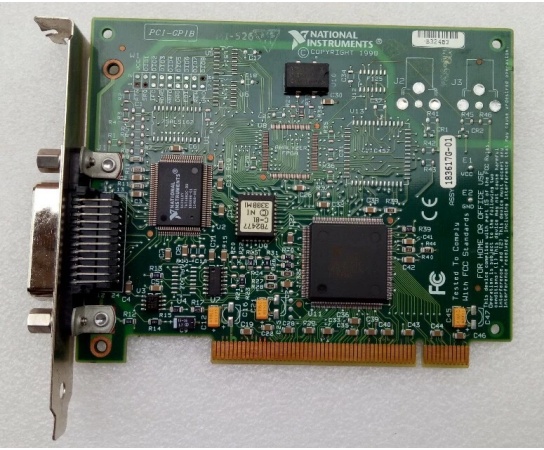

Description

NI PCI-GPIB

- •

Model Number: PCI-GPIB - •

Manufacturer: National Instruments - •

Product Type: PCI IEEE 488 Interface Controller - •

Bus Standard: IEEE 488.2 compliant - •

Maximum Transfer Rate: 1.5 MB/s - •

Number of Controllable Devices: Up to 14 devices plus the controller - •

Data Transfer Modes: DMA, interrupt, and programmed I/O - •

GPIB Connector: Standard IEEE 488 24-pin connector - •

Bus Interface: 32-bit PCI - •

GPIB Cable Length: Supports maximum 2 meters per device, 20 meters total - •

Signals: 8 data lines, 8 control lines - •

Talker/Listener Functions: Controller, Talker, Listener capabilities - •

Handshake Modes: 3-wire interlocked handshake - •

Operating Temperature: 0°C to 55°C - •

Power Consumption: 5W typical (from PCI bus) - •

Compatibility: Windows and Linux operating systems NI PCI-GPIB