Description

NI PCI – 6115 Product Description

1. General Information

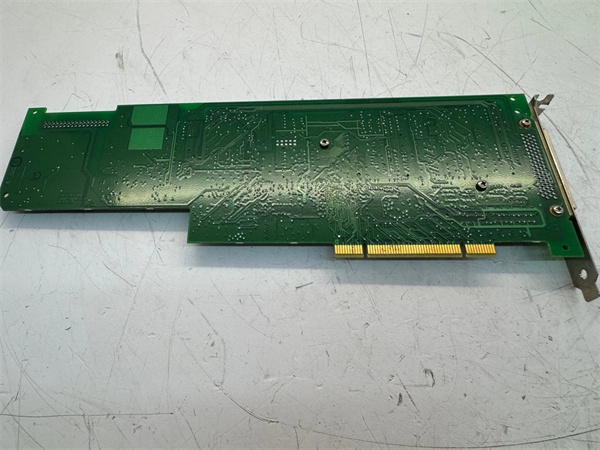

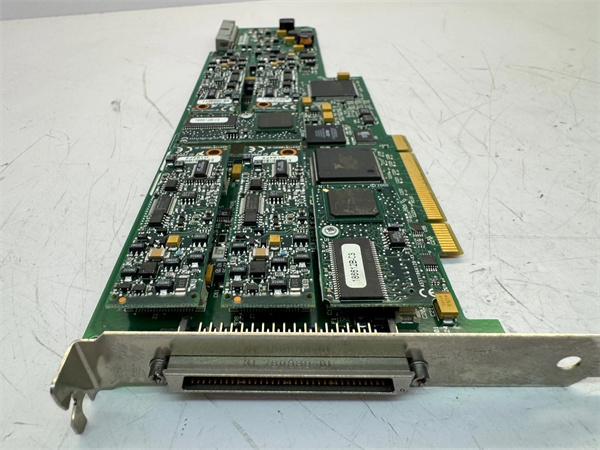

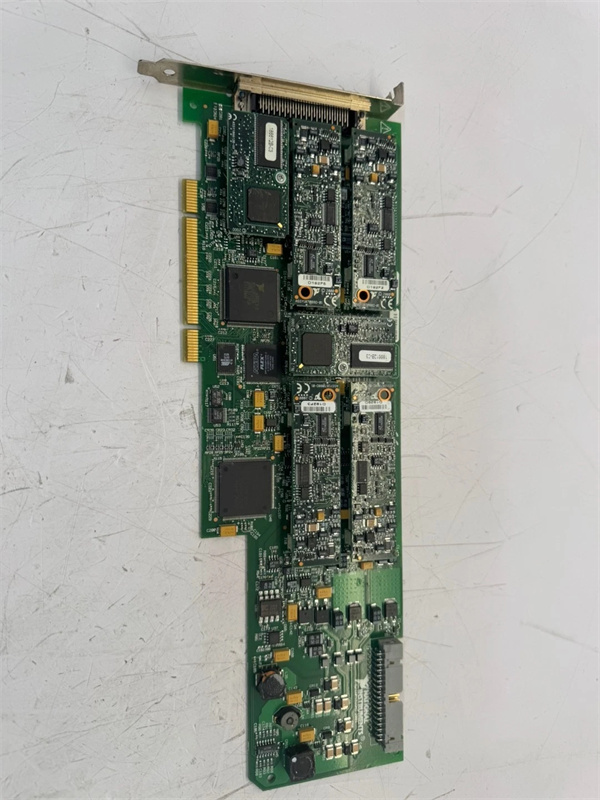

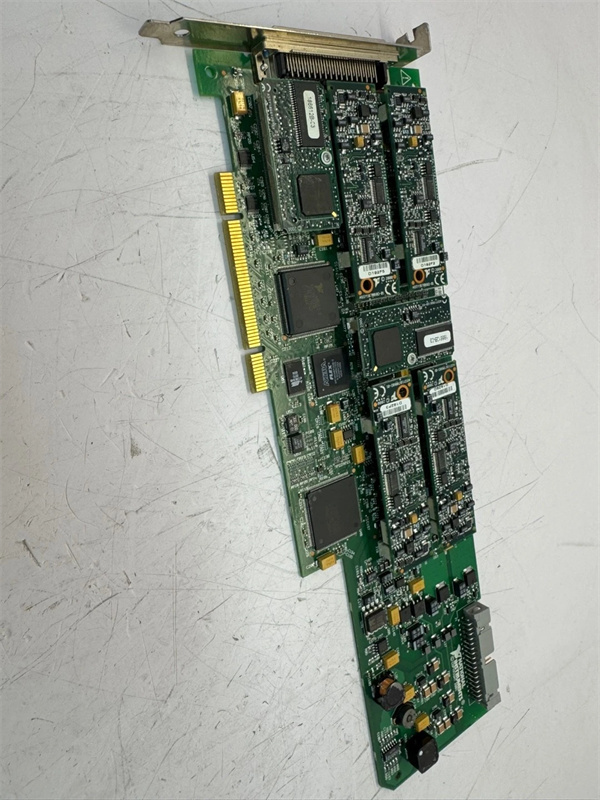

Product Model: NI PCI – 6115

Manufacturer: National Instruments (NI)

Product Category: High – Performance Multifunction Data Acquisition (DAQ) Card (PCI Interface)

2. Detailed Parameter Table

| Parameter Name | Parameter Value |

| Electrical Performance | |

| Analog Input | 4 channels with dedicated ADC per channel; Resolution: 12 – bit; Sampling rate: Up to 10 MS/s per channel; Input range: ±0.2 V, ±0.5 V, ±1 V, ±2 V, ±5 V, ±10 V, ±20 V, ±42 V (8 software – selectable ranges) |

| Analog Output | 2 channels; Resolution: 16 – bit; Output range: 0–5 V, 0–10 V, ±5 V (selectable); Update rate: 4 MS/s (single – channel), 2.5 MS/s (dual – channel) |

| Digital I/O | 8 lines (configurable as input or output); Logic levels: 5 V TTL/CMOS |

| Counter/Timer | 2 × 24 – bit up/down counters (max frequency 80 MHz); PWM output: Supported via counter/timer (up to 2 MHz) |

| Physical Size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 230 g |

| Interface Type | PCI 2.2 compliant (32 – bit, 33 MHz); Dual 68 – pin SCSI – II connectors for analog/digital signals; 10 – pin header for counter/timer signals; RTSI bus connector (8 – line) for multi – device synchronization |

| Communication Protocol | PCI bus for data transfer; Compatible with NI – DAQmx and legacy Traditional NI – DAQ drivers; Supports scatter – gather DMA for efficient high – speed data transfer; Supports register – level programming and SCPI |

| Environmental Requirements | Operating temperature: 0 °C to 50 °C; Storage temperature: – 20 °C to 70 °C; Relative humidity: 10% to 90% (non – condensing); Operating altitude: Up to 2000 m; Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half – sine) |

| Installation Method | Standard PCI slot mounting (compatible with PCI 2.1/2.2 chassis); Easy – to – install design for quick setup in various systems |

| Performance Indicators | Analog input accuracy: ±0.02% full scale (FS) at 25 °C; Analog output accuracy: ±0.1% FS; Digital I/O max sink/source current: 24 mA per line; Counter frequency: Up to 80 MHz; FIFO buffer: Larger compared to some models (for enhanced data buffering during high – speed sampling); Signal – to – Noise Ratio (SNR): > 80 dB (analog input); Channel crosstalk: < – 75 dB (at 100 kHz) |

| Power Requirements | Powered by PCI bus (typical: 10 W); Peak power consumption: 15 W (during 10 MS/s sampling) |

| Compatibility | Works with Windows XP/Vista/7/10 (32 – bit/64 – bit); Compatible with NI LabVIEW (v8.0+), LabWindows/CVI, C/C++, Visual Basic 6.0; Full support for Traditional NI – DAQ; Good compatibility with newer .NET/Python via NI – DAQmx bridge |

NI PCI-6115

3. Product Introduction

The NI PCI – 6115 is a high – performance multifunction DAQ card from National Instruments. It is engineered to meet the needs of applications that demand rapid data acquisition with a fair degree of precision. Compared to some of its counterparts like the PCI – 6110, the PCI – 6115 offers a higher sampling rate at 10 MS/s per channel for analog input, making it more suitable for scenarios where capturing fast – changing signals is crucial.

This card is well – suited for a diverse range of users. In academic research related to high – speed phenomena, such as studying the behavior of fast – acting chemical reactions or high – frequency electrical signals, the PCI – 6115 can accurately sample and record data. In industrial settings, it can be used for real – time monitoring and control in processes like high – speed manufacturing lines or complex power distribution systems.

4. Core Advantages and Technical Highlights

High – Speed Data Acquisition: With a maximum sampling rate of 10 MS/s per channel for analog input, the PCI – 6115 can quickly capture transient and high – frequency signals. In power grid monitoring, it can precisely sample the fast – fluctuating voltage and current waveforms, enabling the detection of power quality issues such as harmonics and voltage sags in a timely manner. This high – speed sampling ensures that no important signal details are missed.

Dedicated ADC per Channel: Each of the 4 analog input channels on the PCI – 6115 has its own dedicated analog – to – digital converter (ADC). This design maximizes the device’s throughput and improves multi – channel accuracy. In a multi – sensor data acquisition system, for example, where different sensors are measuring various physical quantities simultaneously, the dedicated ADCs allow for independent and accurate conversion of each sensor’s signal, reducing interference and crosstalk between channels.

Flexible Input Ranges: The 8 selectable analog input ranges, from ±0.2 V to ±42 V, provide great flexibility. In automotive applications, it can interface with a wide variety of sensors, such as those measuring battery voltage (which can range from a few volts to tens of volts) or sensor signals with small amplitudes. This adaptability makes the PCI – 6115 suitable for different types of electrical measurements in various industries.

Enhanced Memory and FIFO Buffering: Although specific memory capacity details may vary, the PCI – 6115 generally has larger memory and more substantial FIFO buffers compared to some similar models. During continuous high – speed data acquisition, these buffers can store a significant amount of data, reducing the likelihood of data loss. In a high – speed imaging system where large amounts of data need to be buffered before being transferred to the computer’s main memory, the enhanced buffering capabilities of the PCI – 6115 can ensure smooth data flow.

5. Typical Application Scenarios

Automotive Testing: In automotive R&D, the PCI – 6115 can be used to test various vehicle components. For instance, it can measure the high – voltage signals in electric vehicle battery management systems, monitor the performance of engine control units by sampling sensor signals at high rates, or test the response of automotive electronics to high – frequency electromagnetic interference. The card’s ability to handle a wide range of input voltages and high – speed sampling makes it an ideal choice for such applications.

Radar and Sonar Systems: In radar applications, the PCI – 6115 can capture the high – frequency echo signals from radar transmitters. Its high – speed sampling rate enables the accurate detection and analysis of the position, speed, and distance of objects. Similarly, in sonar systems for underwater detection, the card can sample the ultrasonic signals reflected from underwater objects, providing detailed information about the underwater environment.

High – Energy Physics Experiments: In particle accelerator facilities, the PCI – 6115 can be used to record the signals from detectors. These detectors generate high – speed, short – lived signals when particles collide. The card’s 12 – bit resolution and 10 MS/s sampling rate allow for the precise measurement of these signals, which is essential for researchers to study the fundamental properties of particles and the interactions between them.

NI PCI-6115

6. Related Model Recommendations

NI PCI – 6110: As mentioned earlier, the PCI – 6110 has a lower analog input sampling rate (up to 5 MS/s per channel) compared to the PCI – 6115. It also has a different set of features in terms of the number of analog input channels (4 channels in PCI – 6110 compared to 4 in PCI – 6115, but with different ADC arrangements). The PCI – 6110 may be a more cost – effective option for applications where the sampling rate requirements are not as stringent, such as some general – purpose data logging applications in industrial plants.

NI PXI – 6115: The PXI – 6115 is a PXI – based version of the card. It offers similar electrical performance in terms of analog input resolution (12 – bit), sampling rate (up to 10 MS/s per channel), and other features. The main difference lies in the form factor and the PXI – specific features it can utilize when installed in a PXI chassis, such as better synchronization capabilities within a PXI system. It can be a better choice for applications where a more modular and integrated PXI – based setup is preferred, like in large – scale test and measurement systems in a laboratory environment.

NI USB – 6363: This USB – powered DAQ module has a different form factor and power source. It offers 16 – bit analog input resolution (higher than PCI – 6115 in this aspect) but a lower sampling rate (up to 500 kS/s per channel). The advantage of the USB – 6363 is its portability, making it suitable for field applications where a quick and easy – to – connect data acquisition solution is needed. For example, in on – site environmental monitoring, the USB – 6363 can be easily connected to a laptop, while the PCI – 6115 is more suitable for permanent installations in a controlled environment.

7. Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the NI PCI – 6115, power off the target PC and ensure it has an available PCI 2.1/2.2 slot. Wear an ESD wristband to prevent electrostatic discharge that could damage the card. Insert the card firmly into the slot, making sure the PCI edge connector is fully seated, and secure it with the chassis screw. Connect sensors to the dual 68 – pin SCSI – II terminal blocks according to the type of sensors. For example, use appropriate signal conditioning modules for thermocouples or pressure sensors. Connect the 10 – pin header for counter/timer signals if required, and use an 8 – line RTSI cable for multi – device synchronization.

Commissioning: Download the appropriate NI – DAQmx or legacy Traditional NI – DAQ drivers from NI’s official website. Use NI Measurement & Automation Explorer (MAX) to detect the card. Run self – tests provided by MAX to verify the basic functionality of the card, such as analog input and output capabilities, digital I/O status, and counter/timer operations. In LabVIEW or other compatible software, configure the channels and settings according to the application requirements. For example, set the analog input range, sampling rate, and trigger conditions.

Maintenance Suggestions: Regularly check the card for any signs of physical damage, such as bent pins or discolored components. Periodically clean the connectors with isopropyl alcohol to ensure good electrical contact. Calibrate the card at least once a year using NI’s calibration tools. This helps to maintain the accuracy of the analog input and output measurements. In case of any abnormal behavior, such as incorrect readings or communication errors, refer to NI’s online knowledge base or contact their technical support for troubleshooting guidance.

8. Service and Guarantee Commitment

National Instruments provides comprehensive support for the NI PCI – 6115. The standard warranty covers manufacturing defects for a specified period. In addition, NI offers extended service plans that include:

Priority technical support for any issues related to the card, whether it’s hardware – related or software – related. Their team of experts can quickly diagnose and provide solutions to problems such as data acquisition errors or driver compatibility issues.

Periodic software updates to ensure compatibility with the latest operating systems and software development environments. These updates can also enhance the performance and functionality of the card.

Access to NI’s vast knowledge base, which contains application notes, tutorials, and troubleshooting guides. This resource helps users to make the most of the card’s features and solve common problems on their own.

For out – of – warranty repairs, NI has a reliable repair service. Their technicians can replace faulty components and perform thorough testing to ensure the card is restored to its original working condition.