Description

NI PXI-6608 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXI-6608 |

| Manufacturer | National Instruments |

| Product Category | PXI Counter/Timer Module |

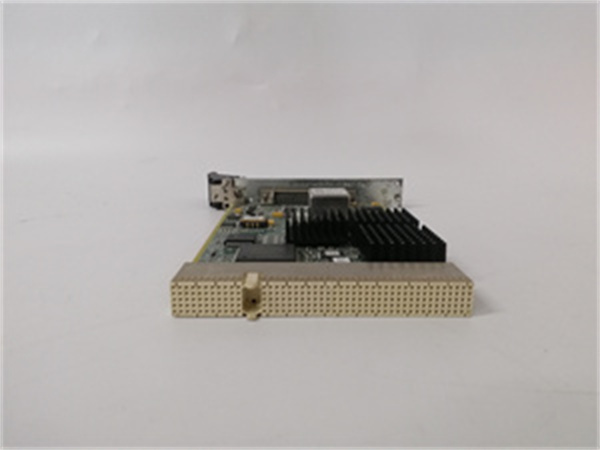

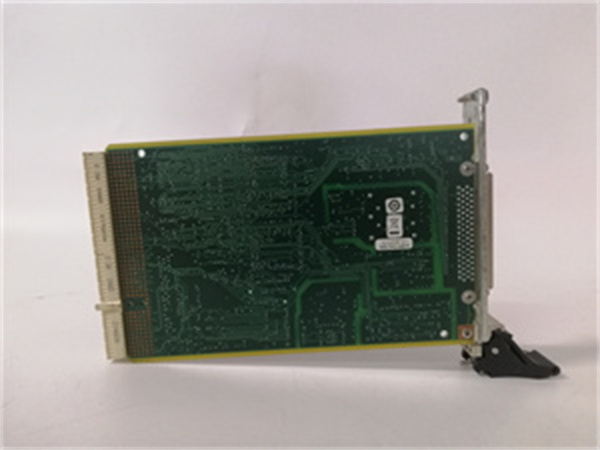

| Form Factor | 3U PXI |

| Slot Requirement | 1 PXI slot |

| Counters/Timers | 8 independent 32-bit counters |

| Time Base Options | Internal (10 MHz, 20 MHz), external (up to 100 MHz) |

| Maximum Count Rate | 80 MHz (with 20 MHz time base), 100 MHz (with external time base) |

| Counter Modes | Frequency measurement, period measurement, pulse width measurement, event counting, pulse generation, PWM (Pulse Width Modulation), encoder position measurement, synchronized triggering |

| Input/Output Channels | 16 digital I/O lines (shared with counter inputs/outputs) |

| Input Voltage Range | TTL/CMOS compatible (0 V to 5 V; logic low: ≤0.8 V; logic high: ≥2.0 V) |

| Output Voltage Range | TTL/CMOS compatible (0 V to 5 V; logic low: ≤0.4 V; logic high: ≥2.4 V) |

| Input/Output Current | ±24 mA (sink/source) |

| Triggering Options | PXI trigger lines (8), PXI Star trigger, software triggers |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -40 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 100 mm (width) x 160 mm (depth) x 37 mm (height) |

| Weight | 320 g |

| Compliance Standards | CE, UL, CSA, FCC Part 15 Class A |

| Software Compatibility | LabVIEW, LabWindows/CVI, .NET, C/C++, NI-DAQmx |

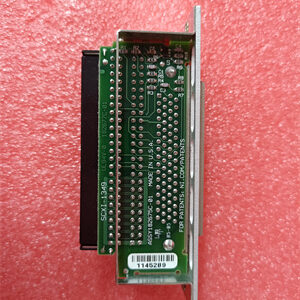

| Connector Type | 2 x 50-pin DSUB (female) |

NI PXI-6608

Product Introduction

The NI PXI-6608 is a high-performance 3U PXI counter/timer module designed to handle precise timing, counting, and synchronization tasks in automated test systems, industrial control, and research applications. Equipped with 8 independent 32-bit counters, it offers versatile functionality for measuring frequencies, periods, pulse widths, generating custom pulses, and synchronizing multi-module systems.

This module integrates seamlessly with PXI chassis such as the PXI-1031, leveraging the PXI bus and trigger lines for tight synchronization with other modules like the PXI-6527 digital I/O module or PXI-4462 dynamic signal acquisition module. Its flexible time base options (internal and external) and support for various counter modes make it suitable for a wide range of applications, from high-speed event counting in manufacturing to precise pulse generation in robotics. Whether deployed in semiconductor testing, aerospace simulations, or industrial automation, the PXI-6608 delivers reliable, high-accuracy timing and counting performance.

Core Advantages and Technical Highlights

Multi-Counter Flexibility

With 8 independent 32-bit counters, the PXI-6608 enables parallel execution of multiple timing and counting tasks. Each counter can be configured in a different mode, allowing simultaneous frequency measurement, pulse generation, and event counting—eliminating the need for multiple single-function modules. For example, in a production line test station, one counter can measure the frequency of a sensor signal, another can generate a PWM signal to control a motor, and a third can count the number of parts passing a checkpoint.

High-Speed Counting and Timing

The module supports maximum count rates up to 100 MHz with an external time base, making it ideal for high-speed applications such as measuring fast-switching signals in communication systems or counting high-frequency events in particle physics experiments. Even with the internal 20 MHz time base, it achieves 80 MHz counting, ensuring accuracy in time-critical measurements where nanosecond-level precision is required.

Advanced Synchronization Capabilities

The PXI-6608 leverages PXI trigger lines (8) and the PXI Star trigger for multi-module synchronization, enabling precise coordination with other PXI devices. This is critical in large-scale systems, such as automotive test benches, where the module can trigger synchronized data acquisition across multiple PXI-4462 DSA modules and control signals from the PXI-6527 digital I/O module. The ability to share a common external time base further enhances synchronization across distributed systems.

Versatile Operating Modes

The module supports a wide range of counter modes to address diverse application needs:

Frequency/period measurement: For characterizing signal generators or rotating machinery speeds.

Pulse width measurement: For analyzing duty cycles in power electronics or sensor signals.

Pulse generation: For creating custom waveforms to test actuators or communication interfaces.

Encoder position measurement: For tracking linear or rotational motion in robotics or CNC machines.

Event counting: For tallying production units, particle impacts, or other discrete events.

Typical Application Scenarios

Industrial Automation and Control

In factory automation, the PXI-6608 synchronizes production line operations by generating precise timing signals for conveyor belts, robotic arms, and inspection cameras. It can count the number of products passing a sensor (event counting) while generating PWM signals to control motor speeds, ensuring consistent throughput. When paired with the PXI-6527, it triggers digital I/O signals to activate sorting mechanisms based on part counts or timing thresholds.

Aerospace and Defense Testing

In aerospace testing, the module measures the frequency and pulse width of signals from aircraft sensors (e.g., accelerometers, gyroscopes) to validate performance under extreme conditions. It can generate synchronized trigger signals for data acquisition modules like the PXI-4462, ensuring vibration and acoustic data are captured at precise time intervals. In radar system testing, it counts and times pulses to verify signal integrity and timing accuracy.

Semiconductor Manufacturing

In semiconductor wafer testing, the PXI-6608 generates precise clock signals to synchronize test fixtures and measure the response times of integrated circuits (ICs). It counts the number of valid data bits from a DUT (device under test) while generating pulses to simulate input signals, helping validate IC performance at different frequencies. When combined with the PXI-2510 switch module, it coordinates signal routing across multiple test points, improving test efficiency.

NI PXI-6608

Related Model Recommendations

NI PXI-1031: A 5-slot PXI chassis that houses the PXI-6608 and other modules, providing a compact platform for synchronized timing systems. For larger setups, the PXI-1042 (18-slot) offers expanded capacity.

NI PXI-6527: A digital I/O module that pairs with the PXI-6608 for combined timing and control. The PXI-6608 triggers digital signals via the PXI-6527 to control relays, solenoids, or test fixtures.

NI PXI-4462: A dynamic signal acquisition module that uses triggers from the PXI-6608 to synchronize data capture with external events (e.g., vibration spikes or acoustic pulses).

NI PXI-8106: A PXI controller that configures and monitors the PXI-6608 via NI-DAQmx, executing LabVIEW-based algorithms to adjust timing parameters in real time.

NI BNC-2120: A terminal block with screw terminals that simplifies connections between external sensors, actuators, and the PXI-6608’s DSUB connectors, featuring LED indicators for signal status.

Installation, Commissioning, and Maintenance

Installation Steps

Module Insertion: Power off the PXI chassis (e.g., PXI-1031). Insert the PXI-6608 into an available slot, ensuring full seating in the backplane. Secure with front-panel screws to prevent movement during operation.

Wiring Connection: Use the BNC-2120 terminal block or custom cables to connect external signals (e.g., sensors, triggers) to the module’s 50-pin DSUB connectors. Refer to the pinout diagram to map counter inputs/outputs to external devices, ensuring correct signal polarity.

Software Setup: Install NI-DAQmx drivers on the PXI controller. Launch NI Measurement & Automation Explorer (MAX) to verify module detection, then configure counter modes, time bases, and trigger sources via software.

Commissioning

Counter Functionality Test: Configure a counter in frequency measurement mode and connect a calibrated signal generator (e.g., 1 MHz) to verify accurate reading. Repeat for pulse generation mode by generating a 10 kHz pulse train and measuring it with an oscilloscope.

Synchronization Validation: Use the PXI Star trigger to synchronize the PXI-6608 with a PXI-6527 module. Verify that digital I/O signals from the PXI-6527 are triggered precisely at the counter’s specified intervals, using a logic analyzer to check timing offsets.

High-Speed Performance Check: Test the module’s maximum count rate by inputting a 100 MHz signal (with an external time base) and confirming accurate counting. Validate pulse width measurement accuracy with a known narrow pulse (e.g., 10 ns) to ensure precision at high speeds.

Maintenance Tips

Connector Inspection: Regularly check the 50-pin DSUB connectors for bent pins, corrosion, or debris. Clean with compressed air or a soft brush; avoid liquid cleaners that may damage internal components.

Time Base Calibration: Periodically verify the accuracy of the internal time base using a calibrated frequency standard. For critical applications, use an external oven-controlled crystal oscillator (OCXO) for long-term stability.

Cable Management: Ensure cables connecting to the module are shielded and securely fastened to minimize electromagnetic interference (EMI), which can corrupt high-speed timing signals. Route cables away from power lines or noise sources.

Software Updates: Keep NI-DAQmx drivers up to date to access bug fixes and performance improvements for counter/timer functionality. Verify compatibility with the operating system and other PXI modules.

Service and Guarantee Commitment

The NI PXI-6608 is backed by a 2-year standard warranty covering defects in materials and workmanship. National Instruments’ global technical support team provides 24/7 assistance for installation, troubleshooting, and software integration via phone, email, and online resources.

NI offers calibration services to ensure the module’s time bases and counter measurements meet published specifications, with traceability to NIST standards. Extended warranty and calibration plans are available for customers requiring long-term support. Engineered for reliability, the PXI-6608 delivers consistent performance in high-precision timing and counting applications, backed by NI’s commitment to quality and customer success.