Description

NI PXIE – 8861 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PXIE-8861 |

| Manufacturer | National Instruments (NI) |

| Product category | Embedded controller |

| Processor | Intel Xeon E3 – 1505L v5 Quad – Core Processor (up to 3.2 GHz) |

| Memory | Up to 32GB DDR4 2133 MHz |

| Storage | 256GB M.2 SSD (expandable) |

| PXI Express interface | x16 Gen 3 PXI Express interface for high – speed data transfer |

| Communication interfaces | Gigabit Ethernet, USB 3.0, Serial ports |

| Operating system | Supports Windows 10 IoT Enterprise, NI Linux Real – Time |

| Dimensions | 10.16 cm (W) x 17.78 cm (D) x 3.81 cm (H) |

| Power consumption | 65 W typical, 100 W maximum |

| Operating temperature | 0 °C to 55 °C |

| Storage temperature | – 40 °C to 70 °C |

NI PXIE-8861

Product introduction

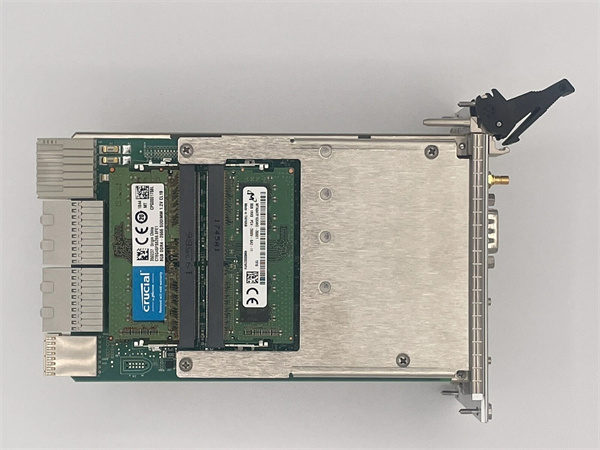

The NI PXIE-8861 is a high – performance embedded controller from National Instruments (NI), engineered to meet the rigorous demands of advanced test, measurement, and automation systems. As a key component of the PXI Express (PXle) platform, it offers exceptional processing power, high – speed data transfer capabilities, and versatile compatibility, making it an ideal choice for a wide spectrum of applications.

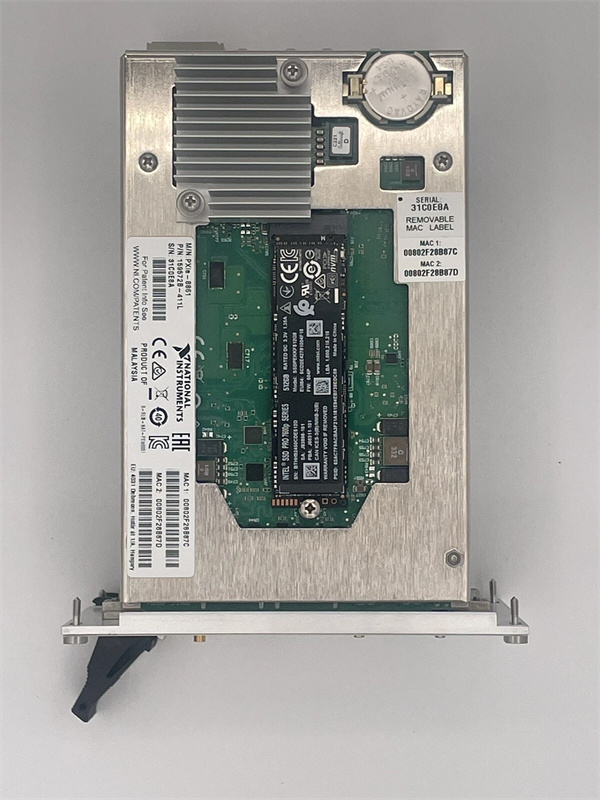

Equipped with an Intel Xeon E3 – 1505L v5 Quad – Core Processor that can reach speeds of up to 3.2 GHz, the NI PXIE-8861 can handle complex computational tasks with ease. Its support for up to 32GB of DDR4 memory and a 256GB expandable M.2 SSD ensures smooth operation even when dealing with large – scale data processing. The x16 Gen 3 PXI Express interface enables ultra – fast data transfer, facilitating seamless communication between the controller and other PXI Express modules. Whether it’s for real – time data acquisition in industrial automation, complex simulation in aerospace research, or high – throughput testing in electronics manufacturing, the PXIE-8861 provides the reliability and performance required to drive these applications forward. Its compatibility with multiple operating systems further enhances its usability, allowing users to choose the environment that best suits their specific requirements.

Core advantages and technical highlights

Powerful Processing Performance: The NI PXIE-8861‘s Intel Xeon E3 – 1505L v5 Quad – Core Processor offers robust computing capabilities. In data – intensive applications, such as high – speed data acquisition and real – time analytics, it can efficiently process large volumes of data, ensuring accurate and timely results. The ability to reach up to 3.2 GHz clock speed, combined with the multi – core architecture, enables parallel processing of tasks, significantly improving overall system performance. For example, in a semiconductor testing setup where multiple tests need to be run simultaneously on different components, the PXIE-8861 can handle the computational load without any lag, providing quick and precise test results.

High – speed Data Transfer: With its x16 Gen 3 PXI Express interface, the PXIE-8861 achieves extremely fast data transfer rates. This is crucial for applications that demand rapid data exchange between the controller and other PXI Express modules, like high – speed data acquisition cards or advanced signal processing units. In a high – definition video testing system, the high – speed data transfer allows for seamless capture and analysis of video streams in real – time, reducing latency and ensuring smooth operation. The fast data transfer also enables efficient communication with external devices via the Gigabit Ethernet and USB 3.0 interfaces, facilitating integration with other systems and components.

Versatile Compatibility and Expandability: The NI PXIE-8861 supports multiple operating systems, including Windows 10 IoT Enterprise and NI Linux Real – Time, giving users the flexibility to choose the software environment that best fits their application. This compatibility extends to a wide range of NI and third – party software and hardware, allowing for easy integration into existing systems. Additionally, its expandable storage feature, with the 256GB M.2 SSD being just the base option, enables users to increase the storage capacity as per their data – storage requirements. Whether it’s storing large amounts of test data or running complex software applications, the expandability of the PXIE-8861 ensures that it can adapt to evolving needs over time.

Reliable and Compact Design: Built with high – quality components, the PXIE-8861 is designed for reliable operation in various environments. Its compact form factor, measuring 10.16 cm (W) x 17.78 cm (D) x 3.81 cm (H), makes it suitable for installation in space – constrained setups. The efficient power management, with a typical consumption of 65 W and a maximum of 100 W, ensures stable operation while minimizing heat generation. The operating temperature range of 0 °C to 55 °C and storage temperature range of – 40 °C to 70 °C make it adaptable to different working conditions, from controlled laboratory environments to industrial plants.

NI PXIE-8861

Typical application scenarios

In industrial automation, the NI PXIE-8861 serves as the central control unit for complex manufacturing processes. In an automotive assembly line, it can coordinate the operation of multiple robotic arms, conveyor belts, and quality – control sensors. By collecting data from various sensors in real – time and processing it with its powerful processor, the PXIE-8861 can adjust the production line parameters to ensure optimal efficiency and product quality. Its high – speed data transfer capabilities allow for seamless communication with other automation devices, enabling smooth integration into the overall factory – floor control system.

In the aerospace industry, the PXIE-8861 is used for aircraft component testing and flight simulation. It can simulate different flight conditions and control the test equipment to evaluate the performance and reliability of aircraft engines, avionics, and other critical components. The controller’s ability to handle complex simulations and process large amounts of test data in real – time is essential for ensuring the safety and performance of aerospace products. Its compatibility with different software environments also allows aerospace engineers to use their preferred simulation and analysis tools, enhancing the overall research and development process.

In electronics manufacturing, the NI PXIE-8861 is employed for high – throughput testing of printed circuit boards (PCBs) and electronic components. It can control the test equipment, acquire test data at high speeds, and perform in – depth analysis to detect any faults or defects. The expandable storage feature of the PXIE-8861 is particularly useful in this context, as it can store vast amounts of test data for further review and quality assurance purposes. Its reliable performance and fast data processing capabilities help in reducing the testing time and improving the overall production yield.

Related model recommendations

- NI PXIE-8880: A more powerful version of the PXIE-8861, featuring a higher – end Intel Xeon processor and increased memory capacity. It is suitable for applications that demand even more intensive computational power, such as large – scale data analytics and complex 3D simulations. When the requirements of a project grow to handle more complex tasks, upgrading to the PXIE-8880can provide the necessary performance boost.

- NI PXIe – 8840: A cost – effective alternative to the PXIE-8861, offering a balance of performance and affordability. It is ideal for less – demanding applications, such as basic data acquisition and simple control systems in educational institutions or small – scale industries. While it may have slightly lower processing power and memory capacity, it still provides reliable operation for a wide range of standard tasks.

- NI cRIO – 9068: A CompactRIO controller with a different architecture, designed for rugged and distributed control applications. It can be used in combination with the PXIE-8861in scenarios where local control at the edge of the network is required, along with centralized data processing and management. For example, in a large – scale industrial monitoring system, the cRIO – 9068 can handle local data acquisition and pre – processing, while the PXIE-8861 can perform in – depth analysis and overall system control.

- NI PXIE-8135: An embedded controller that focuses on providing a balance between processing power and power efficiency. It is suitable for applications where energy consumption is a concern without sacrificing too much on performance. In battery – powered or portable measurement systems, the PXIE-8135can be a good alternative or complementary option to the PXIE-8861.

- NI PXIe – 8845: Similar to the PXIE-8861but with enhanced I/O capabilities, offering more communication interfaces and higher – speed data transfer for specific I/O – intensive applications. In systems that require extensive connectivity to a large number of external devices, such as in a complex sensor network or a multi – device control setup, the PXIe – 8845 can provide the additional I/O resources needed.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXIE-8861, ensure that the PXI Express chassis is powered off and properly grounded. Check the compatibility of the chassis with the PXIE-8861 in terms of slot type and power supply capacity. Use appropriate electrostatic – discharge (ESD) protection measures, such as wearing an ESD wrist strap, to prevent damage to the controller during handling. When inserting the PXIE-8861 into the chassis, carefully align it with the PXI Express slot and gently push it in until it clicks into place, ensuring a secure connection. Connect all necessary cables, including power cables, Ethernet cables, USB cables, and any other communication cables, according to the wiring diagrams provided in the product manual.

Maintenance suggestions: Regularly check the status indicators on the PXIE-8861 and the PXI Express chassis to monitor its operation. Clean the ventilation openings of the PXIE-8861 and the chassis regularly to prevent dust accumulation, which can affect the cooling efficiency and lead to overheating. Periodically update the operating system, device drivers, and firmware of the PXIE-8861 to ensure compatibility with the latest software and hardware, as well as to benefit from performance improvements and security patches. In case of any abnormal behavior, such as system crashes, slow performance, or communication errors, first check the cable connections, power supply, and configuration settings. If the problem persists, refer to the troubleshooting guide in the product manual. When replacing any components, use only genuine NI parts to ensure the reliability and performance of the PXIE-8861.

Service and guarantee commitment

We stand firmly behind the quality of the NI PXIE-8861. The product comes with a comprehensive warranty that covers any manufacturing defects. During the warranty period, if the PXIE-8861 fails to perform as specified, we will repair or replace it free of charge. Our dedicated technical support team is available around – the – clock to assist customers with installation, commissioning, and any technical issues that may arise. We offer a wide range of online resources, including detailed user manuals, software drivers, and application notes, to help users make the most of the PXIE-8861. Additionally, we are committed to continuous product improvement and regularly release firmware updates and software enhancements to ensure that the PXIE-8861 remains at the forefront of embedded controller technology, providing our customers with reliable and high – performing solutions for their measurement and automation needs.