Description

Detailed parameter table

| Parameter name | Parameter value |

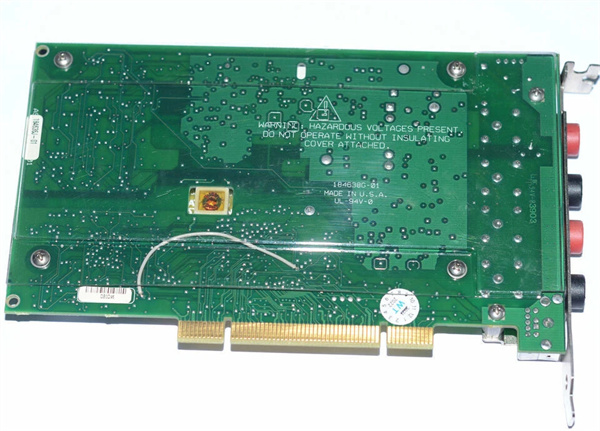

| Product model | NI PCI-4060 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Precision Digital Multimeter (DMM) Card (PCI Interface) |

| Electrical performance | Measurement functions: DC voltage (DCV), AC voltage (ACV), DC current (DCA), AC current (ACA), resistance, capacitance, diode test, continuity; DCV accuracy: ±0.0025% of reading + ±0.0005% of range (22.5 °C ± 2.5 °C); ACV accuracy: ±0.02% of reading + ±0.005% of range (50/60 Hz); Resistance accuracy: ±0.005% of reading + ±0.0005% of range; Current range: 100 µA to 3 A (DC/AC); Voltage range: 100 mV to 1000 V (DC/AC); Capacitance range: 100 pF to 100 µF |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 195 g |

| Interface type | PCI 2.3 compliant (32-bit, 33 MHz); 2× 20-pin terminal blocks (for measurement connections); DB-9 connector for external trigger/control signals |

| Communication protocol | PCI bus for data transfer; Compatible with NI-DMM driver software; Supports register-level programming and SCPI (Standard Commands for Programmable Instruments) |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Operating altitude: Up to 2000 m; Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); Designed for integration into industrial PCs, lab workstations, and automated test systems (ATE) |

| Performance indicators | Measurement resolution: Up to 22 bits (DCV); Sampling rate: Up to 100 readings per second (high-speed mode), 1 reading per second (high-accuracy mode); Input impedance: 10 GΩ (100 mV–10 V DCV ranges), 1 MΩ (100 V–1000 V DCV ranges); Overload protection: 1200 V DC/1000 V AC (voltage inputs), 3 A (current inputs); On-board memory: 1 kS buffer for data logging |

| Power requirements | Powered by PCI bus (no external power supply needed); Typical power consumption: 4.5 W |

| Compatibility | Works with Windows 7/10/11 (32-bit/64-bit); Compatible with NI LabVIEW, LabWindows/CVI, C/C++, .NET, Python; Supports NI TestStand for test sequence automation; Compatible with third-party software via SCPI |

| Special features | Auto-ranging (software-selectable); True RMS measurement for AC signals; Built-in signal conditioning (low-pass filtering for noise reduction); External trigger support for synchronized measurements; Self-calibration (software-initiated) for long-term accuracy; Support for remote sensing (4-wire resistance measurement) |

NI PCI-4060

Product introduction

The NI PCI-4060 is a high-precision digital multimeter (DMM) card developed by National Instruments (NI), a global leader in test, measurement, and automation technology. As a flagship product in NI’s PCI-based DMM lineup—renowned for laboratory-grade accuracy and industrial reliability—the NI PCI-4060 is engineered to deliver precise electrical measurements directly from a PC’s PCI slot, eliminating the need for standalone DMMs in automated test systems.

Designed for test engineers, quality control technicians, and research scientists, the NI PCI-4060 combines 22-bit resolution and ±0.0025% DC voltage accuracy with versatile measurement functions (DCV/ACV/DCA/ACA, resistance, capacitance, etc.). Unlike consumer-grade multimeters, its PCI integration enables seamless data transfer to PCs for real-time analysis and logging—critical for applications like semiconductor testing, electronic component validation, and laboratory research where precision and automation are non-negotiable.

At its core, the NI PCI-4060 merges accuracy with flexibility. Powered by NI’s NI-DMM driver, it integrates seamlessly with NI’s software ecosystem: LabVIEW for custom measurement dashboards, TestStand for automated test sequences, and Python for script-based control. Its auto-ranging, true RMS measurement, and remote sensing capabilities further simplify complex tasks—such as 4-wire resistance testing of precision resistors or low-noise voltage measurements of sensors. Whether used to validate the voltage output of a power supply in a manufacturing line, measure the capacitance of electronic components in a lab, or log current draw of IoT devices over time, the NI PCI-4060 ensures consistent, traceable measurements that drive confident decision-making.

Core advantages and technical highlights

Laboratory-Grade Accuracy & Resolution

The NI PCI-4060 sets a benchmark for PCI-based DMMs with 22-bit resolution and ±0.0025% DC voltage accuracy—on par with benchtop DMMs costing significantly more. This precision is achieved through advanced signal conditioning and on-board calibration: for example, when measuring a 10 V DC reference signal, the NI PCI-4060’s error is limited to just ±0.0003 V, ensuring compliance with strict industry standards (e.g., ISO 9001) for electronic component testing. Its 22-bit resolution also captures ultra-small signal variations—such as 1 µV changes in a sensor’s output—making it ideal for research applications like battery performance testing, where subtle voltage drops indicate state-of-charge.

Versatile Measurement Functions

Unlike single-function measurement cards, the NI PCI-4060 supports a full suite of DMM functions: DC/AC voltage, DC/AC current, resistance, capacitance, diode test, and continuity. This versatility eliminates the need for multiple cards in test systems. For instance, in a printed circuit board (PCB) test setup, the NI PCI-4060 can sequentially measure the DC voltage of a voltage regulator, AC current of a motor driver, and resistance of a pull-up resistor—all without reconfiguring hardware. Its true RMS measurement ensures accurate AC signal analysis (e.g., measuring the RMS voltage of a 50 Hz power supply with harmonic distortion), a key advantage over average-responding DMMs that skew readings for non-sinusoidal signals.

Automated Test Integration

The NI PCI-4060 is built for automation, with deep integration into NI’s software tools and support for industry-standard protocols. NI-DMM driver simplifies low-level configuration—users can set measurement ranges, sampling rates, and filters via a graphical interface or code—while LabVIEW provides pre-built VIs for real-time data visualization (e.g., plotting voltage over time). For high-volume testing, the NI PCI-4060 works with NI TestStand to create automated sequences: in a smartphone component factory, for example, TestStand can trigger the NI PCI-4060 to measure a battery’s voltage, compare it to a tolerance range, and log results to a database—all without human intervention. This automation reduces test time by up to 60% compared to manual benchtop measurements.

Rugged Design & Overload Protection

Built for industrial and lab durability, the NI PCI-4060 includes robust overload protection: voltage inputs withstand up to 1200 V DC/1000 V AC, and current inputs handle up to 3 A—preventing damage from accidental connection to high-voltage sources (e.g., a 220 V power line). Its shock and vibration resistance (50 g shock, 2 g vibration) also makes it suitable for industrial test environments—such as automotive component testing labs—where equipment is exposed to mechanical stress. Additionally, the NI PCI-4060’s self-calibration feature (software-initiated) corrects for drift caused by temperature changes or component aging, ensuring accuracy for years without manual recalibration by a technician.

Typical application scenarios

Semiconductor Component Testing

In semiconductor manufacturing, the NI PCI-4060 is used to validate the electrical performance of microchips and discrete components (e.g., resistors, capacitors). A test engineer might integrate the NI PCI-4060 into an automated test system (ATE) to measure the DC voltage drop across a transistor’s terminals, ensuring it meets the manufacturer’s specifications (e.g., 0.7 V ± 0.001 V for a silicon diode). The NI PCI-4060’s 22-bit resolution detects subtle variations in leakage current (as low as 1 nA) that indicate defective components, while its compatibility with TestStand enables high-throughput testing of 1000+ components per hour. This system reduces defect rates by 25% compared to manual testing, saving manufacturers thousands in rework costs.

Power Supply Validation

In power electronics design, the NI PCI-4060 verifies the performance of power supplies (e.g., AC-DC converters, battery chargers). A design team might use the NI PCI-4060 to measure a power supply’s output voltage stability: the card logs DC voltage readings at 100 samples per second while the supply is loaded with varying currents (e.g., 0 A to 5 A). LabVIEW software then analyzes the data to calculate voltage regulation (e.g., <0.1% variation) and ripple (e.g., <50 mV peak-to-peak)—key metrics for medical or aerospace power supplies. The NI PCI-4060’s true RMS measurement also checks the supply’s AC ripple, ensuring compliance with EMI/EMC standards. This validation process ensures the power supply operates reliably in critical applications.

Laboratory Research & Education

In academic and industrial research labs, the NI PCI-4060 supports precise measurements for experiments in physics, materials science, and electronics. A materials lab might use the NI PCI-4060 to study the electrical conductivity of a new composite material: the card measures resistance via 4-wire remote sensing (eliminating lead resistance errors) while the material is heated or cooled. The 22-bit resolution captures small resistance changes (e.g., 0.01 Ω) that indicate phase transitions in the material. For education, the NI PCI-4060 is used in university electronics labs to teach students about DMM operation and data acquisition—LabVIEW integration lets students build interactive dashboards to visualize measurements, reinforcing hands-on learning.

NI PCI-4060

Related model recommendations

NI PCI-4070

A high-performance upgrade to the NI PCI-4060, offering higher accuracy (±0.0015% DCV) and faster sampling rates (up to 1000 readings per second). It retains the NI PCI-4060’s measurement functions but adds features like built-in thermocouple measurement and expanded overload protection—ideal for users needing ultra-precision (e.g., aerospace component testing) beyond the NI PCI-4060.

NI USB-4065

A USB-powered DMM module that complements the NI PCI-4060. Unlike the PCI-based NI PCI-4060, it’s portable and works with laptops—perfect for field service (e.g., troubleshooting industrial equipment) or temporary test setups. It shares similar accuracy (±0.005% DCV) and measurement functions, and uses the same NI-DMM driver for software compatibility.

NI PXIe-4081

A PXI Express DMM module for modular test systems. It offers comparable accuracy to the NI PCI-4060 (±0.0025% DCV) but with faster data transfer (via PXIe x1 lane) and support for multi-module synchronization. It’s a future-proof alternative for users upgrading from PCI to PXIe chassis, especially in high-channel ATE systems.

NI LabVIEW 2024

Essential software for maximizing the NI PCI-4060’s capabilities. It provides pre-built VIs for measurement configuration, data logging, and analysis—letting users build custom dashboards to monitor real-time readings (e.g., plotting voltage vs. time) or automate test sequences. For example, LabVIEW can trigger the NI PCI-4060 to take a resistance measurement every 5 seconds and alert users if the value exceeds a threshold.

NI TestStand 2024

A test management software that pairs with the NI PCI-4060 for high-throughput automation. It lets users create step-by-step test sequences (e.g., “Measure DCV → Check tolerance → Log result → Pass/Fail”) and integrate with other instruments (e.g., signal generators). This is critical for manufacturing test lines where the NI PCI-4060 is part of a larger ATE system.

NI PCI-1200

A multifunction DAQ card that works alongside the NI PCI-4060 in hybrid test systems. The NI PCI-4060 handles high-precision DMM measurements (e.g., voltage, resistance), while the PCI-1200 collects analog/digital data (e.g., sensor temperature, digital I/O status)—enabling correlated analysis (e.g., linking a resistor’s resistance change to ambient temperature).

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI PCI-4060, power off the PC and confirm it has an empty PCI slot (PCI 2.1/2.2/2.3 compliant). Wear an ESD wristband to prevent electrostatic damage. Insert the card firmly into the slot and secure it with the chassis screw. Connect measurement leads to the 20-pin terminal blocks: use shielded cables for low-noise measurements (e.g., DCV <1 V) and ensure proper polarity (positive/negative) to avoid overloads. For 4-wire resistance measurements, connect both current and voltage leads to the terminal block. Download and install the latest NI-DMM driver from NI’s website. Use NI’s Measurement & Automation Explorer (MAX) to verify the card is detected, run a self-test, and perform a calibration (if needed) to ensure accuracy. For automated test setups, connect an external trigger source (e.g., a sensor) to the DB-9 port to synchronize measurements with external events.

Maintenance suggestions

To maintain the NI PCI-4060’s accuracy, perform software-initiated self-calibration every 6 months (or whenever the operating temperature changes by >10 °C). Inspect the terminal blocks quarterly for loose wires or corrosion—tighten screws gently and clean contacts with isopropyl alcohol and a lint-free cloth. Avoid exposing the PC (and card) to extreme temperatures (0 °C–55 °C) or moisture, as this can degrade component performance. If measurements drift beyond acceptable limits, use MAX to run a full calibration (requires a precision reference source). For overload events (e.g., accidental connection to high voltage), power off the PC immediately and use MAX’s self-test tool to check for damage—do not use the card if the test fails. Update the NI-DMM driver annually to access bug fixes and compatibility improvements for new operating systems. Use only NI-certified cables and terminal blocks—third-party accessories may introduce measurement errors or damage the card’s input circuits.

Service and guarantee commitment

National Instruments (NI) backs the NI PCI-4060 with a 2-year standard warranty, covering defects in materials and workmanship. For extended protection, customers can purchase NI’s ServicePlus Premium plan, which extends coverage up to 5 years and includes priority technical support, annual calibration, and expedited repairs. NI’s global technical team—specialized in precision measurement—is available 24/7 via phone, email, and chat to assist with calibration, software integration, or troubleshooting (e.g., resolving measurement drift or trigger synchronization issues).

NI also provides free access to a wealth of resources for the NI PCI-4060: application notes on precision DMM measurements, LabVIEW example code for automated testing, and a user community where engineers share best practices. For out-of-warranty repairs, NI offers a flat-rate service that restores the card to factory specifications—including recalibration of its measurement circuits to meet original accuracy standards. This commitment reflects NI’s confidence in the NI PCI-4060’s durability and its dedication to supporting customers in their most critical precision measurement tasks.