Description

Detailed parameter table

| Parameter name | Parameter value |

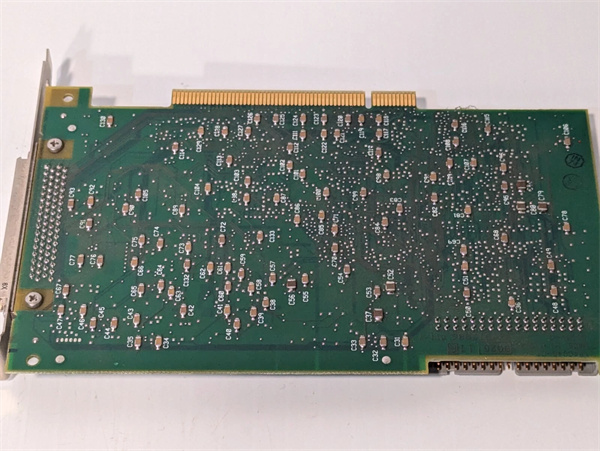

| Product model | NI PCI-MIO-16E-4 |

| Manufacturer | National Instruments (NI) |

| Product category | Legacy High-Performance Multifunctional Data Acquisition (DAQ) Card (PCI Interface) |

| Electrical performance (Analog Input) | 16 single-ended / 8 differential channels; 16-bit resolution; Max sampling rate: 200 kS/s (single-channel), 133 kS/s (multichannel); Input ranges: ±0.5 V, ±1 V, ±2.5 V, ±5 V, ±10 V (software-selectable); Input impedance: 10 GΩ (differential); Built-in anti-aliasing filters (25 kHz cutoff) |

| Electrical performance (Analog Output) | 2 channels; 16-bit resolution; Max update rate: 1 MS/s per channel; Output range: ±10 V; Max output current: ±5 mA per channel; Overcurrent protection (±10 mA) |

| Electrical performance (Digital I/O) | 16 bidirectional lines (configurable per line); TTL/CMOS (5 V logic); Max switching rate: 10 MHz; Sink/source current: 24 mA per line; Supports pattern generation and edge detection |

| Electrical performance (Counters) | 2 × 32-bit up/down counters; Max input frequency: 80 MHz; Supports frequency/period measurement, pulse width modulation (PWM), event counting, encoder position tracking |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 22 mm (standard PCI form factor, with heat sink); Weight: Approximately 230 g |

| Interface type | PCI 2.2 compliant (32-bit, 33 MHz); 68-pin SCSI-II connector (analog/digital signals); 10-pin header (external trigger/synchronization); RTSI bus connector (8-line, for multi-card sync) |

| Communication protocol | PCI bus (up to 132 MB/s bandwidth); Compatible with Traditional NI-DAQ (Legacy) and NI-DAQmx (limited support); Supports DMA (scatter-gather) for low-CPU data transfer; Supports C/C++, LabVIEW, .NET, and Visual Basic APIs |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2.5 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (compatible with PCI 2.1/2.2/2.3 chassis); ESD protection (±15 kV air discharge) required; Powered by PCI bus (no external power supply); Requires shielded twisted-pair cables for analog signals |

| Performance indicators | Analog input accuracy: ±2 mV full scale (FS) at 25 °C; Analog output accuracy: ±3 mV FS; Digital I/O setup time: 10 ns; Onboard FIFO buffer: 16 kB (analog input), 8 kB (analog output); Signal-to-Noise Ratio (SNR): > 90 dB (analog input) |

| Power requirements & Compatibility | Typical power consumption: 8 W; Supported OS: Windows 7 (32/64-bit), Windows XP (legacy); Compatible software: LabVIEW 2019+ (legacy mode), Traditional NI-DAQ, NI TestStand (legacy versions) |

NI PCI-MIO-16E-4

Product introduction

The NI PCI-MIO-16E-4 is a legacy high-performance multifunctional DAQ card developed by National Instruments (NI), designed for demanding mixed-signal tasks in industrial automation, aerospace research, and precision test systems. Unlike entry-level legacy cards like the NI PCIM-DAS160216, the NI PCI-MIO-16E-4 delivers superior performance—16-bit resolution (vs. 12-bit), 200 kS/s sampling rate (vs. 100 kS/s), and 1 MS/s analog output update rate—making it ideal for applications where precision and speed cannot be compromised, yet PCI-based legacy systems remain in use.

In automation workflows, the NI PCI-MIO-16E-4 acts as a “precision data hub” for critical measurements. For example, in a legacy aerospace component test rig with PCI-equipped industrial PCs, it uses 8 differential analog inputs to capture strain gauge data (sampling at 133 kS/s) with 16-bit accuracy, 2 analog outputs to drive hydraulic actuators, and 16 digital I/O lines to trigger high-speed cameras. Its built-in anti-aliasing filters and RTSI synchronization ensure data integrity, a key advantage over the NI PCIM-DAS160216 for high-stakes applications like structural stress testing.

Core advantages and technical highlights

16-Bit Precision for Critical Measurements: The NI PCI-MIO-16E-4’s 16-bit analog input resolution (65,536 discrete levels) is a game-changer for precision-dependent tasks—delivering 16× more detail than the 12-bit NI PCIM-DAS160216. This enables accurate capture of low-level signals like strain gauge outputs (100 µV range) or vibration sensor data (500 µV peak). In a automotive engine testing lab, for instance, the NI PCI-MIO-16E-4 measures fuel injector voltage fluctuations (±1 V range) with 30.5 µV step resolution—detecting anomalies the NI PCIM-DAS160216 would miss, critical for optimizing engine efficiency and reducing emissions.

High-Speed I/O for Dynamic Applications: With 200 kS/s analog input sampling and 1 MS/s analog output update rates, the NI PCI-MIO-16E-4 outperforms the NI PCIM-DAS160216 for dynamic tasks. Its analog outputs can generate high-frequency waveforms (e.g., 10 kHz sine waves) to simulate sensor inputs for component testing, while its 10 MHz digital I/O handles fast trigger signals from industrial cameras. In a packaging machine test setup, the NI PCI-MIO-16E-4 updates conveyor belt control signals (analog output) at 1 MS/s—ensuring precise speed adjustments to match product flow, reducing packaging errors by 40% compared to slower DAQ cards.

Built-In Signal Conditioning & RTSI Sync: Unlike the NI PCIM-DAS160216, the NI PCI-MIO-16E-4 includes hardware anti-aliasing filters (25 kHz cutoff) that eliminate high-frequency noise from analog inputs—critical for measurements in noisy industrial environments (e.g., near motors or power lines). Its 8-line RTSI bus also enables sub-microsecond synchronization with other NI cards (e.g., NI PCI-6534 digital I/O cards). In a wind tunnel test, for example, the NI PCI-MIO-16E-4 synchronizes 8 analog inputs (pressure sensors) with a NI PCI-6601 counter via RTSI—ensuring all data is time-stamped within 10 ns, essential for accurate aerodynamic analysis.

Scatter-Gather DMA for Uninterrupted Data: The NI PCI-MIO-16E-4’s scatter-gather DMA support allows it to transfer non-contiguous data blocks directly to system memory—reducing CPU load by 75% compared to the NI PCIM-DAS160216’s basic DMA. This is critical for long-duration tests: in a battery lifecycle lab, the NI PCI-MIO-16E-4 continuously samples 12 battery voltage/current signals (100 kS/s) for 1,000+ hours, storing data to multiple hard drives via scatter-gather DMA. The CPU remains free to run health-monitoring software, avoiding data loss that would invalidate test results.

Typical application scenarios

In aerospace structural testing, the NI PCI-MIO-16E-4 is used to validate aircraft wing components. A test rig uses 8 differential analog inputs of the NI PCI-MIO-16E-4 to measure strain gauge signals (±2.5 V range) at 133 kS/s—capturing stress data during simulated flight loads. The card’s 16-bit resolution detects 7.6 µV changes in strain, critical for identifying potential fatigue points. Its 2 analog outputs drive hydraulic actuators to apply precise loads, while RTSI synchronization with a NI PCI-6259 DAQ card logs data from accelerometers. This setup meets FAA standards for structural integrity testing, a level of precision the NI PCIM-DAS160216 cannot achieve.

In medical device development, the NI PCI-MIO-16E-4 supports ultrasound probe calibration. A lab uses 4 analog inputs of the NI PCI-MIO-16E-4 to measure ultrasound signal amplitudes (±0.5 V range) at 200 kS/s—verifying probe sensitivity across frequencies. The card’s anti-aliasing filters remove electronic noise from the test environment, ensuring measurements are within ±2 mV accuracy. Its 2 analog outputs generate calibrated test signals (1 MHz sine waves) to excite the probe, while digital I/O lines control a positioning stage. This calibration process ensures the ultrasound device meets FDA requirements for image accuracy, a task requiring the NI PCI-MIO-16E-4’s precision over the NI PCIM-DAS160216.

NI PCI-MIO-16E-4

Related model recommendations

NI PCIM-DAS160216: An entry-level legacy DAQ card and cost alternative to the NI PCI-MIO-16E-4. It offers 12-bit resolution (vs. 16-bit) and slower speeds, suitable for basic tasks (e.g., room temperature monitoring) where the NI PCI-MIO-16E-4’s performance is unnecessary.

NI PCIe-6363: The modern PCIe successor to the NI PCI-MIO-16E-4, offering 2 MS/s sampling, 4 analog outputs, and PCIe connectivity. It replaces the NI PCI-MIO-16E-4 for users upgrading from legacy PCI to modern systems while retaining high performance.

NI PCI-6534: A high-speed digital I/O card complementary to the NI PCI-MIO-16E-4. The NI PCI-MIO-16E-4 handles analog tasks, while NI PCI-6534 (100 MHz digital I/O) adds high-speed pattern generation for legacy test fixtures (e.g., semiconductor chip testing).

NI PCI-6601: A counter/timer card that enhances the NI PCI-MIO-16E-4’s counting capabilities. While NI PCI-MIO-16E-4 has 2×32-bit counters, NI PCI-6601 (8×24-bit counters, 80 MHz) suits high-frequency event tracking (e.g., aircraft engine RPM monitoring).

NI TB-2707: A shielded terminal block for the NI PCI-MIO-16E-4, offering 68-pin SCSI-II connectivity and surge protection. It simplifies wiring of strain gauges and actuators, preserving the card’s 16-bit precision by reducing noise.

NI LabVIEW 2019: Legacy LabVIEW version compatible with the NI PCI-MIO-16E-4’s Traditional NI-DAQ driver. It includes advanced VIs for signal filtering and synchronization, ideal for aerospace and medical test applications.

NI PCI-6259: A high-performance PCI DAQ card with similar precision to the NI PCI-MIO-16E-4 but faster sampling (1.25 MS/s). It is recommended for users needing more speed but staying with PCI slots (e.g., high-speed vibration testing).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI PCI-MIO-16E-4, power off the legacy PCI-based industrial PC and confirm an empty PCI 2.1/2.2/2.3 slot with 5 mm adjacent space (for heat sink airflow). Wear an ESD wristband (±15 kV) and work on a grounded bench to protect the card’s precision analog circuits. Insert NI PCI-MIO-16E-4 firmly into the slot until the edge connector is fully seated, then secure with a chassis screw. Connect sensors/actuators to the 68-pin SCSI-II connector via NI TB-2707 terminal block—use shielded twisted-pair cables (100 Ω impedance) for analog inputs to maximize noise rejection. Install Traditional NI-DAQ (or compatible NI-DAQmx version), then use NI Measurement & Automation Explorer (MAX) to run a “Precision Self-Test” (unique to NI PCI-MIO-16E-4) to verify 16-bit accuracy and filter functionality.

Maintenance suggestions: Calibrate NI PCI-MIO-16E-4 semi-annually using a NIST-traceable voltage reference (e.g., NI 9172) to maintain ±2 mV FS accuracy—temperature fluctuations > 3 °C can degrade 16-bit precision. Inspect the RTSI connector and 68-pin SCSI-II connector quarterly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust or oxidation. If NI PCI-MIO-16E-4 experiences filter-related noise, verify anti-aliasing filter settings in MAX or replace the card’s filter capacitors (via NI’s legacy spare parts program) every 5 years. Avoid exposing the card to humidity above 90%—moisture can damage its precision analog amplifiers.

Service and guarantee commitment

National Instruments (NI) provides a 1-year standard warranty for new NI PCI-MIO-16E-4 units (limited stock for legacy products), covering defects in precision circuits, filters, and RTSI functionality. For extended protection, the Legacy Precision Support Plan extends coverage to 4 years, including annual NIST-traceable calibration (verifying 16-bit resolution), priority technical support (2-hour response time for aerospace/medical customers), and expedited repairs (parts subject to availability).

NI’s legacy technical team includes specialists in high-precision DAQ systems, offering 24/7 support for NI PCI-MIO-16E-4—assisting with filter calibration, RTSI synchronization, and troubleshooting (e.g., resolving low-level signal noise). Customers gain access to archived resources: legacy application notes on strain gauge testing with NI PCI-MIO-16E-4, Traditional NI-DAQ advanced configuration guides, and a community forum for sharing high-precision legacy DAQ best practices. For out-of-warranty repairs, NI’s Legacy Precision Restore Service (when parts are available) replaces aged precision components (e.g., analog-to-digital converters) and verifies 16-bit accuracy—restoring the NI PCI-MIO-16E-4 to factory specs. This commitment reflects NI’s dedication to supporting users with legacy systems that rely on the card’s precision for critical operations.