Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | NI PCI-5911 |

| Manufacturer | National Instruments (NI) |

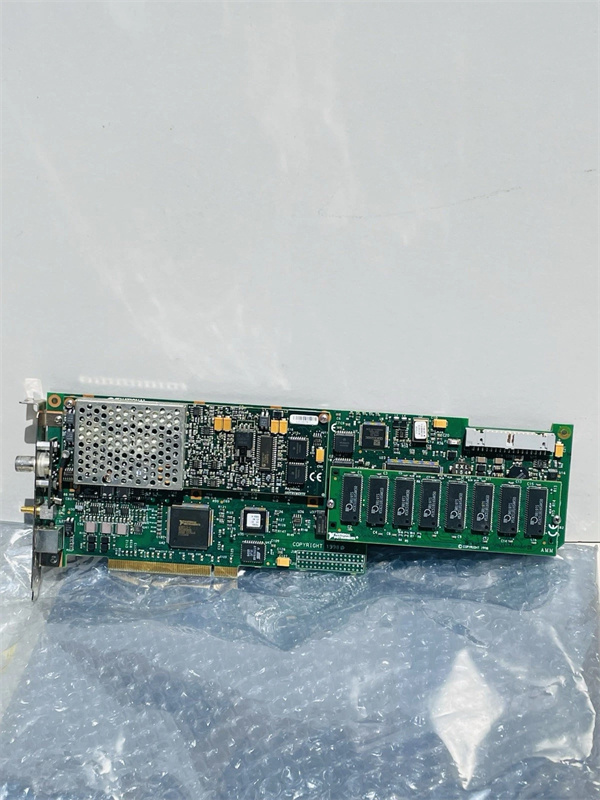

| Product category | High-Speed Digitizer Card (PCI Interface) |

| Electrical performance | Channels: 1 flexible resolution channel; Resolution: 8 bits at 100 MS/s, 21 bits at 10 KS/s; Sampling rate: 100 MS/s real – time, 1 GS/s random – interleaved sampling (for repetitive signals in conventional mode); Bandwidth: 100 MHz; Waveform memory: 4 MB or 16 MB (deep, integrated, with multi – record capture mode); Input voltage range: Programmable, suitable for various signal levels; Noise and distortion: Low noise and low distortion for high – quality signal acquisition |

| Physical size | Dimensions (L×W×H): Approximately 33.78 cm × 9.91 cm (13.3 x 3.9 in.); Weight: N/A (not specified in common sources) |

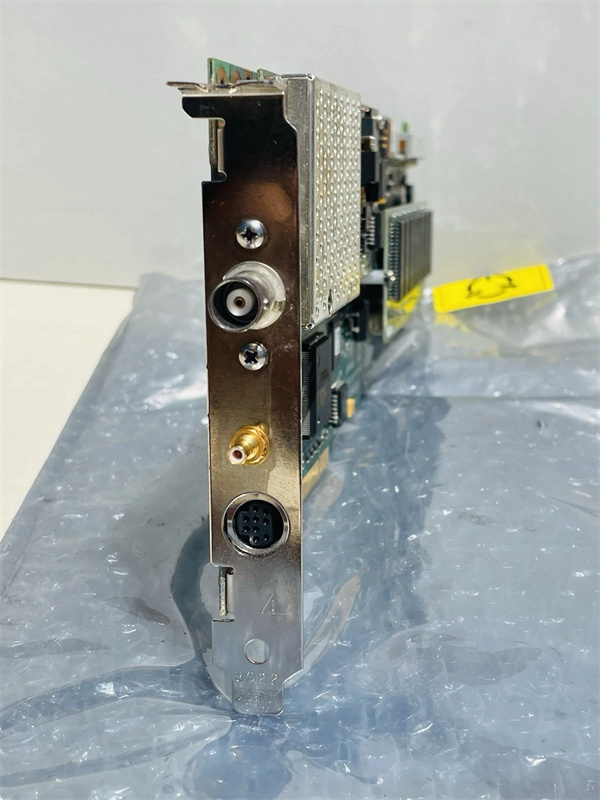

| Interface type | PCI interface (compatible with relevant PCI standards); Front panel connectors: 1 BNC, 1 SMB, 1 9 – pin mini – circular DIN connector |

| Communication protocol | PCI bus for data transfer; Compatible with NI – SCOPE instrument driver; Supports communication with software packages such as LabVIEW, Measurement Studio, Microsoft C++, Microsoft Visual Basic |

| Environmental requirements | Operating temperature: 5 °C to 40 °C; Storage temperature: – 20 °C to 65 °C; Relative humidity: N/A (not specified in common sources); Operating altitude: N/A (not specified in common sources); Vibration resistance: N/A (not specified in common sources); Shock resistance: N/A (not specified in common sources) |

| Installation method | Standard PCI slot mounting (compatible with appropriate PCI – compliant chassis); Installation process involves inserting the card into an available PCI slot, connecting relevant cables (such as signal cables to BNC or SMB connectors), and installing the NI – SCOPE driver software |

| Performance indicators | Acquisition modes: Conventional mode (8 – bit, 100 MHz digitizer for signals with 4 – 100 MHz bandwidths) and flexible – resolution mode (extends effective resolution beyond 8 bits for signals with less than 4 MHz bandwidths using patented signal processing technology); Anti – alias protection: Provided for flexible – resolution sampling mode; Trigger sources: Software, analog, and digital control. Analog trigger from threshold comparison, digital trigger from external digital connectors or RTSI bus; Clock generator: 100 MHz advanced clock generator for easy synchronization of multiple devices |

| Power requirements | +5 VDC, +12 VDC, -12 VDC with current requirements of 4 A, 100 mA, 100 mA respectively |

| Compatibility | Works with compatible Windows operating systems (note that support for some older systems like Windows 7 (32 – and 64 – bit), Windows Server 2008 R2, and all 32 – bit Windows operating systems was dropped in 2021 for relevant NI – SCOPE versions); Compatible with NI LabVIEW, Measurement Studio, C/C++, Visual Basic; Supports NI – SCOPE driver – related functionality for data acquisition and control |

| Special features | Scatter – gather capability for data rates faster than RS – 232 and GPIB, which can reduce overall test time; Warm – up time of 15 minutes; Self – calibration available, but external calibration recommended at least once a year |

NI PCI-5911

Product introduction

The NI PCI – 5911 is a high – speed digitizer card developed by National Instruments (NI), a leading name in the field of test, measurement, and automation solutions. This card is designed to be installed in a PC’s PCI slot, enabling users to digitize high – frequency analog signals with remarkable precision and flexibility.

With its single flexible resolution channel, the NI PCI – 5911 can operate at 8 bits with a sampling rate of 100 MS/s for high – speed, wide – bandwidth applications, or it can switch to 21 – bit resolution at a lower sampling rate of 10 KS/s for scenarios that demand higher precision in measuring low – frequency or slow – changing signals. The 100 MHz bandwidth ensures that it can accurately capture and digitize signals across a broad range of frequencies, making it suitable for a wide variety of applications.

The integrated waveform memory, available in 4 MB or 16 MB capacities with multi – record capture mode, provides sufficient storage for acquired data. The card’s ability to perform both real – time sampling at 100 MS/s and random – interleaved sampling at 1 GS/s (for repetitive signals in conventional mode) further enhances its versatility, allowing it to meet the requirements of different types of signal acquisition tasks.

Core advantages and technical highlights

Flexible Resolution and Sampling Rates

The NI PCI – 5911 stands out with its unique ability to offer variable resolution and sampling rates. In conventional mode, it functions as an 8 – bit, 100 MHz digitizer, capable of real – time sampling at 100 MS/s and random – interleaved sampling at 1 GS/s for repetitive signals. This is extremely useful for applications such as high – speed data acquisition in communication systems, where capturing fast – changing signals accurately is crucial.

When dealing with signals having a bandwidth less than 4 MHz, the flexible – resolution mode comes into play. Using patented signal processing technology, this mode extends the effective resolution beyond 8 bits. The ADC circuitry acts as a multibit sigma – delta converter, sampling the signal at 100 MS/s. A noise – shaping circuit then moves quantization noise from lower to higher frequencies. After that, the data is linearized to a precision of 21 bits in a DSP, and a digital low – pass filter (which also serves as an anti – alias filter) removes the high – frequency noise. Finally, the data is resampled at a lower rate with a higher effective resolution. This flexibility allows for high – precision measurements in applications like sensor calibration, where accurate measurement of low – level signals is required.

Low Noise and Distortion Performance

The NI PCI – 5911 is engineered to provide low noise and low distortion performance. Whether it’s capturing transients, analyzing spectra, recording waveforms, or digitizing intermediate frequency signals (IFs), this digitizer ensures that the acquired data is of high quality. Low noise is particularly important in applications such as semiconductor test and component characterization. In semiconductor test, for example, when measuring the electrical characteristics of a microchip, any additional noise from the digitizer could lead to inaccurate readings and misinterpretation of the chip’s performance. The low distortion feature also guarantees that the digitized signal faithfully represents the original analog signal, which is essential for accurate signal analysis in research and development scenarios.

Scatter – Gather Capability

This digitizer capitalizes on the scatter – gather capability, which enables data rates faster than traditional interfaces like RS – 232 and GPIB. This feature has a significant impact on overall test time. In high – throughput test systems, where large amounts of data need to be transferred quickly between the digitizer and the host computer, the scatter – gather capability of the NI PCI – 5911 allows for more efficient data transfer. For instance, in an automated test system for electronic components, the faster data transfer rate reduces the time required to acquire and analyze data from each component, thereby increasing the overall productivity of the test system.

Advanced Clock Generator for Synchronization

The NI PCI – 5911 is equipped with a 100 MHz advanced clock generator. This feature is crucial for applications that require synchronization of multiple devices. In a multi – channel data acquisition system, for example, where several digitizers need to work in unison to capture different aspects of a complex signal, the advanced clock generator ensures that all the devices are precisely synchronized. This synchronization is essential for accurate signal reconstruction and analysis. In a radar system test, where the digitizer needs to synchronize with other instruments such as signal generators and analyzers, the 100 MHz clock generator enables seamless coordination, leading to more reliable test results.

Typical application scenarios

Component Characterization

In the field of component characterization, the NI PCI – 5911 is used to accurately measure the electrical properties of various electronic components. For example, when characterizing a high – speed amplifier, the digitizer can capture the amplifier’s output signal with high precision. The flexible resolution and sampling rates allow engineers to measure the amplifier’s gain, bandwidth, and distortion characteristics over a wide range of frequencies. The low noise and distortion performance of the NI PCI – 5911 ensure that the measured values accurately represent the true performance of the amplifier, without being affected by additional noise or distortion introduced by the measurement equipment.

Semiconductor Test

Semiconductor manufacturers rely on the NI PCI – 5911 for a variety of semiconductor test applications. When testing integrated circuits (ICs), the digitizer can be used to capture and analyze the electrical signals on the IC’s pins. The high – speed sampling capabilities are useful for testing high – speed serial interfaces in ICs, ensuring that the data transmission rates and signal integrity meet the required standards. In addition, the flexible – resolution mode can be used to measure the low – level signals associated with the leakage currents in semiconductor devices, which is crucial for evaluating the quality and reliability of the ICs.

Electronic Test

In general electronic test applications, the NI PCI – 5911 can be used to troubleshoot and debug electronic circuits. For example, in a printed circuit board (PCB) assembly line, the digitizer can be used to capture the signals on the PCB to identify any faulty components or incorrect signal traces. The ability to quickly capture and analyze signals using the high – speed sampling rates and the multi – record capture mode of the NI PCI – 5911 helps in reducing the time required to diagnose and fix problems, thereby improving the overall efficiency of the production process.

Video Test

The 100 MHz bandwidth of the NI PCI – 5911 makes it suitable for video test applications. When testing video signal processing components or systems, the digitizer can capture and analyze the video signals. For example, it can be used to measure the timing characteristics, signal levels, and distortion of analog video signals. In digital video systems, the NI PCI – 5911 can be used to capture and analyze the digital video data streams, ensuring that the video quality meets the required standards. The low noise and distortion performance are also important in video test applications, as any additional noise or distortion could affect the visual quality of the video.

NI PCI-5911

Related model recommendations

NI PCI – 5922

The NI PCI – 5922 is another high – speed digitizer from NI. It offers similar functionality to the NI PCI – 5911 but with some differences. It has multiple channels (unlike the single – channel NI PCI – 5911), which makes it suitable for applications that require simultaneous acquisition of multiple signals. For example, in a multi – sensor data acquisition system, where signals from different sensors need to be captured and analyzed simultaneously, the NI PCI – 5922 can be a better choice. It also has different resolution and sampling rate options, which may be more suitable for specific applications. If a user needs to acquire data from multiple channels with a different combination of resolution and sampling rates than what the NI PCI – 5911 offers, the NI PCI – 5922 could be considered.

NI PCI – 5122

The NI PCI – 5122 is a high – speed digitizer with 14 – bit resolution. It is a lower – cost option compared to the NI PCI – 5911 in some cases. If the application does not require the high – resolution capabilities of the NI PCI – 5911 (such as in applications where the signals have a relatively large dynamic range and a 14 – bit resolution is sufficient), the NI PCI – 5122 can be a viable alternative. It also has its own set of features, such as specific trigger options and data transfer capabilities, which may be suitable for certain types of applications. For example, in some industrial monitoring applications where the focus is on capturing relatively fast – changing signals with a moderate level of precision, the NI PCI – 5122 could meet the requirements at a more affordable price.

NI LabVIEW

NI LabVIEW is an essential software for maximizing the capabilities of the NI PCI – 5911. It provides a graphical programming environment that allows users to easily configure the digitizer, set up data acquisition parameters, and analyze the acquired data. With LabVIEW, users can create custom data acquisition and analysis applications tailored to their specific needs. For example, engineers can use LabVIEW to design a data acquisition system that continuously monitors and analyzes the signals captured by the NI PCI – 5911. They can also use LabVIEW’s built – in functions for signal processing, such as filtering, spectral analysis, and waveform generation, to further process and interpret the acquired data.

NI – SCOPE Software

The NI – SCOPE software is the instrument driver for the NI PCI – 5911. It provides the necessary interface between the hardware and the software applications. The NI – SCOPE software allows users to control the digitizer’s functions, such as setting the sampling rate, resolution, trigger conditions, and waveform memory settings. It also provides functions for data transfer, calibration, and error handling. Regular updates to the NI – SCOPE software ensure compatibility with the latest operating systems and hardware configurations, as well as improved performance and new features. For example, new versions of the software may include enhancements to the data transfer speed or additional calibration options for more accurate measurements.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI PCI – 5911, power off the PC and ensure that it has an available PCI slot that is compatible with the card. It is recommended to wear an electrostatic discharge (ESD) wristband to prevent any electrostatic damage to the card during installation. Insert the NI PCI – 5911 card firmly into the PCI slot and secure it with the appropriate chassis screw.

Connect the necessary cables to the front panel connectors of the card. The BNC and SMB connectors can be used to connect analog signal sources or measurement devices, depending on the application. The 9 – pin mini – circular DIN connector may be used for specific functions such as triggering or synchronization, depending on the setup.

Download and install the latest version of the NI – SCOPE driver software from the NI website. This software is essential for the proper functioning of the card and for communicating with other software applications. After installing the driver, use NI’s Measurement & Automation Explorer (MAX) to verify that the card is detected correctly. In MAX, you can also perform a self – test on the card to ensure that it is working properly.

Commissioning

Once the card is installed and the driver is installed and recognized by the system, you can start commissioning the NI PCI – 5911. Open the relevant software application, such as LabVIEW, and configure the digitizer settings according to your application requirements. This includes setting the sampling rate, resolution, input voltage range, trigger mode, and waveform memory settings.

For applications that require synchronization with other devices, configure the synchronization settings using the 100 MHz advanced clock generator and the appropriate trigger sources (software, analog, or digital). Test the data acquisition functionality by capturing a simple test signal and verifying that the acquired data is accurate and meets the expected specifications.

Maintenance suggestions

To maintain the optimal performance of the NI PCI – 5911, it is recommended to perform self – calibration regularly. Although the card has a self – calibration feature, external calibration is recommended at least once a year for the most accurate measurements. Check the front panel connectors periodically for any signs of corrosion or loose connections. If any issues are detected, clean the connectors with isopropyl alcohol and a lint – free cloth and tighten the connections as necessary.

Keep the PC and the card in an environment within the specified operating temperature range (5 °C to 40 °C) to ensure reliable operation. Avoid exposing the card to excessive humidity or extreme temperatures, as this can affect the performance and lifespan of the card. If the card experiences any issues, such as incorrect data acquisition or hardware failures, use the self – test and diagnostic functions available in the NI – SCOPE software or MAX to troubleshoot the problem. If the problem persists, contact NI support for further assistance.

Service and guarantee commitment

National Instruments (NI) provides a certain level of service and guarantee for the NI PCI – 5911. The standard warranty period and specific terms may vary, but generally, NI stands behind the quality of its products. In case of any defects in materials or workmanship during the warranty period, NI will repair or replace the card as per its warranty policy.

NI also offers technical support to its customers. Their global technical team is available to assist with any issues related to the installation, configuration, or operation of the NI PCI – 5911. Customers can contact NI support via phone, email, or online chat for prompt assistance. Additionally, NI provides a wealth of online resources, such as application notes, user manuals, and software updates, to help customers make the most of the NI PCI – 5911 in their applications.