Description

NI PXI-1031 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXI-1031 |

| Manufacturer | National Instruments |

| Product Category | PXI Chassis |

| Form Factor | 3U PXI (19-inch rack-mountable) |

| Slot Count | 5 slots (1 system slot, 4 peripheral slots) |

| Backplane Bandwidth | 132 MB/s per slot (PXI bus) |

| System Slot | Compatible with PXI controllers (e.g., PXI-8106, PXI-8840) |

| Peripheral Slots | 4 PXI peripheral slots (3U), compatible with PXI and PXI Express modules (via hybrid slots) |

| Power Supply | 100-240 VAC, 50-60 Hz input; 3.3 V, 5 V, ±12 V outputs |

| Maximum Power Output | 120 W total |

| Cooling | Forced-air cooling with variable-speed fans |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -40 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 42.5 cm (width) x 17.7 cm (height) x 37.6 cm (depth) |

| Weight | 7.3 kg |

| Compliance Standards | CE, UL, CSA, FCC Part 15 Class A |

| Rack Mounting | 19-inch rack mountable with included hardware |

NI PXI-1031

Product Introduction

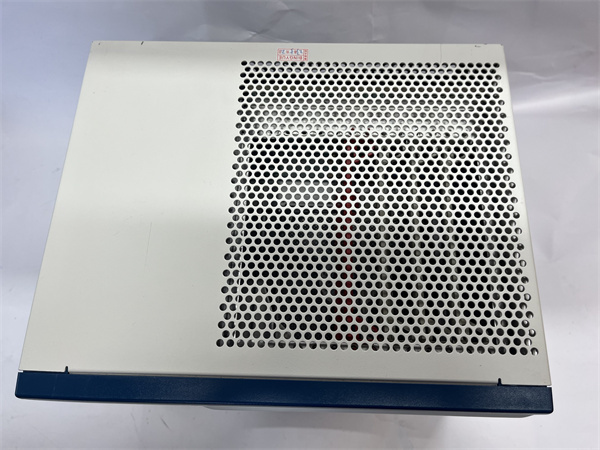

The NI PXI-1031 is a compact 5-slot PXI chassis designed to serve as the backbone of modular test and measurement systems. As a key component of National Instruments’ PXI ecosystem, it provides a standardized platform for integrating PXI controllers, data acquisition modules, signal generators, and other peripheral devices into a single, synchronized system.

Ideal for small to medium-scale applications, the PXI-1031 balances portability and performance. Its 5-slot configuration includes 1 system slot for a PXI controller and 4 peripheral slots for modules, making it suitable for applications ranging from automated testing to embedded control. The chassis leverages the PXI bus architecture to enable high-speed communication between modules, ensuring low-latency data transfer and precise synchronization—critical for time-sensitive measurements. With a rugged design and efficient cooling system, the PXI-1031 operates reliably in both lab and industrial environments, supporting temperatures from 0 °C to 55 °C.

Core Advantages and Technical Highlights

Compact, Space-Efficient Design

The PXI-1031’s 5-slot form factor is optimized for applications where bench space or rack space is limited. Measuring just 17.7 cm in height, it fits easily into 19-inch racks or benchtop setups, making it ideal for portable test systems or small-scale production lines. Despite its compact size, it retains full compatibility with 3U PXI modules, ensuring flexibility in system configuration.

High-Speed Backplane Communication

The chassis features a PXI backplane with 132 MB/s bandwidth per slot, enabling fast data transfer between connected modules and the controller. This high-speed bus is essential for applications such as real-time data acquisition, where large volumes of data must be processed without latency. For example, in a vibration testing setup, the PXI-1031 can synchronize a PXI-6363 DAQ module with a signal analyzer, ensuring time-aligned measurements.

Robust Cooling and Power Management

Equipped with variable-speed fans, the PXI-1031 maintains optimal operating temperatures for modules even under high loads. The cooling system adjusts fan speed based on internal temperature, reducing noise in lab environments while ensuring reliable performance in industrial settings. The 120 W power supply delivers stable 3.3 V, 5 V, and ±12 V outputs, supporting a wide range of PXI modules without the need for external power sources.

Easy Integration and Scalability

The PXI-1031 is plug-and-play compatible with NI’s PXI controllers and modules, simplifying system setup. Users can quickly configure the chassis using NI Measurement & Automation Explorer (MAX), which auto-detects connected devices and facilitates module synchronization. For larger systems, multiple PXI-1031 chassis can be linked via MXI-Express cables, extending the number of available slots while maintaining synchronization.

Typical Application Scenarios

Automated Component Testing

In electronics manufacturing, the PXI-1031 serves as the core of automated test stations for components like sensors or circuit boards. A typical setup might include a PXI controller (e.g., PXI-8106), a digital multimeter module (e.g., PXI-4071), and a switch module (e.g., PXI-2503). The chassis synchronizes these modules to perform sequential tests—measuring voltage, resistance, and signal integrity—with results logged in real time to a database.

Embedded Control Systems

For embedded system development, the PXI-1031 integrates a real-time controller (e.g., PXI-8135) with I/O modules to simulate and test hardware. For example, in automotive engineering, it can mimic engine control unit (ECU) inputs, using analog output modules to generate sensor signals and digital I/O modules to monitor ECU responses. The chassis’s low latency ensures accurate replication of real-world operating conditions.

Portable Data Acquisition

The PXI-1031’s compact size and rugged design make it suitable for field measurements, such as environmental monitoring or structural health testing. Paired with a battery pack and a DAQ module (e.g., PXI-6341), it can collect temperature, pressure, and vibration data in remote locations. The PXI bus ensures that data from multiple sensors is time-stamped and synchronized, enabling accurate analysis of correlated events.

NI PXI-1031

Related Model Recommendations

PXI-8106: A PXI controller with an Intel Core i7 processor, ideal for powering the PXI-1031. It provides the processing power needed for real-time data analysis and control applications.

PXI-6363: A 16-channel DAQ module with 2 MS/s sampling rate, compatible with the PXI-1031. It adds high-speed analog input capabilities for applications like vibration testing.

PXI-2503: A 32-channel relay switch module that integrates with the PXI-1031 to route signals between devices, useful in automated test systems where multiple DUTs (devices under test) are cycled through.

MXI-Express x1: A high-speed interface cable that connects multiple PXI-1031 chassis, enabling system expansion beyond 5 slots while maintaining synchronization.

BNC-2090: A terminal block accessory that simplifies wiring between the PXI-1031’s modules and external sensors/actuators, reducing setup time in lab environments.

Installation, Commissioning, and Maintenance

Installation Steps

Chassis Placement: Mount the PXI-1031 in a 19-inch rack using the included hardware, or place it on a stable benchtop. Ensure adequate ventilation (minimum 10 cm clearance on all sides) to prevent overheating.

Power Connection: Connect the chassis to a 100-240 VAC power source using the provided power cord. Verify that the voltage selector switch (if present) matches the local supply.

Module Installation: Power off the chassis. Insert the PXI controller into the system slot (slot 1) and peripheral modules into slots 2-5, ensuring each module is fully seated and secured with the front-panel screws.

Cabling: Connect external devices (e.g., sensors, DUTs) to the modules using appropriate cables (e.g., BNC, DB-25). For synchronization with external systems, use the chassis’s trigger and clock ports.

Commissioning

Power On: Turn on the PXI-1031. The front-panel power LED should illuminate, and fans should activate momentarily.

Device Detection: Launch NI MAX on the controller. The chassis and connected modules should appear under “Devices and Interfaces.” If not, power cycle the chassis and recheck module seating.

Synchronization Setup: Use MAX to configure triggers and clock signals between modules. For example, route a 10 MHz reference clock from the controller to peripheral modules to ensure time alignment.

Functionality Test: Run a test application (e.g., using LabVIEW) to verify data transfer between modules. For DAQ modules, acquire a test signal and confirm accuracy; for switch modules, verify signal routing.

Maintenance Tips

Fan Inspection: Monthly, check that fans are operating smoothly. Clean dust from fan grilles using compressed air to prevent overheating.

Power Supply Check: Periodically verify that the power supply outputs (3.3 V, 5 V, ±12 V) are within tolerance using a multimeter.

Module Contacts: Every 6 months, remove and reinsert modules to clean electrical contacts, preventing intermittent connections.

Environmental Monitoring: Ensure the chassis operates within the specified temperature and humidity ranges. Avoid exposure to liquids or corrosive gases.

Service and Guarantee Commitment

The NI PXI-1031 is backed by a 2-year standard warranty covering defects in materials and workmanship. NI’s global technical support team provides 24/7 assistance for installation, troubleshooting, and system configuration via phone, email, and online resources.

For calibration and repair, NI offers factory service with ISO 17025-accredited procedures to ensure the chassis meets original performance specifications. Extended warranty options are available for applications requiring long-term support. With a mean time between failures (MTBF) exceeding 100,000 hours, the PXI-1031 is engineered for reliability, supported by NI’s commitment to lifecycle management for legacy PXI products.