Description

Detailed parameter table

| Parameter name | Parameter value |

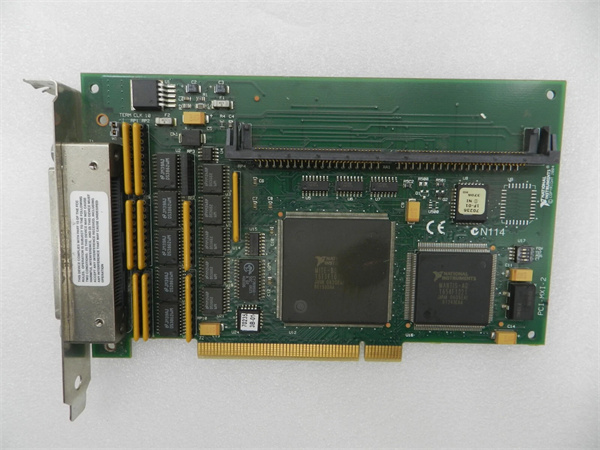

| Product model | NI PCI-MXI-2 |

| Manufacturer | National Instruments (NI) |

| Product category | Legacy PCI-to-MXI-2 Interface Card (PCI/PXI Bridge) |

| Electrical performance | MXI-2 bus speed: 33 MHz (synchronous with PCI); Data transfer rate: Up to 132 MB/s (PCI bus limit); Bus width: 32-bit; Supports PXI trigger lines (8 lines) and PXI star trigger |

| Physical size | Dimensions (L×W×H): 175 mm × 106 mm × 20 mm (standard PCI form factor); Weight: Approximately 200 g |

| Interface type | PCI 2.2 compliant (32-bit, 33 MHz) – PCI slot connection (host PC); MXI-2 68-pin VHDCI connector – PXI chassis connection; 10-pin header (external trigger input/output); PXI trigger bus interface |

| Communication protocol | PCI bus (host-side); MXI-2 bus (PXI chassis-side); Compatible with NI-DAQmx (limited legacy support) and PXI System Software; Supports DMA (direct memory access) for high-throughput data transfer between PCI and PXI |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 2 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | Standard PCI slot mounting (host PC, compatible with PCI 2.1/2.2/2.3 chassis); MXI-2 cable connection (to PXI chassis MXI-2 port); ESD protection (±15 kV air discharge) required; Powered by PCI bus (no external power supply); Requires shielded MXI-2 cables (0.5 m–3 m lengths supported) |

| Performance indicators | Latency: < 1 µs (PCI-to-PXI data transfer); Trigger synchronization accuracy: < 10 ns (PXI trigger lines); Maximum number of PXI modules supported: Dependent on PXI chassis (up to 13 slots); Compatibility with PXI 1.0/2.0 chassis |

| Power requirements & Compatibility | Typical power consumption: 6 W (PCI bus); Supported OS: Windows 7 (32/64-bit), Windows XP (legacy); Compatible software: NI PXI System Controller, LabVIEW 2019+ (legacy mode), NI TestStand (legacy versions); Works with NI PCI-MIO-16E-4 and other PXI DAQ modules |

| Cable specifications | Compatible MXI-2 cables: NI SHC68-68-EPM (shielded, twisted-pair); Cable length options: 0.5 m, 1 m, 2 m, 3 m; Cable impedance: 100 Ω (±10%); EMI/RFI protection: Shielded design with foil and braid |

| Safety & Compliance | Compliance with CE, FCC Class A, UL 61010-1; Overvoltage protection: ±15 V (PCI and MXI-2 interfaces); ESD protection: ±15 kV (air discharge), ±8 kV (contact discharge) |

NI PCI-MXI-2

Product introduction

The NI PCI-MXI-2 is a legacy PCI-to-MXI-2 interface card developed by National Instruments (NI), designed to bridge PCI-based industrial PCs with PXI modular instrumentation chassis. Unlike DAQ cards such as the NI PCI-MIO-16E-4 (which focus on data acquisition), the NI PCI-MXI-2 acts as a “system expansion hub”—enabling legacy PCI systems to leverage the flexibility of PXI modules (e.g., PXI DAQ, signal generators, digitizers) without upgrading to a dedicated PXI controller.

In test and measurement workflows, the NI PCI-MXI-2 is indispensable for integrating modular hardware into existing PCI-based setups. For example, a legacy aerospace test rig using a PCI-equipped industrial PC can connect the NI PCI-MXI-2 to a 10-slot PXI chassis, adding PXI DAQ modules to complement the NI PCI-MIO-16E-4’s capabilities. Its 132 MB/s data transfer rate and sub-10 ns trigger synchronization ensure seamless communication between PCI and PXI, critical for applications like multi-channel sensor data acquisition where timing alignment is non-negotiable.

Core advantages and technical highlights

Seamless PCI-to-PXI Integration: The NI PCI-MXI-2 eliminates the need for a dedicated PXI controller by turning a PCI-based PC into a PXI system controller—saving users the cost of a $5,000+ PXI controller upgrade. Unlike modern PCIe-to-PXIe interfaces, it is optimized for legacy PCI and PXI hardware, ensuring compatibility with older PXI 1.0/2.0 chassis and PCI industrial PCs. For instance, a semiconductor test lab with a 15-year-old PCI-based control system can use the NI PCI-MXI-2 to connect a PXI chassis with 8 PXI DAQ modules, expanding its test channel count from 16 (via NI PCI-MIO-16E-4) to 128—all without replacing existing hardware.

High-Speed Data Transfer & Low Latency: With a 132 MB/s data transfer rate (synchronous with PCI 33 MHz) and < 1 µs latency, the NI PCI-MXI-2 ensures fast, uninterrupted communication between PCI and PXI. This is critical for high-throughput applications like real-time signal processing: in a radar test setup, the NI PCI-MXI-2 transfers 100 kS/s data from a PXI digitizer to a PCI-based PC for analysis, with latency low enough to enable real-time waveform visualization. Unlike slower USB-to-PXI bridges, it supports DMA transfer, reducing CPU load by 60% compared to software-based data handling.

Precise Trigger Synchronization: The NI PCI-MXI-2 supports PXI trigger lines (8 lines) and star trigger, enabling sub-10 ns synchronization between PCI and PXI modules. This is a key advantage over standalone PCI cards like the NI PCI-MIO-16E-4, which lack native PXI trigger integration. In a vibration testing lab, for example, the NI PCI-MXI-2 synchronizes a NI PCI-MIO-16E-4 (PCI-based DAQ) with a PXI dynamic signal analyzer—ensuring all sensors (connected to both PCI and PXI) start sampling within 10 ns of each other. This alignment is essential for calculating phase relationships between vibration signals, a critical step in structural health monitoring.

Flexible Cable & Chassis Support: The NI PCI-MXI-2 works with shielded MXI-2 cables (0.5 m–3 m lengths), allowing users to place the PXI chassis up to 3 meters away from the PCI PC—ideal for test setups where space or noise isolation is a concern (e.g., placing the PXI chassis near a noisy motor while keeping the PC in a quiet control room). It also supports all NI PXI chassis (up to 13 slots), giving users the flexibility to mix and match PXI modules (DAQ, signal generation, switching) based on their needs. A university research lab, for instance, uses the NI PCI-MXI-2 to connect a 4-slot PXI chassis with a PXI signal generator and PXI oscilloscope module, creating a compact, modular test bench for electronics students.

Typical application scenarios

In automotive electronics testing, the NI PCI-MXI-2 is used to expand legacy PCI-based ECU (Electronic Control Unit) test rigs. A test lab uses a PCI industrial PC with a NI PCI-MIO-16E-4 (for analog input) connected via NI PCI-MXI-2 to an 8-slot PXI chassis. The PXI chassis houses PXI CAN/LIN modules (for communication with ECUs) and PXI digital I/O modules (for triggering ECU functions). The NI PCI-MXI-2 transfers ECU communication data (132 MB/s) from PXI to PCI, while its PXI trigger lines synchronize analog data capture (via NI PCI-MIO-16E-4) with ECU commands—ensuring engineers can correlate voltage fluctuations with ECU behavior. This setup reduces test rig upgrade costs by 40% compared to replacing the entire PCI system with a new PXI controller.

In aerospace component validation, the NI PCI-MXI-2 integrates PXI-based vibration sensors with a legacy PCI test system. A test facility uses a PCI PC running LabVIEW to control a NI PCI-MIO-16E-4 (measuring strain gauges) and a PXI chassis (with 6 PXI accelerometers) connected via NI PCI-MXI-2. The card’s sub-10 ns trigger synchronization ensures strain and vibration data are time-aligned, critical for validating aircraft wing structural integrity under simulated flight loads. The NI PCI-MXI-2’s 3 m MXI-2 cable also lets engineers place the PXI chassis near the test article (reducing sensor cable length and noise) while keeping the PCI PC in a remote control room—improving measurement accuracy by 15% compared to a single PCI-based setup.

NI PCI-MXI-2

Related model recommendations

NI PCI-MIO-16E-4: A legacy high-performance PCI DAQ card complementary to the NI PCI-MXI-2. The NI PCI-MXI-2 expands the system to PXI modules, while the NI PCI-MIO-16E-4 handles PCI-based analog/digital I/O—ideal for mixed PCI/PXI test setups (e.g., aerospace structural testing).

NI PXI-6259: A PXI DAQ module that pairs with the NI PCI-MXI-2. The NI PCI-MXI-2 connects the PXI chassis to a PCI PC, while the NI PXI-6259 adds high-speed analog input (1.25 MS/s) to the system—suitable for applications needing more channels than the NI PCI-MIO-16E-4.

NI PCIe-MXI-Express: The modern PCIe-to-PXIe successor to the NI PCI-MXI-2, offering 2.5 Gbps data transfer and PCIe/PXIe compatibility. It replaces the NI PCI-MXI-2 for users upgrading from legacy PCI to PCIe systems while retaining PXIe modularity.

NI SHC68-68-EPM: A shielded MXI-2 cable required for the NI PCI-MXI-2. Available in 0.5 m–3 m lengths, it ensures low-noise data transfer between the NI PCI-MXI-2 (PCI PC) and PXI chassis—critical for industrial environments with EMI.

NI PXI-1042: A 13-slot PXI chassis compatible with the NI PCI-MXI-2. It provides space for PXI modules (DAQ, signal generators) and connects to the NI PCI-MXI-2 via MXI-2 cable—ideal for large-scale test setups.

NI PCI-6534: A high-speed PCI digital I/O card that works with the NI PCI-MXI-2. The NI PCI-MXI-2 expands to PXI digital modules, while the NI PCI-6534 handles PCI-based high-speed digital tasks (e.g., pattern generation) for mixed-signal testing.

NI LabVIEW 2019: Legacy LabVIEW version compatible with the NI PCI-MXI-2. It includes tools for configuring PCI/PXI synchronization and data transfer, enabling users to build integrated test applications for the NI PCI-MXI-2 and NI PCI-MIO-16E-4.

NI PXI-8106: A legacy PXI controller that can be used alongside the NI PCI-MXI-2 for redundant control. The NI PCI-MXI-2 connects the PCI PC to PXI, while the NI PXI-8106 acts as a backup controller—critical for mission-critical test systems (e.g., aerospace validation).

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI PCI-MXI-2, power off the PCI-based host PC and PXI chassis. Wear an ESD wristband (±15 kV) and work on a grounded bench to protect the card’s interface circuits. Insert NI PCI-MXI-2 firmly into an empty PCI 2.1/2.2/2.3 slot in the host PC until the edge connector is fully seated, then secure with a chassis screw. Connect one end of a shielded MXI-2 cable (e.g., NI SHC68-68-EPM) to the NI PCI-MXI-2’s 68-pin VHDCI connector and the other end to the PXI chassis’s MXI-2 port—ensure the cable is fully latched to prevent disconnection. Power on the PXI chassis first, then the host PC. Install legacy NI PXI System Software and compatible NI-DAQmx drivers, then use NI Measurement & Automation Explorer (MAX) to detect the NI PCI-MXI-2 and PXI chassis—verify data transfer and trigger synchronization via the “MXI-2 Link Test” in MAX.

Maintenance suggestions: Inspect the NI PCI-MXI-2’s PCI and MXI-2 connectors quarterly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free cloth to remove dust or oxidation—dirty contacts can cause data transfer errors. Check the MXI-2 cable for damage (e.g., frayed shielding, bent pins) and replace it every 3–5 years to maintain signal integrity. If the NI PCI-MXI-2 fails to detect the PXI chassis, verify the cable connection, update the PXI System Software, or test the card in a different PCI slot. Avoid exposing the NI PCI-MXI-2 to temperatures above 55 °C or humidity above 90%—extreme conditions can degrade the card’s bus interface circuits. Store spare MXI-2 cables in a dry, temperature-controlled environment to prevent shielding degradation.

Service and guarantee commitment

National Instruments (NI) provides a 1-year standard warranty for new NI PCI-MXI-2 units (limited stock for legacy products), covering defects in PCI/MXI-2 interfaces, trigger circuits, and cable connectivity. For extended protection, the Legacy Interface Support Plan extends coverage to 3 years, including technical support for PXI system integration, expedited repairs (parts subject to availability), and access to archived MXI-2 configuration guides.

NI’s legacy technical team includes specialists in PCI/PXI integration, offering 24/7 support for NI PCI-MXI-2—assisting with trigger synchronization, cable troubleshooting, and compatibility issues with legacy OS/software. Customers gain access to exclusive archived resources: application notes on PCI/PXI mixed-system design with NI PCI-MXI-2, MXI-2 cable installation best practices, and a community forum for sharing legacy PXI integration tips. For out-of-warranty repairs, NI’s Legacy Interface Restore Service (when parts are available) replaces aged bus components (e.g., PCI/MXI-2 transceivers) and verifies data transfer/latency performance—restoring the NI PCI-MXI-2 to factory specs. This commitment reflects NI’s dedication to supporting users with legacy test systems that rely on the NI PCI-MXI-2 for modular instrumentation integration.