fully, then secure it with the slot screw. Connect the included 200-pin SCSI-II breakout cables to the module’s front-panel connectors and route them to a terminal block (e.g., NI TB-2715) for sensor/DUT wiring. Power on the PC, install the latest NI-DAQmx driver and LabVIEW, and use NI Measurement & Automation Explorer (MAX) to detect the NI PCI-3840.

Commissioning and maintenance: Run a “Digital I/O Self-Test” in MAX to verify functionality: configure 16 lines as output (set to logic high), 16 lines as input, and cross-connect them to confirm signal detection. Calibrate the module annually using a NIST-traceable digital pattern generator to verify timing performance (e.g., setup/hold time, propagation delay). Inspect the NI PCI-3840 quarterly: check SCSI-II connectors for bent pins or corrosion (clean with isopropyl alcohol, 99.9% purity), and verify LED indicators (activity LEDs should match I/O traffic). If the module experiences data loss, update the NI-DAQmx driver or check for PCI bus conflicts (resolve via PC BIOS settings). Avoid exposing the NI PCI-3840 to temperatures above 55 °C or humidity above 90%—extreme conditions can degrade digital line drivers. Store spare modules in anti-static bags to prevent ESD damage.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for new NI PCI-3840 units (90 days for refurbished units), covering defects in the digital line drivers, PCI interface, and SCSI-II connectors. For extended support, the NI ServicePlus Premium Plan offers 4-year coverage, including annual factory calibration (traceable to NIST) for timing and signal integrity, priority technical support (2-hour response time for manufacturing/aerospace customers), and expedited repairs (turnaround time < 3 business days).

NI’s global technical team includes digital I/O specialists, offering 24/7 support for the NI PCI-3840—assisting with DMA configuration, high-speed pattern generation, and troubleshooting of digital signal errors. Customers gain free access to exclusive resources: application notes on semiconductor testing with the NI PCI-3840, LabVIEW example code for parallel I/O control, and a user community for sharing high-density digital best practices. For out-of-warranty repairs, NI’s Precision Digital I/O Restore Service replaces aged components (digital transceivers, PCI bus controllers) and verifies timing/voltage performance—restoring the NI PCI-3840 to factory specifications. This commitment reflects NI’s confidence in the module’s durability and dedication to supporting users’ long-term high-density digital I/O needs.