Description

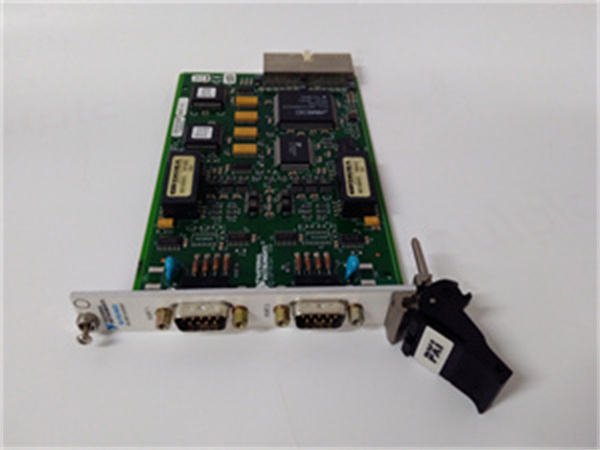

NI PXI-8423 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PXI-8423 |

| Manufacturer | NI |

| Product category | PXI Serial Interface Module |

| Number of Ports | 2 (isolated RS-232/422/485) |

| Communication Standards | RS-232, RS-422, RS-485 |

| Data Transfer Rates | Up to 921.6 kbps |

| Isolation Rating | 2500 Vrms (transient overvoltage protection) |

| RS-232 Signals | TXD, RXD, RTS, CTS, DTR, DSR, DCD, RI |

| RS-422/485 Signals | TX+, TX-, RX+, RX-, RTS+, RTS- (for direction control) |

| RS-485 Termination | Software-selectable 120 Ω |

| RS-485 Bias Resistors | Software-selectable |

| PXI Bus Compatibility | PXI, CompactPCI |

| Form Factor | 3U PXI module |

| Operating Temperature | 0 °C to 55 °C |

| Weight | 13 oz (369 g) |

| Part Numbers | 778035-01 (Standard) |

| Software Compatibility | LabVIEW, LabWindows/CVI, C/C++,.NET, VISA |

| Connector Type | 2 DB-9 male connectors |

NI PXI-8423

Product introduction

The NI PXI-8423 is a dual-port isolated serial interface module designed to enable reliable serial communication in industrial automation and test systems. As part of NI’s PXI connectivity portfolio, this 3U module integrates seamlessly into PXI and CompactPCI chassis, providing robust RS-232/422/485 communication for connecting to legacy and modern serial devices.

The PXI-8423 supports multiple serial standards, making it versatile for diverse applications requiring communication with sensors, actuators, programmable logic controllers (PLCs), and other serial-enabled equipment. Its 2500 Vrms isolation protects both the module and connected devices from voltage transients, a critical feature in industrial environments with electrical noise. With data transfer rates up to 921.6 kbps, it balances speed and reliability, while software-selectable termination and bias resistors for RS-485 simplify configuration for different bus lengths. Whether used in factory automation or aerospace test systems, the PXI-8423 serves as a robust bridge between PXI-based control systems and serial devices.

Core advantages and technical highlights

Industrial-Grade Isolation: The NI PXI-8423 features 2500 Vrms isolation, which protects against ground loops and voltage spikes common in industrial environments. This isolation prevents damage to the PXI chassis and other modules from transient overvoltages, ensuring system reliability in harsh conditions. In applications like factory floors where electrical noise is prevalent, this feature maintains signal integrity and reduces communication errors.

Multi-Standard Flexibility: Supporting RS-232, RS-422, and RS-485, the PXI-8423 eliminates the need for multiple interface modules. RS-232 is ideal for short-distance communication with devices like barcode scanners, while RS-422 (point-to-multipoint) and RS-485 (multi-drop) enable longer cable runs (up to 1200 meters for RS-485) in distributed systems. This versatility allows engineers to connect to diverse serial devices without redesigning the system.

RS-485 Optimization: The PXI-8423 includes software-selectable 120 Ω termination resistors and bias resistors for RS-485 networks. Termination resistors prevent signal reflections in long cables, while bias resistors keep the bus in a known state when idle, reducing data corruption. These features simplify setup for different network topologies, from simple point-to-point connections to complex multi-node systems with up to 32 devices.

Seamless PXI Integration: As a PXI module, the PXI-8423 leverages the PXI backplane for power and communication, eliminating external power supplies and simplifying system cabling. It integrates with NI’s software ecosystem, including VISA (Virtual Instrument Software Architecture) for consistent programming across different interface types. This integration allows synchronization with other PXI modules (such as data acquisition or motion control) via PXI trigger lines, enabling coordinated operations in automated test sequences.

Typical application scenarios

In factory automation, the NI PXI-8423 connects PXI-based control systems to RS-485 networks of sensors and actuators. For example, in a packaging line, it can communicate with temperature sensors, pressure transducers, and motor drives distributed along the line. The module’s isolation protects the control system from electrical noise generated by motors, while its RS-485 support enables long cable runs between devices. Integration with LabVIEW allows engineers to develop custom monitoring software that collects data from serial devices and triggers actions (like adjusting conveyor speed) based on sensor readings.

In aerospace and defense test systems, the PXI-8423 interfaces with legacy avionics components that use RS-232 or RS-422. During aircraft subsystem testing, it can send commands to and receive data from navigation sensors, communication radios, and flight control units. The module’s reliable communication ensures test sequences run without interruptions, while its isolation prevents interference between sensitive test equipment and the avionics under test. The ability to synchronize with PXI data acquisition modules ensures time-stamped correlation between serial data and other measurements (like voltage or current).

In building automation, the PXI-8423 integrates with RS-485-based BACnet or Modbus networks of HVAC, lighting, and security systems. A PXI controller using the module can monitor temperature, humidity, and energy usage across a facility, then send commands to adjust settings (e.g., lowering thermostat setpoints during unoccupied hours). The module’s dual ports allow separate communication with high-priority systems (like fire alarms) and general building systems, ensuring critical messages aren’t delayed.

NI PXI-8423

Related model recommendations

NI PXI-8422: A 2-port non-isolated serial module in the same family, offering lower cost for applications where isolation isn’t required (e.g., laboratory environments with controlled electrical conditions). It shares the same software compatibility as the PXI-8423.

NI PXI-8431/8: An 8-port RS-232 module, ideal for systems requiring more serial ports than the PXI-8423. It’s suitable for test racks with multiple serial devices, such as telecom equipment testing with numerous modems or routers.

NI USB-8451: A USB-based I2C/SPI interface module that complements the PXI-8423 in mixed-protocol systems. While the PXI-8423 handles serial communication, the USB-8451 connects to I2C/SPI sensors, expanding the system’s connectivity options.

NI PXI-6529: A digital I/O module that works with the PXI-8423 to add parallel communication capabilities. In industrial systems needing both serial and parallel interfaces (e.g., connecting to older PLCs with parallel ports), this combination provides comprehensive connectivity.

NI PXIe-8431/4: A PXI Express module with 4 isolated RS-232/422/485 ports, offering higher bandwidth and faster data transfer than the PXI-8423. It’s an upgrade for high-throughput systems, such as automated test equipment requiring simultaneous communication with multiple high-speed serial devices.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXI-8423, power off the PXI or CompactPCI chassis and ensure it has an available 3U slot. Inspect the module’s connectors for bent pins or damage, and clean the chassis slot with compressed air if dusty. Use anti-static precautions (wrist strap, grounded work surface) when handling the module to prevent electrostatic damage. Verify that connected devices match the module’s supported standards (RS-232/422/485) and that cable lengths comply with standard specifications (e.g., ≤15 meters for RS-232, ≤1200 meters for RS-485).

Commissioning: Install NI-VISA (version 5.0 or later) on the host controller to enable communication with the PXI-8423. After inserting the module into the chassis, launch NI Measurement & Automation Explorer (MAX) to verify detection and configure port settings (baud rate, parity, flow control). Use MAX’s test panel to send and receive test messages, confirming communication with connected devices. For RS-485 networks, enable termination and bias resistors via software based on cable length (termination recommended for cables >10 meters). Test isolation integrity using a multimeter to check resistance between module grounds and connected device grounds (should read >1 MΩ).

Maintenance suggestions: Periodically inspect the PXI-8423‘s DB-9 connectors for corrosion or bent pins, especially in industrial environments with high humidity or dust. Clean connectors with isopropyl alcohol and a soft cloth if needed. Monitor communication error rates using NI-VISA diagnostics to detect issues like loose cables or signal degradation. For RS-485 networks, check for bus contention (multiple devices transmitting simultaneously) which can cause data errors. Update NI-VISA software regularly to access bug fixes and improved compatibility with new operating systems. If isolation failure is suspected (e.g., frequent communication errors in noisy environments), contact NI service for testing.

Service and guarantee commitment

NI provides a 2-year warranty for the PXI-8423, covering manufacturing defects and ensuring replacement or repair of faulty modules at no cost during this period. The module’s isolation components are covered under this warranty, reflecting NI’s confidence in their long-term reliability.

Technical support is available via phone, email, and online forums, with specialists experienced in serial communication protocols assisting with configuration, troubleshooting, and system integration. The NI website offers detailed user manuals, application notes on serial network design, and example code for LabVIEW and other programming environments. For customers requiring calibration or recertification, NI Service Centers provide traceable calibration services to ensure the PXI-8423 meets original performance specifications. This commitment to quality and support ensures the module delivers reliable serial communication throughout its operational lifecycle.