Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PCI-6503 |

| Manufacturer | National Instruments |

| Product Category | Digital I/O PCI Card |

| Form Factor | PCI (compatible with standard PCI slots) |

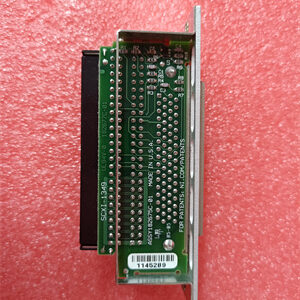

| Digital I/O Channels | 24 bidirectional channels (TTL/CMOS – compatible, 5V operation, 2.4 mA drive capability) |

| Interface Type | 24 – bit Programmable Peripheral Interface (PPI) |

| Handshake Capability | 2 – wire handshake for reliable data transfer |

| Ports | Organized in three 8 – bit ports (A, B, and C); Ports A and B for digital I/O, Port C configurable for data I/O, control, status, or handshake signals |

| Operating Mode | Unidirectional or bidirectional operation modes |

| Power – up State | User – defined power – up state for enhanced flexibility |

| Compatibility | Plug – and – play compatible; works with a variety of operating systems (Windows, Linux, etc.); NI – DAQmx software for easy configuration |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -20 °C to 70 °C |

| Relative Humidity | 10% to 90% non – condensing |

| Compliance Standards | Meets relevant industry standards for electrical safety and electromagnetic compatibility |

| Included Accessories | Driver software (NI – DAQmx); may include connection cables or adapters depending on packaging |

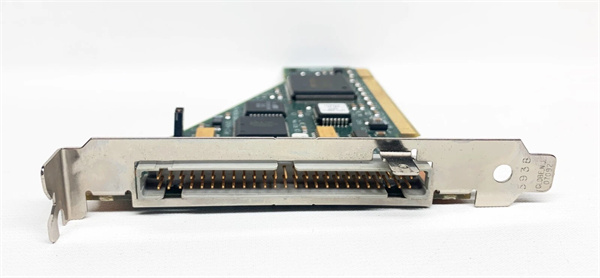

NI PCI-6503

Product introduction

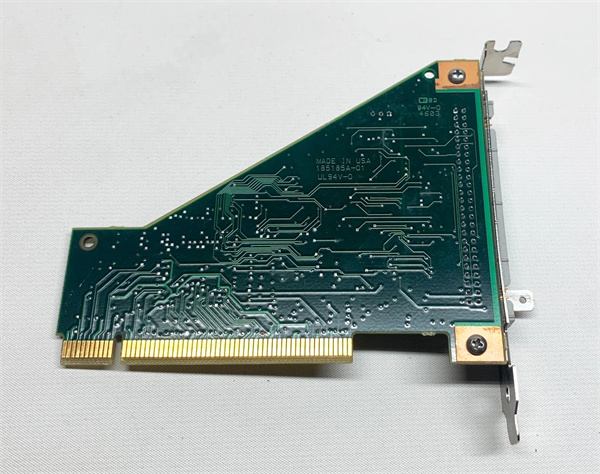

The National Instruments PCI-6503 is a high – performance digital I/O PCI card designed to meet the digital interface needs of a wide range of applications. Leveraging a 24 – bit Programmable Peripheral Interface (PPI), the PCI – 6503 offers 24 channels of digital I/O, making it an ideal choice for scenarios where reliable digital communication with external devices is crucial.

This card is engineered to interface seamlessly with peripherals and other computers. Its ability to operate in either unidirectional or bidirectional modes, along with the 2 – wire handshake capability, ensures accurate and efficient data transfer. The PCI – 6503’s plug – and – play compatibility simplifies the installation process, eliminating the need for a separate card manager for configuration. Additionally, its compatibility with various operating systems allows developers to create cross – platform applications with ease.

Core advantages and technical highlights

Abundant Digital I/O Channels: With 24 bidirectional digital I/O channels, the PCI – 6503 can handle a large number of digital signals simultaneously. In an industrial control system, it can be used to control multiple solenoid valves, sensors, and actuators. For example, in a manufacturing plant’s conveyor system, the PCI – 6503 can use its digital outputs to control the movement of conveyor belts, while its digital inputs monitor the presence of products on the belts, ensuring smooth and coordinated operation.

Flexible Port Configuration: The three 8 – bit ports (A, B, and C) offer great flexibility. Ports A and B are dedicated to digital I/O, while Port C can be configured for different functions such as digital data I/O, control, status, or handshake signals. In a robotic arm control system, Port C can be used to send control signals to the robotic arm’s motor drivers, while Ports A and B handle the digital feedback from the arm’s position sensors.

Reliable Handshake Mechanism: The 2 – wire handshake capability ensures reliable data transfer between the PCI – 6503 and external devices. This is particularly important in applications where data integrity is critical, such as in communication between industrial control systems and programmable logic controllers (PLCs). When the PCI – 6503 sends data to a PLC, the handshake signals confirm that the data has been received correctly, reducing the chances of data errors.

User – Defined Power – up State: The ability to define the power – up state of the card provides enhanced flexibility and safety. In applications where connected devices need to start in a specific state, such as in a power distribution system where relays need to be in an open or closed state at startup, the PCI – 6503 can be configured accordingly. This feature helps prevent unexpected device behavior and ensures smooth startup operations.

Easy Configuration with NI – DAQmx: The PCI – 6503 uses the NI – DAQmx software for configuration. This software simplifies the process of setting up the card’s parameters, such as digital I/O directions, handshake settings, and power – up states. Engineers can use the intuitive interface of NI – DAQmx to quickly configure the PCI – 6503, reducing the time required for system integration and deployment.

Typical application scenarios

Industrial Automation: In industrial settings, the PCI – 6503 is used for controlling and monitoring various processes. It can be integrated into factory automation systems to control machinery, such as in a packaging line where it controls the filling, sealing, and labeling processes. The card’s digital outputs can activate motors, solenoids, and other actuators, while its digital inputs receive feedback from sensors to ensure proper operation.

Test and Measurement in Electronics: In electronics testing, the PCI – 6503 is used to interface with electronic devices for testing purposes. It can be used to apply digital test signals to integrated circuits (ICs) and measure their output responses. For example, in an IC manufacturing facility, the PCI – 6503 can be used to test the functionality of memory chips by sending digital read and write commands and verifying the data returned by the chips.

Laboratory Instrument Control: In research laboratories, the PCI – 6503 can be used to control laboratory instruments. It can interface with devices such as automated sample handlers, spectrometers, and microscopes. For instance, it can control the movement of a robotic sample stage in a fluorescence microscope, allowing for precise positioning of samples for analysis.

NI PCI-6503

Related model recommendations

NI PCI – 6509: This is an industrial 96 – channel digital I/O interface for PCI – bus computer systems. It offers a much higher number of digital I/O channels compared to the PCI – 6503, making it suitable for applications that require a large number of digital connections. In a large – scale industrial control system with numerous sensors and actuators, the PCI – 6509 can be used to manage all the digital I/O operations. Each line can be individually configured for input or output, and it has a higher current drive capability (up to 24 mA per channel), allowing it to directly drive external digital devices such as solid – state relays.

NI USB – 6501: A USB – based digital I/O device that offers a more portable option. It has similar digital I/O functionality to the PCI – 6503 but connects via USB, making it convenient for on – site testing or applications where a PCI slot is not available. For example, in a field service technician’s toolkit, the USB – 6501 can be used to quickly diagnose and test equipment in the field without the need to open the computer case to install a PCI card.

NI LabVIEW Professional Development System: This software suite is ideal for programming and controlling the PCI – 6503. LabVIEW’s graphical programming environment makes it easy to develop applications for digital I/O control, data acquisition, and system monitoring. Engineers can use LabVIEW to create custom interfaces for the PCI – 6503, allowing for real – time control and monitoring of industrial processes or laboratory experiments.

Installation, commissioning and maintenance instructions

Installation Preparation: Before installing the PCI – 6503, ensure that the host computer has an available standard PCI slot. Power off the computer and use a screwdriver to open the computer case. Ground yourself using an anti – static wristband to prevent electrostatic discharge (ESD) damage to the card. Install the NI – DAQmx software from the provided CD or download it from the NI website. Align the PCI – 6503 with the PCI slot and firmly press it into place until it is fully seated. Secure the card to the computer case with the provided screw. Close the computer case and power on the computer. The operating system should detect the new hardware if the drivers are installed correctly.

Commissioning: After installation, open the NI – DAQmx configuration utility. This utility allows you to configure the settings for the PCI – 6503, such as digital I/O directions, handshake settings, and user – defined power – up states. Test the card by connecting a known digital device (e.g., a digital logic probe or a simple LED circuit) to the appropriate channels and use the NI – DAQmx software to send and receive digital signals. Verify that the signals are correctly transmitted and received. If there are any issues, double – check the connections, settings, and ensure that the drivers are up to date.

Maintenance Suggestions: Regularly inspect the PCI – 6503 for any signs of physical damage, such as bent pins on the connectors. Clean the card and its connectors periodically using compressed air to remove dust and debris, which can affect the electrical connections. To ensure reliable operation, periodically check the software settings to make sure they have not been accidentally changed. If the card experiences issues such as incorrect digital signal readings or communication problems, first check the software settings, update the drivers, and then verify the physical connections. In case of persistent problems, contact NI’s technical support for further assistance.

Service and guarantee commitment

National Instruments provides a standard warranty for the PCI – 6503, covering defects in materials and workmanship. The warranty period gives users peace of mind, knowing that if the card fails due to manufacturing issues, it will be repaired or replaced. NI also offers a global technical support team that is available to assist users with any questions or problems related to the PCI – 6503. Whether it’s software configuration, hardware compatibility, or troubleshooting, the support team can be reached via email, phone, or online forums.

In addition, NI provides a wealth of online resources for the PCI – 6503, including user manuals, application notes, and software development kits. These resources help users get the most out of the device, from initial installation to developing complex applications. For customers with critical applications, NI may offer extended support contracts, which can include priority technical assistance, software updates, and additional calibration services, ensuring the long – term reliability and performance of the PCI – 6503.