Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product model | NI PCI-7811 |

| Manufacturer | National Instruments (NI) |

| Product category | PCI-Based Reconfigurable I/O (RIO) Data Acquisition Card (CompactRIO Compatible) |

| FPGA chip | Xilinx Spartan-3E (1M gates, configurable for custom logic) |

| Analog input channels | 8 single-ended / 4 differential channels |

| Analog input resolution | 12-bit |

| Maximum sampling rate (analog input) | 200 kS/s per channel (simultaneous sampling) |

| Analog input voltage range | ±10 V (fixed) |

| Analog output channels | 2 channels (12-bit resolution) |

| Maximum output rate (analog output) | 100 kS/s per channel |

| Digital I/O lines | 40 lines (TTL/CMOS-compatible, bidirectional; configurable via FPGA) |

| Counter/timer | 4 x 32-bit counters (implementable via FPGA for frequency/pulse measurement) |

| Communication interface | PCI (32-bit, 33 MHz); compatible with 3.3 V and 5 V PCI slots |

| Operating temperature range | 0 °C to 55 °C (32 °F to 131 °F) |

| Storage temperature range | -20 °C to 70 °C (-4 °F to 158 °F) |

| Power consumption | +5 VDC @ 2.0 A (max); +12 VDC @ 0.6 A (max); -12 VDC @ 0.2 A (max) |

| Memory | 16 MB DDR2 SDRAM (for FPGA data buffering); 2 MB Flash memory (for FPGA configuration) |

| Calibration support | On-board self-calibration (software-triggered); annual external calibration recommended |

| Software compatibility | NI-RIO driver, LabVIEW FPGA Module, LabVIEW, C/C++ (via NI-RIO API) |

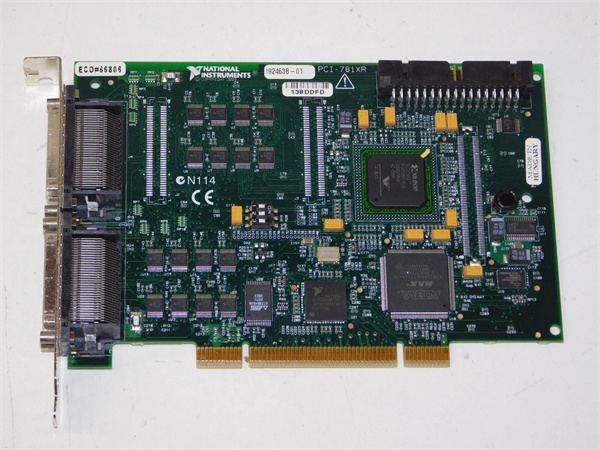

NI PCI-7811

Product Introduction

The NI PCI-7811 is a reconfigurable I/O (RIO) DAQ card from National Instruments (NI), designed to bridge the gap between fixed-function DAQ cards (like the NI PCI-6221) and fully customizable industrial controllers. As part of NI’s CompactRIO ecosystem, the NI PCI-7811 integrates a Xilinx FPGA with analog/digital I/O, enabling users to program custom real-time logic—from low-latency control loops to specialized signal processing—without hardware redesigns.

Unlike the NI PCI-6221 (focused on high-precision measurement), the NI PCI-7811 prioritizes flexibility: its 1M-gate FPGA can be reconfigured to handle unique tasks like custom triggering, parallel data processing, or protocol emulation (e.g., CAN, SPI). When paired with NI’s LabVIEW FPGA Module, the NI PCI-7811 lets engineers build tailored systems—such as a real-time motor controller or a custom sensor data logger—by graphically programming the FPGA. This adaptability makes the NI PCI-7811 a top choice for industries like automotive testing, academic research, and industrial automation, where off-the-shelf solutions cannot meet specific requirements.

Core Advantages and Technical Highlights

FPGA-Based Customization for Unique Workflows: The NI PCI-7811’s Xilinx Spartan-3E FPGA is its defining advantage, allowing users to implement custom logic that fixed-function cards like the NI PCI-6221 cannot match. For example, in automotive ECU testing, engineers program the FPGA on the NI PCI-7811 to emulate a CAN bus interface—enabling the card to send/receive CAN messages while simultaneously sampling sensor data (analog input) and controlling test fixtures (digital output). This integration replaces three separate devices (DAQ card, CAN interface, controller) with one NI PCI-7811, reducing system complexity and latency.

Low-Latency Real-Time Control: With FPGA logic executed in hardware (not software), the NI PCI-7811 achieves sub-microsecond latency for control tasks—critical for applications like robotics or precision manufacturing. A factory automation team, for instance, uses the NI PCI-7811 to control a robotic arm: the FPGA runs a 1 kHz position control loop, reading encoder data (digital I/O) and adjusting motor voltage (analog output) with <500 ns latency. This speed ensures the arm moves with pinpoint accuracy, outperforming software-based controllers that introduce millisecond delays.

40 Digital I/O Lines for Scalable Control: The NI PCI-7811 includes 40 configurable digital I/O lines—nearly double the NI PCI-6221’s 24 lines—making it ideal for large-scale digital systems. In a semiconductor test setup, technicians use these lines to control 16 relays (output) and read 24 test points (input) on a chip, all synchronized via the FPGA. The lines can also be grouped to implement parallel communication protocols (e.g., 8-bit parallel data transfer), further expanding the NI PCI-7811’s utility for custom test benches.

Simultaneous Sampling for Phase-Coherent Data: Unlike the NI PCI-6221 (which uses a multiplexed analog input), the NI PCI-7811 supports simultaneous sampling across its 8 analog inputs. This ensures phase-coherent data—essential for applications like structural vibration analysis, where engineers connect 4 accelerometers (differential mode) to the NI PCI-7811 to measure vibration across a machine frame. Simultaneous sampling eliminates timing skew between channels, enabling accurate phase difference calculations and reliable fault detection.

Typical Application Scenarios

The NI PCI-7811 excels in custom real-time applications across industries. In automotive powertrain testing, it is used to validate engine control units (ECUs): engineers program the NI PCI-7811’s FPGA to simulate crankshaft position signals (digital output) and sample fuel injector voltage (analog input) at 200 kS/s. The FPGA processes this data in real time to calculate injector timing accuracy, while digital I/O lines trigger a test chamber’s temperature control. This setup lets the team validate ECU performance under dynamic conditions—something fixed-function DAQ cards like the NI PCI-6221 cannot do without external controllers.

In academic robotics research, the NI PCI-7811 is a staple for building custom robot controllers: students program the FPGA to run a 500 Hz closed-loop control for a 4-degree-of-freedom robotic arm. The NI PCI-7811 reads encoder feedback (digital I/O) and sends motor command signals (analog output), with the FPGA ensuring sub-millisecond response times to avoid instability. Its compatibility with LabVIEW FPGA also lets students prototype logic quickly—e.g., adding collision detection by programming the FPGA to monitor current draw (analog input) and stop the arm if thresholds are exceeded.

In industrial machine vision, the NI PCI-7811 synchronizes cameras and lighting: the FPGA triggers 4 cameras (digital output) and samples 2 light sensors (analog input) to adjust brightness in real time. This synchronization ensures consistent image capture, even as part geometry changes on a production line. The NI PCI-7811’s FPGA also processes camera trigger timestamps to calculate part position, eliminating the need for a separate vision controller and reducing system costs.

NI PCI-7811

Related Model Recommendations

NI PCI-6221: A fixed-function high-precision DAQ card, a complementary model to the NI PCI-7811 for setups needing 16-bit measurement (e.g., medical sensor testing) alongside FPGA-based control.

NI PCIe-7821R: A PCI Express (PCIe) version of the NI PCI-7811, featuring a more powerful Xilinx Kintex-7 FPGA and faster data transfer—ideal for users transitioning to PCIe systems needing higher FPGA performance.

NI PCI-7813R: An upgraded RIO card with 16 analog inputs (double the NI PCI-7811) and a 2M-gate FPGA, suitable for multi-sensor applications (e.g., 8-channel vibration monitoring).

NI cRIO-9074: A CompactRIO chassis with integrated FPGA, a portable alternative to the NI PCI-7811 for field testing (e.g., on-site turbine control) where PCI-based systems are impractical.

NI PCI-7851R: A high-speed RIO card with 12-bit analog inputs sampling at 1 MS/s, a faster alternative to the NI PCI-7811 for dynamic signal applications (e.g., high-speed motor testing).

NI PCI-6071: A legacy E Series DAQ card, a cost-effective backup for the NI PCI-7811 in non-critical applications where FPGA customization is unnecessary.

NI PXIe-7846R: A PXIe-based RIO module with a Xilinx Zynq SoC, a modular upgrade to the NI PCI-7811 for large-scale test systems requiring PXI synchronization (e.g., automotive ECU production testing).

NI PCI-7831R: A RIO card with 8 analog outputs (4x the NI PCI-7811), ideal for applications needing multiple control signals (e.g., 4-axis robotic arm control).

Installation, Commissioning and Maintenance Instructions

Installation preparation: Before installing the NI PCI-7811, confirm the host PC has an available 32-bit PCI slot (3.3 V or 5 V compatible) and meets system requirements (Windows 7/10, 8 GB RAM, 1 GB free disk space for NI-RIO drivers and LabVIEW FPGA). Power off the PC and disconnect all power sources. Use an anti-static wristband and mat to handle the NI PCI-7811—its FPGA and DDR2 memory are sensitive to electrostatic discharge. Align the card’s edge connector with the PCI slot, press firmly until the bracket seats against the case, and secure with two screws (to prevent vibration-induced FPGA connection issues). After installation, install the latest NI-RIO driver and LabVIEW FPGA Module, then run the “NI RIO Hardware Setup” utility to configure the FPGA and verify I/O functionality.

Maintenance suggestions: Clean the NI PCI-7811’s PCI connector every 2 months with low-pressure compressed air to remove dust, which can cause FPGA communication errors. Back up the FPGA configuration to Flash memory (via NI-RIO utility) after programming—this ensures the NI PCI-7811 retains custom logic if power is lost. If the NI PCI-7811 exhibits FPGA configuration failures, reflash the FPGA using the backup file or reinstall the NI-RIO driver. Run self-calibration quarterly to maintain analog input accuracy, especially for applications requiring traceable measurements. For hardware issues (e.g., unresponsive digital I/O), contact NI support—do not open the card, as this voids the warranty and risks damaging the FPGA.

Service and Guarantee Commitment

The NI PCI-7811 comes with a standard 1-year manufacturer’s warranty, covering defects in materials and workmanship. NI guarantees the NI PCI-7811 will meet all published technical specifications during the warranty period, with free repair or replacement of defective units. Customers can extend coverage to 5 years via NI’s Extended Service Program (ESP), which includes annual calibration, priority technical support for FPGA programming, and expedited repair (48-hour turnaround for industrial customers).

NI provides specialized support for the NI PCI-7811 through its RIO and FPGA expert team: users gain access to application notes (e.g., “Programming Custom CAN Logic on the NI PCI-7811’s FPGA”), video tutorials on LabVIEW FPGA, and direct phone/email support for logic design challenges. For custom projects (e.g., building a real-time ECU test system), NI offers professional services—including FPGA code development, system integration, and on-site training—to help users maximize the NI PCI-7811’s flexibility. This commitment ensures users have the expertise to leverage the card’s custom capabilities, protecting their investment in reconfigurable automation technology.