Description

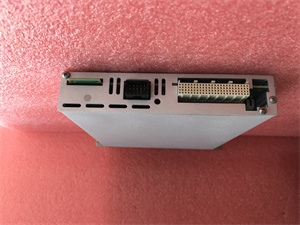

NI PXIe-4112 Product Description

Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXIe-4112 |

| Manufacturer | National Instruments |

| Product Category | PXIe Source Measure Unit (SMU) |

| Form Factor | 3U PXIe |

| Slot Requirement | 1 PXIe slot |

| Channels | 1 channel |

| Voltage Range | ±20 V |

| Current Range | ±1 A (DC), ±3 A (pulsed) |

| Voltage Resolution | 16 bits |

| Current Resolution | 16 bits |

| Voltage Accuracy | ±(0.015% of reading + 0.005% of range) |

| Current Accuracy | ±(0.02% of reading + 0.01% of range) |

| Maximum Power | 20 W (DC), 60 W (pulsed) |

| Measurement Modes | Voltage, current, resistance (4-wire), power |

| Sweep Capabilities | Voltage, current, power sweeps with programmable points and timing |

| Compliance Protection | Voltage and current compliance limits |

| Interface | PXIe 2.0 (x1 lane) |

| Operating Temperature | 0 °C to 55 °C |

| Storage Temperature | -40 °C to 70 °C |

| Humidity Range | 5% to 95% non-condensing |

| Dimensions | 100 mm (width) x 160 mm (depth) x 37 mm (height) |

| Weight | 380 g |

| Compliance Standards | CE, UL, CSA, FCC Part 15 Class A |

| Software Compatibility | LabVIEW, LabWindows/CVI, .NET, C/C++, NI-DCPower |

NI PXIe-4112

Product Introduction

The NI PXIe-4112 is a high-performance 3U PXIe Source Measure Unit (SMU) designed for precise voltage sourcing and current/voltage measurement in electronic device testing and characterization. As a key component in National Instruments’ PXIe modular test ecosystem, it combines a flexible power source with a sensitive measurement instrument, making it ideal for applications such as semiconductor device testing, sensor calibration, and materials science research.

This module integrates seamlessly with PXIe chassis like the PXIe-1073, leveraging the high-speed PXIe bus for fast data transfer and synchronization with other modules—including the PXI-8461 for CAN/LIN communication in automated test systems. Its ability to source and measure both voltage and current with high accuracy and resolution enables comprehensive testing of components ranging from diodes and transistors to complex integrated circuits. Whether deployed in production test stations or research laboratories, the PXIe-4112 delivers reliable performance for demanding low to medium power applications.

Core Advantages and Technical Highlights

Versatile Sourcing and Measurement

The PXIe-4112 functions as both a precision power source and a sensitive meter, eliminating the need for separate instruments. It can source voltages up to ±20 V and currents up to ±1 A (DC) or ±3 A (pulsed), while simultaneously measuring voltage, current, resistance (via 4-wire sensing), and power. This versatility is particularly valuable in semiconductor testing, where it can bias a device with a specific voltage and measure the resulting current to characterize parameters like leakage current or gain.

High Accuracy and Resolution

With 16-bit resolution for both voltage and current, and accuracy specifications as tight as ±(0.015% of reading + 0.005% of range) for voltage, the PXIe-4112 ensures precise measurements even for low-level signals. For example, when testing a photodiode, it can accurately measure microampere-level currents generated by light exposure, providing reliable data for characterizing sensor sensitivity. The 4-wire resistance measurement capability minimizes lead resistance errors, critical for testing low-resistance components like shunt resistors.

Pulsed Power Capability

The module’s ability to deliver pulsed currents up to 3 A (with 60 W pulsed power) makes it suitable for testing devices that require short-duration high-current inputs, such as power transistors or batteries. Pulsed operation reduces self-heating in the DUT (device under test) and the SMU itself, ensuring more accurate measurements and preventing damage to heat-sensitive components.

Fast Sweeping and Automation

The PXIe-4112 supports programmable voltage, current, and power sweeps with configurable points, intervals, and compliance limits. This allows engineers to automate complex test sequences—for example, sweeping the voltage across a diode from 0 V to 10 V and measuring the resulting current to generate an I-V curve. The PXIe bus enables fast data transfer, allowing sweep data to be logged to a controller (like the PXI-8186) for real-time analysis, reducing test cycle time in production environments.

Typical Application Scenarios

Semiconductor Device Characterization

In semiconductor labs, the PXIe-4112 is used to characterize discrete components and integrated circuits. It can measure the I-V characteristics of diodes, MOSFETs, and BJTs, determining parameters like threshold voltage, on-resistance, and breakdown voltage. When paired with the PXI-2510 switch module, it can test multiple devices sequentially, automating the characterization process for high-throughput testing.

Sensor Calibration

The module is ideal for calibrating a wide range of sensors, including temperature sensors (e.g., thermistors), pressure sensors, and light sensors. For example, it can source a known current to a thermistor and measure the resulting voltage to determine its resistance-temperature curve, then compare it to a reference to generate calibration coefficients. The high accuracy of the PXIe-4112 ensures that calibrated sensors meet tight performance specifications.

Battery and Power Device Testing

In battery testing, the PXIe-4112 can source current to charge a battery cell and measure its voltage to track charging curves, or discharge the battery while monitoring current to analyze capacity. For power devices like voltage regulators, it can test line and load regulation by varying the input voltage or output current and measuring the output voltage stability. The pulsed current capability allows testing of power switches under high-current conditions without overheating.

NI PXIe-4112

Related Model Recommendations

NI PXIe-1073: A 14-slot PXIe chassis that houses the PXIe-4112 and other modules, providing a high-performance platform for automated test systems. Its hybrid backplane supports both PXIe and legacy PXI modules.

NI PXI-8186: A PXI controller that manages the PXIe-4112, executing test sequences, logging measurement data, and analyzing results. It integrates with LabVIEW to create custom test interfaces.

NI PXI-2510: A matrix switch module that, when paired with the PXIe-4112, enables the SMU to test multiple DUTs without manual reconnection, increasing test efficiency in production environments.

NI PXI-6608: A counter/timer module that synchronizes the PXIe-4112 with other instruments, ensuring precise timing of voltage/current sweeps or measurement triggers in coordinated test sequences.

NI-DCPower: Software that provides a programming interface for the PXIe-4112, simplifying the configuration of sourcing and measurement parameters, sweep setup, and data acquisition.

Installation, Commissioning, and Maintenance

Installation Steps

Module Insertion: Power off the PXIe chassis (e.g., PXIe-1073). Insert the PXIe-4112 into an available PXIe slot, ensuring the module is fully seated in the backplane. Secure with front-panel screws to prevent movement during operation.

Connections: Connect the DUT to the module’s front-panel terminals using appropriate test leads. For 4-wire resistance measurements, use separate sense and force leads to minimize lead resistance errors.

Software Setup: Install NI-DCPower drivers on the PXI controller (e.g., PXI-8186). Launch NI Measurement & Automation Explorer (MAX) to verify the module is detected and configure basic settings like current and voltage limits.

Commissioning

Calibration Verification: Use a calibrated reference standard (e.g., a precision resistor or voltage source) to verify the module’s accuracy. For example, measure a 1 kΩ standard resistor in 4-wire mode and confirm the reading is within the specified accuracy range.

Sourcing and Measurement Test: Test voltage sourcing by setting a 5 V output and measuring it with a calibrated DMM (like the PXI-4071). Verify current measurement accuracy by passing a known current (e.g., 100 mA) through a shunt resistor and comparing the SMU’s reading to the expected value.

Sweep Functionality Check: Configure a voltage sweep from 0 V to 10 V with 100 points and verify that the module generates the correct voltages and logs the corresponding current measurements. Check that the sweep completes within the expected time frame, ensuring the PXIe bus is transferring data efficiently.

Maintenance Tips

Terminal Inspection: Regularly inspect the front-panel terminals for corrosion, damage, or loose connections. Clean terminals with a soft, dry cloth if necessary, and ensure test leads are in good condition.

Calibration Schedule: Calibrate the PXIe-4112 annually (or per application requirements) using NI’s accredited calibration services to maintain measurement accuracy and traceability to NIST standards.

Overload Protection: Avoid exceeding the module’s voltage, current, or power limits to prevent damage. Configure appropriate compliance limits in software to protect both the SMU and the DUT.

Thermal Management: Ensure the PXIe chassis cooling system is functioning properly, as the PXIe-4112 can generate heat during high-power operation. Monitor module temperature via MAX to prevent overheating.

Service and Guarantee Commitment

The NI PXIe-4112 is backed by a 2-year standard warranty covering defects in materials and workmanship. National Instruments’ global technical support team provides 24/7 assistance for installation, troubleshooting, and software integration via phone, email, and online resources.

NI offers calibration and repair services to ensure the module meets original performance specifications. Extended warranty plans are available for customers requiring long-term support. Engineered for reliability in demanding test environments, the PXIe-4112 delivers consistent sourcing and measurement performance, backed by NI’s commitment to quality and customer success.