Description

Detailed parameter table

| Parameter name | Parameter value |

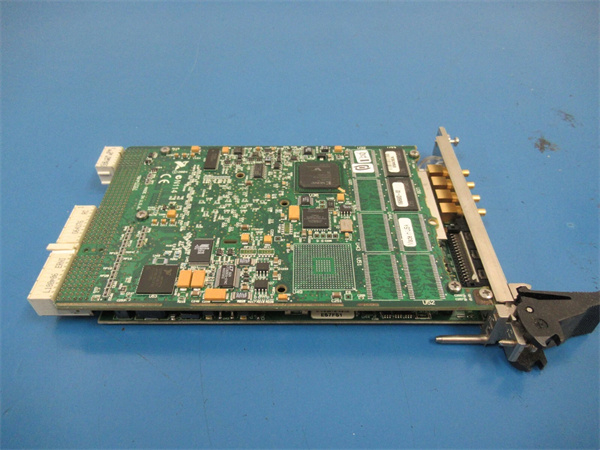

| Product model | NI PXI-5412 |

| Manufacturer | National Instruments (NI) |

| Product category | High-Performance PXI Arbitrary Waveform Generator (AWG) |

| Electrical performance (Waveform Generation) | Single analog output channel; Resolution: 16-bit; Max sampling rate: 100 MS/s; Waveform memory: 16 MB (standard), expandable to 64 MB; Output amplitude range: ±5 V (into 50 Ω), ±10 V (into 1 MΩ); DC offset range: ±5 V (adjustable in 1 mV steps) |

| Signal Quality | Signal-to-Noise Ratio (SNR): > 65 dB (at 1 kHz, 5 Vpp into 50 Ω); Total Harmonic Distortion (THD): < -70 dB (at 1 kHz); Spurious-Free Dynamic Range (SFDR): > 75 dB (at 1 MHz); Rise/fall time: < 3.5 ns (10%–90%, into 50 Ω) |

| Waveform Capabilities | Arbitrary waveform lengths: 1 sample to 16 MB (standard); Predefined waveforms: Sine, square, triangle, ramp, noise (white/pink); Modulation types: AM, FM, PM, FSK, PSK, PWM; Frequency range: DC to 40 MHz (sine wave), DC to 25 MHz (arbitrary waveforms) |

| Physical size | Dimensions (L×W×H): 160 mm × 100 mm × 22 mm (3U PXI form factor); Weight: Approximately 280 g |

| Interface type | PXI 2.0 compliant (32-bit, 33 MHz); PXI trigger bus (8 lines) for synchronization; PXI star trigger support; 50 Ω BNC output connector (analog signal); JTAG port (for firmware updates) |

| Communication protocol | PXI bus for data transfer; Compatible with NI-FGEN driver; Supports DMA (direct memory access) for waveform upload; Supports SCPI, LabVIEW, C/C++, .NET, and Python APIs; Integrates with NI TestStand and LabWindows/CVI |

| Environmental requirements | Operating temperature: 0 °C to 55 °C; Storage temperature: -20 °C to 70 °C; Relative humidity: 10% to 90% (non-condensing); Vibration resistance: 5 g (10 Hz to 500 Hz); Shock resistance: 50 g (11 ms half-sine) |

| Installation method | 3U PXI chassis mounting (compatible with PXI 1.0/2.0 chassis, e.g., NI PXI-1042); ESD protection (±15 kV air discharge) required; Powered by PXI backplane (no external power supply); Requires 50 Ω coaxial cables for signal output |

| Performance indicators | Waveform update rate: Up to 100 MS/s (real-time); Trigger latency: < 100 ns (external trigger); Frequency accuracy: ±1 ppm (at 25 °C); Amplitude accuracy: ±1% full scale (FS) at 25 °C; Phase noise: -95 dBc/Hz (at 10 kHz offset, 1 MHz carrier) |

| Power requirements & Compatibility | Typical power consumption: 12 W (PXI backplane); Supported OS: Windows 10/11 (32-bit/64-bit), Windows 7 (legacy); Compatible software: NI LabVIEW 2018+, NI-FGEN 18.0+, NI TestStand; Works with NI PCI-MXI-2 (for PCI-PXI integration) and PXI DAQ modules (e.g., NI PXI-6259) |

NI PXI-5412

Product introduction

The NI PXI-5412 is a high-performance PXI arbitrary waveform generator (AWG) developed by National Instruments (NI), engineered for precision analog signal generation in modular test and measurement systems. Unlike interface cards such as the NI PCI-MXI-2 (which bridges PCI and PXI), the NI PXI-5412 is a purpose-built signal source—delivering 100 MS/s sampling rate, 16-bit resolution, and high-fidelity waveforms (up to 40 MHz sine waves) for validating electronic components, sensors, and communication systems.

In PXI-based test setups, the NI PXI-5412 acts as a “precision signal core” for generating custom test stimuli. For example, in a semiconductor chip test rig, it produces arbitrary voltage waveforms (e.g., 10 MHz digital communication signals) to simulate real-world operating conditions for microchips. When paired with a NI PCI-MXI-2 (to connect the PXI chassis to a PCI-based PC), the NI PXI-5412 integrates seamlessly into legacy systems—enabling engineers to leverage its high-frequency capabilities without replacing existing PCI hardware. Its support for advanced modulation (AM, FM, FSK) and low phase noise (< -95 dBc/Hz) makes it ideal for aerospace, automotive, and telecommunications testing, where signal integrity directly impacts test validity.

Core advantages and technical highlights

High-Fidelity Waveforms for Critical Testing: The NI PXI-5412 delivers exceptional signal quality—65 dB SNR, -70 dB THD, and 75 dB SFDR—ensuring generated waveforms closely match real-world signals. This is a critical advantage over low-cost AWGs, which often introduce noise or distortion that invalidates test results. For instance, in a 5G radio frequency (RF) component test, the NI PXI-5412 generates a 25 MHz arbitrary waveform (mimicking 5G base station signals) with < 1% amplitude error and -95 dBc/Hz phase noise—enabling engineers to accurately measure the component’s signal-to-noise ratio and linearity, which are key to 5G performance.

100 MS/s Sampling & Large Waveform Memory: With a 100 MS/s sampling rate and 16 MB standard waveform memory (expandable to 64 MB), the NI PXI-5412 can generate high-frequency, long-duration arbitrary waveforms. This is essential for testing devices with extended response times, such as automotive radar modules. For example, the NI PXI-5412 generates a 10-second, 10 MHz chirp waveform (used in radar distance measurements) by uploading the waveform to its on-board memory via DMA—eliminating PC-to-AWG data transfer latency. The 100 MS/s rate ensures the chirp’s frequency transitions are smooth, avoiding false detections in radar module tests.

Flexible Synchronization with PXI Ecosystem: The NI PXI-5412 supports PXI trigger bus and star trigger, enabling sub-100 ns synchronization with other PXI modules (e.g., NI PXI-6259 DAQ cards, NI PXI-5112 digitizers). This is a key differentiator from standalone AWGs, which lack native PXI synchronization. In an aerospace sensor test rig, for example, the NI PXI-5412 (generating sensor input signals) synchronizes with a NI PXI-6259 (measuring sensor outputs) via PXI trigger—ensuring signal generation and data acquisition align within 50 ns. This timing precision is critical for validating sensor response times, which must meet strict aerospace safety standards.

Advanced Modulation for Communication Testing: Unlike basic AWGs limited to sine/square waves, the NI PXI-5412 supports complex modulation (AM, FM, FSK, PSK) and pulse-width modulation (PWM)—making it ideal for testing communication devices (e.g., Wi-Fi chips, satellite transceivers). For a Wi-Fi 6 chip test, the NI PXI-5412 generates an FSK-modulated signal (2.4 GHz carrier, 100 kHz frequency deviation) that mimics Wi-Fi data packets. Engineers use LabVIEW to program the modulation parameters in real time, adjusting frequency deviation or bit rate to test the chip’s ability to decode different signal conditions—reducing test setup time by 50% compared to manual AWG programming.

Typical application scenarios

In automotive radar module testing, the NI PXI-5412 generates custom chirp waveforms to validate distance measurement accuracy. A test lab uses the NI PXI-5412 in a NI PXI-1042 chassis (connected to a PCI PC via NI PCI-MXI-2) to produce 77 GHz-equivalent chirp signals (downconverted for baseband testing) with 100 MS/s sampling rate. The NI PXI-5412’s low phase noise (-95 dBc/Hz) ensures the chirp’s frequency transitions are linear, while PXI synchronization with a NI PXI-5112 digitizer captures the radar module’s reflected signals. This setup measures the module’s ability to detect objects at 1–100 meters, with the NI PXI-5412’s amplitude accuracy (±1% FS) ensuring test results are repeatable across 1,000+ modules.

In semiconductor validation, the NI PXI-5412 tests analog-to-digital converters (ADCs) for mobile devices. A chip manufacturer uses the NI PXI-5412 to generate a 1 MHz sine wave (5 Vpp into 50 Ω) with -70 dB THD—providing a “gold standard” input for the ADC. The NI PXI-5412’s 16-bit resolution ensures the sine wave has 30.5 µV step increments, enabling precise measurement of the ADC’s integral nonlinearity (INL) and differential nonlinearity (DNL). When paired with a NI PXI-6259 DAQ module (to capture the ADC’s digital output), the NI PXI-5412 helps identify faulty chips with INL exceeding ±1 LSB—critical for meeting mobile device power and performance requirements.

NI PXI-5412

Related model recommendations

NI PCI-MXI-2: A PCI-to-PXI interface card that pairs with the NI PXI-5412. The NI PCI-MXI-2 connects a PCI-based PC to the PXI chassis housing the NI PXI-5412, enabling legacy systems to leverage the AWG’s capabilities without upgrading to a PXI controller.

NI PXI-6259: A PXI DAQ module complementary to the NI PXI-5412. The NI PXI-5412 generates test waveforms, while the NI PXI-6259 acquires device-under-test (DUT) responses—synchronized via PXI trigger for closed-loop testing (e.g., sensor validation).

NI PXI-1042: A 13-slot PXI chassis compatible with the NI PXI-5412. It provides power and synchronization for the NI PXI-5412 and other PXI modules (e.g., digitizers), ideal for large-scale test setups (e.g., automotive radar labs).

NI PXIe-5450: A PXI Express AWG and upgrade of the NI PXI-5412, offering 1.25 GS/s sampling rate and 16-bit resolution. It replaces the NI PXI-5412 for high-frequency applications (e.g., 5G RF testing) requiring speeds beyond 100 MS/s.

NI PXI-5112: A PXI digitizer that works with the NI PXI-5412 for waveform capture. The NI PXI-5412 generates signals, while the NI PXI-5112 (100 MS/s, 14-bit) records them—validating the AWG’s signal quality or capturing DUT outputs (e.g., semiconductor ADC responses).

NI LabVIEW 2018+: Essential software for the NI PXI-5412, providing a graphical environment to design arbitrary waveforms, program modulation, and configure triggers. It includes pre-built VIs for FSK/PSK modulation, reducing development time by 40%.

NI-FGEN Driver: The core driver for the NI PXI-5412, enabling communication between the AWG and software. It optimizes waveform upload via DMA and supports real-time parameter adjustments (e.g., frequency, amplitude) for dynamic testing.

NI TestStand 2022: Automated test software that integrates with the NI PXI-5412. It lets users create test sequences (e.g., ADC linearity testing) and generate reports, ideal for high-volume manufacturing quality control.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing NI PXI-5412, power off the PXI chassis (e.g., NI PXI-1042) and wear an ESD wristband (±15 kV) to protect the module’s precision circuits. Align the NI PXI-5412 with the chassis guide rails, insert firmly until the backplane connector is fully seated, then secure with the chassis front-panel screw. Connect a 50 Ω BNC coaxial cable from the NI PXI-5412’s output to the DUT or signal conditioning equipment—avoid using unshielded cables (which introduce noise). If integrating with a PCI PC, install a NI PCI-MXI-2 in the PC and connect it to the PXI chassis via an MXI-2 cable. Install the latest NI-FGEN driver and LabVIEW, then use NI Measurement & Automation Explorer (MAX) to detect the NI PXI-5412—run the “Signal Integrity Test” to verify waveform quality (e.g., SNR, THD) at 1 MHz.

Maintenance suggestions: Calibrate NI PXI-5412 annually using a NIST-traceable spectrum analyzer (e.g., NI PXIe-5663) to maintain ±1% amplitude accuracy and ±1 ppm frequency accuracy. Inspect the BNC output connector quarterly: clean contacts with isopropyl alcohol (99.9% purity) and a lint-free swab to remove oxidation—corroded contacts degrade signal quality. If the NI PXI-5412 produces distorted waveforms, update its firmware via JTAG or verify the PXI backplane power (ensure stable 5 V/12 V). Avoid exposing the module to temperatures above 55 °C or humidity above 90%—extreme conditions can damage its digital-to-analog converter (DAC) and phase-locked loop (PLL) circuits. Store spare 50 Ω BNC cables in a dry environment to prevent shielding degradation.

Service and guarantee commitment

National Instruments (NI) provides a 2-year standard warranty for the NI PXI-5412, covering defects in materials and workmanship—including the DAC, trigger circuits, and PXI interface. For extended protection, the ServicePlus Premium Plan extends coverage to 5 years, including annual factory calibration (traceable to NIST) for signal quality parameters (SNR, THD, frequency accuracy), priority technical support (2-hour response time for aerospace/automotive customers), and expedited repairs (turnaround time < 3 business days).

NI’s global technical team includes AWG specialists, offering 24/7 support for the NI PXI-5412—assisting with waveform design, modulation programming, and synchronization troubleshooting (e.g., resolving PXI trigger latency). Customers gain free access to exclusive resources: application notes on 5G waveform generation with the NI PXI-5412, LabVIEW example code for FSK modulation, and a user community for sharing test best practices. For out-of-warranty repairs, NI’s Precision AWG Restore Service replaces aged components (e.g., DAC, PLL) and verifies all performance metrics—restoring the NI PXI-5412 to factory specs. This commitment reflects NI’s confidence in the module’s durability and dedication to supporting users’ high-precision test workflows.