Description

NI PXI-2510 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

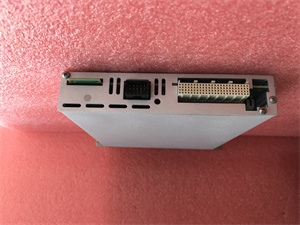

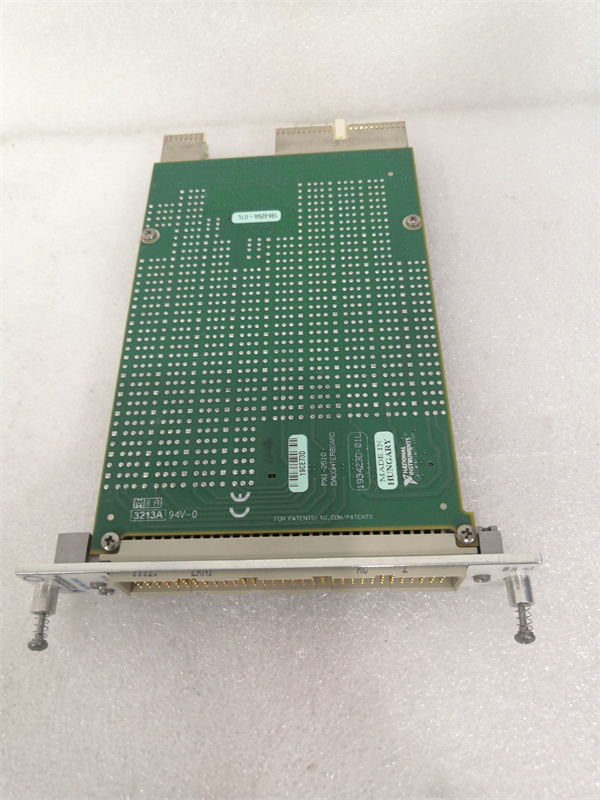

| Product Model | PXI-2510 |

| Manufacturer | National Instruments |

| Product Category | PXI Relay Switch Module |

| Form Factor | 3U PXI |

| Slot Requirement | 1 PXI slot |

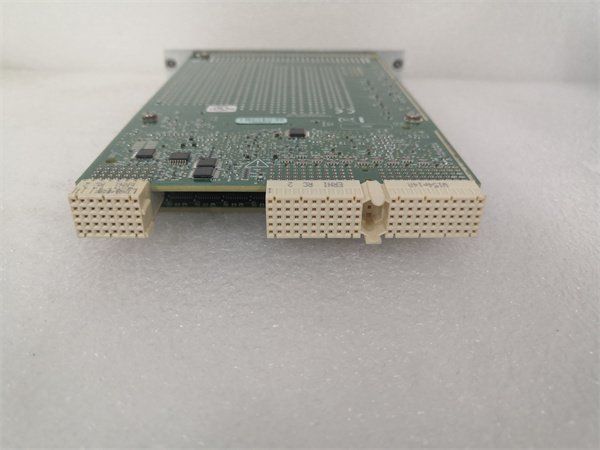

| Switch Configuration | 4×32 matrix (4 rows, 32 columns) |

| Relay Type | Armature relays |

| Maximum Switching Voltage | 250 VDC/250 VAC |

| Maximum Switching Current | 1 A (resistive), 0.5 A (inductive) |

| Maximum Switching Power | 250 VA |

| Contact Resistance | <50 mΩ (typical) |

| Dielectric Withstand Voltage | 1000 VDC (channel-to-channel, channel-to-ground) |

| Insulation Resistance | >10¹⁰ Ω (at 500 VDC) |

| Relay Operate Time | <10 ms |

| Relay Release Time | <5 ms |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -40 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 100 mm (width) x 160 mm (depth) x 37 mm (height) |

| Weight | 300 g |

| Compliance Standards | CE, UL, CSA, FCC Part 15 Class A |

| Software Compatibility | NI Switch Executive, LabVIEW, LabWindows/CVI, .NET, C/C++ |

NI PXI-2510

Product Introduction

The NI PXI-2510 is a high-performance 3U PXI relay switch module designed to facilitate flexible signal routing in automated test and measurement systems. As a key component of National Instruments’ switching solutions, it offers a 4×32 matrix configuration, enabling complex signal connections between multiple sources and destinations.

This module is engineered to handle a wide range of signals, from low-level analog to high-power signals, making it versatile for applications such as component testing, data acquisition system routing, and communication system validation. The PXI-2510 integrates seamlessly with PXI chassis like the PXI-1031, leveraging the PXI bus for synchronized control and low-latency communication. With its robust relay design and reliable performance, it ensures accurate and repeatable signal routing in both lab and industrial environments.

Core Advantages and Technical Highlights

Flexible Matrix Configuration

The 4×32 matrix design of the PXI-2510 provides extensive routing flexibility, allowing up to 4 signal sources to be connected to any combination of 32 destinations. This is particularly useful in multi-channel test systems where signals from multiple instruments (such as signal generators or power supplies) need to be routed to various devices under test (DUTs). For example, in a semiconductor testing setup, the module can route test signals from a waveform generator to different pins of an integrated circuit, streamlining the testing process.

High Power Handling Capability

With a maximum switching voltage of 250 VDC/250 VAC and a current rating of 1 A (resistive), the PXI-2510 can handle both low-level and high-power signals. This versatility eliminates the need for multiple switch modules, reducing system complexity and cost. It can safely switch power signals to components like motors or actuators, as well as sensitive analog signals from sensors, ensuring consistent performance across different signal types.

Fast and Reliable Relay Operation

The armature relays in the PXI-2510 offer fast operate (<10 ms) and release (<5 ms) times, enabling quick signal reconfiguration. This speed is critical in automated test systems where test sequences need to be executed rapidly to maximize throughput. Additionally, the relays have a long mechanical life (up to 10 million operations), ensuring reliable performance over extended periods of use, which is essential for high-volume production testing.

Seamless Integration and Software Support

The PXI-2510 is fully compatible with NI’s software ecosystem, including NI Switch Executive, which simplifies switch system configuration, routing, and management. It also supports popular programming environments like LabVIEW, LabWindows/CVI, .NET, and C/C++, allowing engineers to easily integrate the module into custom test applications. The module can be synchronized with other PXI modules using trigger signals, ensuring precise timing in coordinated test sequences.

Typical Application Scenarios

Electronic Component Testing

In electronics manufacturing, the PXI-2510 is used in automated test stations to route test signals to various components such as resistors, capacitors, and transistors. For example, in a passive component testing setup, the module can connect a digital multimeter to different components on a circuit board, enabling sequential measurement of resistance, capacitance, and inductance. The matrix configuration allows for quick switching between components, reducing test time and increasing production efficiency.

Communication System Validation

In communication systems testing, the PXI-2510 facilitates the routing of signals between transceivers, amplifiers, and antennas. It can simulate different signal paths to test the performance of the system under various conditions. For instance, in a wireless communication test setup, the module can route a modulated signal from a signal generator to different antennas, allowing engineers to evaluate signal strength and quality across different transmission paths.

Data Acquisition System Routing

In data acquisition systems, the PXI-2510 is used to route signals from multiple sensors to a data acquisition (DAQ) module. For example, in an environmental monitoring system, sensors measuring temperature, humidity, and pressure can be connected to the module, which then routes these signals to a DAQ module for processing. The matrix configuration allows for dynamic reconfiguration of sensor connections, enabling engineers to focus on specific sensors or switch between different sensor groups as needed.

NI PXI-2510

Related Model Recommendations

NI PXI-1031: A 5-slot PXI chassis that provides a compact and reliable platform for housing the PXI-2510 and other PXI modules. It offers high-speed backplane communication and efficient cooling, making it ideal for small to medium-scale test systems.

NI PXI-4071: A 6½-digit digital multimeter (DMM) module that can be paired with the PXI-2510 to create a comprehensive component testing system. The PXI-2510 routes signals from the DUT to the PXI-4071, enabling accurate measurement of voltage, current, and resistance.

NI PXI-5421: A function generator module that works with the PXI-2510 to generate and route test signals to DUTs. This combination is useful in applications such as waveform testing and signal integrity analysis.

NI Switch Executive: Software that simplifies the configuration and management of the PXI-2510 and other switch modules. It provides a graphical interface for creating and editing signal routes, as well as tools for monitoring and troubleshooting switch system performance.

NI PXI-6363: A DAQ module that can be integrated with the PXI-2510 to acquire and process signals from multiple sensors. The module’s high-speed sampling capabilities, combined with the PXI-2510’s routing flexibility, make it suitable for dynamic data acquisition applications.

Installation, Commissioning, and Maintenance

Installation Steps

Module Insertion: Power off the PXI chassis (e.g., PXI-1031). Insert the PXI-2510 into an available peripheral slot, ensuring it is fully seated in the backplane. Secure the module using the front-panel screws to prevent movement during operation.

Wiring Connection: Connect the signal sources and destinations to the module’s front-panel connectors using appropriate cables. Refer to the module’s pinout diagram to ensure correct wiring, taking care to match the signal types (analog, digital, power) to the corresponding channels.

Software Installation: Install the latest version of NI Switch Executive and the necessary device drivers from the National Instruments website. Follow the installation wizard to configure the software for the PXI-2510.

Commissioning

Device Detection: Power on the PXI chassis and launch NI Measurement & Automation Explorer (MAX). The PXI-2510 should be detected under the PXI chassis in the device list. If not, check the module’s seating and ensure the drivers are correctly installed.

Configuration in Switch Executive: Open NI Switch Executive and create a new switch system configuration. Add the PXI-2510 to the configuration and define the signal routes based on the test requirements. Use the software’s built-in tools to verify the routes and ensure there are no conflicts.

Functionality Test: Develop a simple test program using LabVIEW or another supported programming language to test the module’s switching functionality. For example, route a test signal from a signal generator to an oscilloscope through the PXI-2510 and verify that the signal is correctly transmitted. Check multiple routes to ensure all relays are operating properly.

Maintenance Tips

Relay Lifespan Monitoring: Track the number of relay operations using NI Switch Executive to anticipate when relays may need replacement. Replace relays once they approach their maximum rated life (10 million operations) to prevent unexpected failures.

Connector Inspection: Periodically inspect the front-panel connectors for signs of damage, corrosion, or loose connections. Clean the connectors with a soft, dry cloth if necessary to ensure good electrical contact.

Environmental Control: Ensure the module operates within the specified temperature (0 °C to 55 °C) and humidity (5% to 95% non-condensing) ranges. Avoid exposing the module to extreme temperatures, moisture, or corrosive environments, as this can degrade performance and shorten relay life.

Software Updates: Keep the NI Switch Executive software and device drivers up to date to benefit from bug fixes, performance improvements, and new features. Check the National Instruments website regularly for updates.

Service and Guarantee Commitment

The NI PXI-2510 is backed by a 2-year standard warranty covering defects in materials and workmanship. National Instruments’ global technical support team provides 24/7 assistance for installation, troubleshooting, and software configuration via phone, email, and online resources.

For calibration and repair services, NI offers factory-calibrated replacements and repair options to ensure the module maintains its specified performance. Extended warranty plans are available for customers requiring long-term support. With a focus on reliability and durability, the PXI-2510 is designed to meet the demands of high-performance test systems, supported by NI’s commitment to quality and customer satisfaction.