Description

NI SCXI-1000 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | SCXI-1000 |

| Manufacturer | National Instruments (NI) |

| Product category | Signal conditioning chassis |

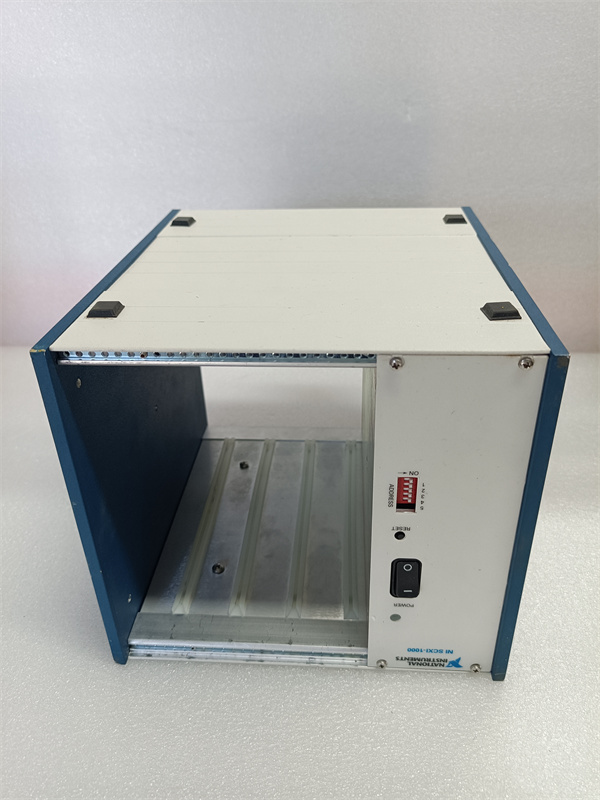

| Slots | 10 slots for module insertion |

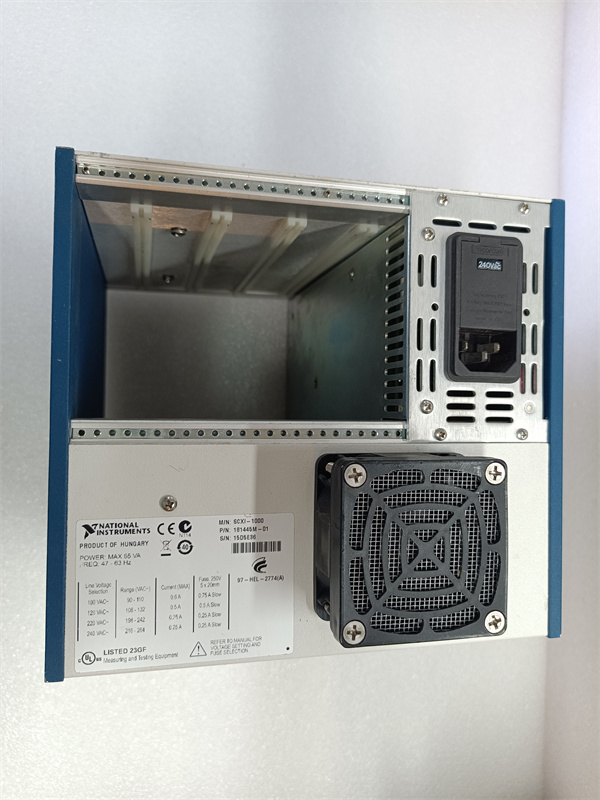

| Power supply | Supports 100 – 240 VAC, 50/60 Hz input |

| Dimensions | 17.78 cm (H) x 48.26 cm (W) x 40.64 cm (D) |

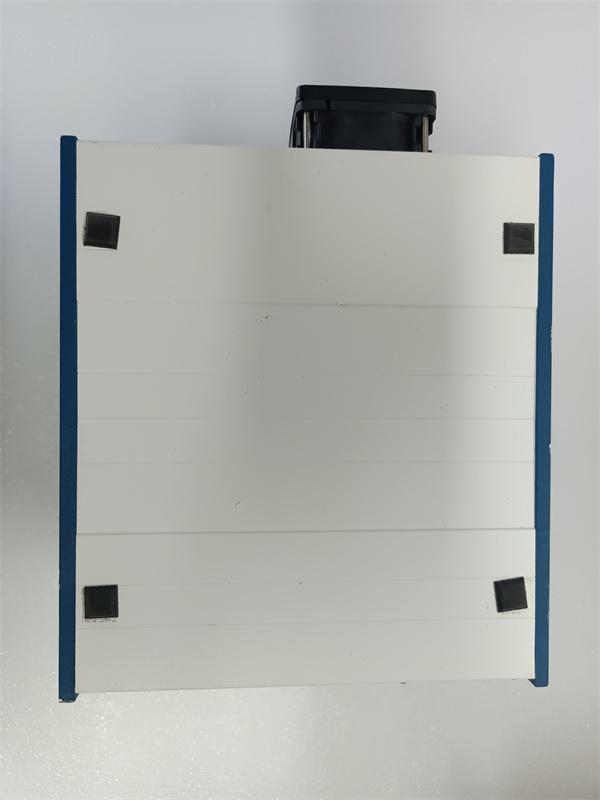

| Cooling method | Forced – air cooling |

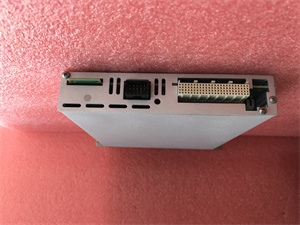

| Communication interface | SCXI bus for connecting modules, and Ethernet for system – level communication |

| Operating temperature | 0 °C to 55 °C |

| Storage temperature | – 40 °C to 70 °C |

| Weight | Approximately 12.7 kg |

| Maximum power consumption | Varies based on installed modules, up to a specified limit |

NI SCXI-1000

Product introduction

The NI SCXI-1000 is a versatile and robust signal conditioning chassis developed by National Instruments (NI), a leading force in the test, measurement, and automation industry. As the foundation of the SCXI (Signal Conditioning eXtensions for Instrumentation) platform, the SCXI-1000 provides the essential infrastructure for building comprehensive data acquisition and control systems.

Featuring 10 slots, the NI SCXI-1000 can house a variety of SCXI modules, such as signal conditioning modules, input/output modules, and more. This modular design allows users to customize their systems according to specific application requirements. With support for a wide – range 100 – 240 VAC power input, it can be deployed in diverse geographical locations and industrial settings. The chassis uses forced – air cooling to ensure stable operation of the installed modules, even under heavy workloads. Its Ethernet communication interface enables seamless integration with other NI systems and external devices, facilitating efficient data transfer and system – level control. Whether in industrial automation, research laboratories, or product testing environments, the SCXI-1000 serves as a reliable and flexible platform for signal conditioning and data acquisition.

Core advantages and technical highlights

Highly Modular Design: The NI SCXI-1000‘s 10 – slot architecture offers unparalleled flexibility. Users can mix and match different SCXI modules, like the signal conditioning modules for specific sensor types or input/output modules for controlling actuators. This modularity allows for easy system expansion and customization. For example, in a complex industrial monitoring project, additional modules can be added to the SCXI-1000 as the measurement requirements grow, without the need to replace the entire system.

Reliable Power and Cooling: The wide – range power supply support of the SCXI-1000 ensures compatibility with various electrical grids around the world. The forced – air cooling system effectively dissipates heat generated by the installed modules, preventing overheating and ensuring continuous and stable operation. This reliability is crucial in industrial environments where uninterrupted data acquisition is essential for process control and quality monitoring.

Efficient Communication Capabilities: The combination of the SCXI bus for internal module communication and the Ethernet interface for system – level communication gives the NI SCXI-1000 excellent connectivity. The SCXI bus enables fast and reliable data transfer between modules, while the Ethernet interface allows for seamless integration with PCs, network – based control systems, and other external devices. This enables real – time data sharing, remote monitoring, and control, enhancing the overall efficiency of the measurement and automation system.

Robust Build Quality: Built to withstand the rigors of industrial and laboratory use, the SCXI-1000 has a durable construction. Its metal enclosure provides protection against physical damage, electromagnetic interference, and dust. The chassis is designed to meet strict industry – standard environmental requirements, ensuring reliable operation in a wide range of operating conditions.

NI SCXI-1000

Typical application scenarios

In industrial manufacturing, the NI SCXI-1000 is widely used for process monitoring and control. In a large – scale automotive assembly plant, it can house signal conditioning modules that interface with sensors measuring parameters like torque, position, and vibration of various production equipment. The Ethernet connectivity of the SCXI-1000 allows the collected data to be sent to a central control system in real – time, enabling operators to monitor the production process, detect anomalies, and make adjustments promptly to ensure product quality and production efficiency.

In research laboratories, especially those focused on physics, chemistry, and biology, the SCXI-1000 provides a flexible platform for experimental data acquisition. Scientists can install different types of signal conditioning modules in the SCXI-1000 to interface with sensors used in experiments, such as measuring electrical signals from biological cells or chemical reactions. The modular design and high – precision signal conditioning capabilities of the system enable accurate and reliable data collection, which is essential for scientific research and discovery.

In the aerospace industry, the SCXI-1000 is used for testing and validating aircraft components. It can be configured with modules to condition signals from sensors placed on engines, wings, and other critical parts during ground testing. The reliable operation and efficient data transfer capabilities of the SCXI-1000 ensure that the test data is accurate and can be analyzed in a timely manner, helping engineers to optimize aircraft design and improve safety.

Related model recommendations

- NI SCXI-1125: A high – density signal conditioning module that can be installed in the SCXI-1000. It offers a large number of input channels, making it suitable for applications that require extensive simultaneous measurements. When combined with the SCXI-1000, it expands the system’s measurement capacity, ideal for large – scale industrial monitoring projects.

- NI SCXI-1122: Specialized for strain – gage and bridge measurements, this module provides accurate signal conditioning for these types of sensors. Installing the SCXI-1122in the SCXI-1000 enables users to perform precise strain and stress measurements, which is crucial in structural health monitoring and material testing applications.

- NI SCXI-1163R: A signal conditioning module with 8 differential or 16 single – ended input channels. It can handle a wide range of analog signals and is suitable for various general – purpose measurement applications. When placed in the SCXI-1000, it adds flexibility to the system, allowing for the integration of different sensor types.

- NI SCXI-1300: A terminal block accessory for the SCXI platform. It simplifies the connection of external sensors and devices to the modules installed in the SCXI-1000. By providing an organized and user – friendly wiring interface, it enhances the usability and reliability of the overall measurement system.

- NI SCXI-1140: A high – accuracy differential input module. It offers superior precision in signal conditioning, making it suitable for applications that demand extremely accurate measurements, such as calibration laboratories. Installing the SCXI-1140in the SCXI-1000 can improve the overall accuracy of the measurement system when dealing with critical data acquisition tasks.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI SCXI-1000, choose a suitable location that meets the environmental requirements, such as appropriate temperature and humidity levels, and is free from excessive dust and electromagnetic interference. Ensure that the power source available at the installation site is within the supported 100 – 240 VAC range. Use proper lifting equipment if needed, as the chassis weighs approximately 12.7 kg. When inserting modules into the SCXI-1000, make sure to align them correctly with the slots and firmly seat them to ensure proper electrical connections. Also, ensure that all Ethernet and other communication cables are properly connected and secured.

Maintenance suggestions: Regularly check the status indicators on the SCXI-1000 to monitor its operation. Clean the air vents of the chassis regularly to prevent dust accumulation, which can affect the cooling efficiency. Periodically inspect the power supply connections and communication cables for any signs of damage. In case of any abnormal behavior, such as unexpected shutdowns or communication errors, first check the module connections and configuration settings. If the problem persists, refer to the troubleshooting guide in the product manual. When replacing modules or components, always use genuine NI parts to ensure compatibility and maintain the system’s performance.

Service and guarantee commitment

We have full confidence in the quality and reliability of the NI SCXI-1000. The product comes with a comprehensive warranty that covers any manufacturing defects. During the warranty period, if the chassis fails to function as specified, we will repair or replace it free of charge. Our dedicated technical support team is available around – the – clock to assist customers with installation, commissioning, and any technical issues. We offer a wide range of online resources, including detailed user manuals, software drivers, and application notes, to help users make the most of the SCXI-1000. Additionally, we are committed to continuous product improvement and regularly release firmware updates to enhance the functionality and compatibility of the chassis, ensuring that our customers’ measurement and automation systems remain at the forefront of technology.