Description

1. Detailed Parameter Table

| Parameter Name | Parameter Value |

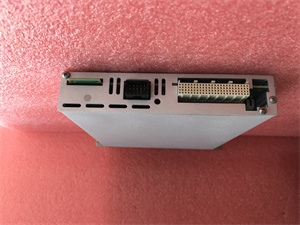

| Product Model | PXIe-6124 |

| Manufacturer | National Instruments (NI) |

| Product Category | High-Speed Multifunction PXIe DAQ Module |

| Analog Input Channels | 16 single-ended / 8 differential |

| Analog Input Resolution | 16-bit |

| Analog Input Ranges | ±10 V, ±5 V, ±2.5 V, ±1 V, ±0.5 V, 0-10 V, 0-5 V, 0-2 V, 0-1 V |

| Maximum Sampling Rate | 2 MS/s (single channel), 2 MS/s (multichannel, with channel scanning) |

| Analog Output Channels | 2 |

| Analog Output Resolution | 16-bit |

| Analog Output Ranges | ±10 V |

| Analog Output Update Rate | 2.86 MS/s |

| Digital I/O Lines | 16 lines (configurable as input or output) |

| Counter/Timers | 24-bit, 80 MHz (2 counters) |

| Triggering | Analog and digital triggering; support for PXIe trigger bus and star trigger |

| DMA Channels | 3 |

| FIFO Buffer Size | 8 kS (analog input), 2 kS (analog output) |

| Connector Type | 68-pin VHDCI |

| Operating Temperature Range | 0 to 55 °C |

| Storage Temperature Range | -20 to 70 °C |

| Humidity Range | 5 to 95% non-condensing |

| Power Consumption | 5 W typical |

| Software Compatibility | LabVIEW, LabWindows/CVI, Measurement Studio, Visual Studio (C/C++, C#), Python |

NI PXIe-6124

2. Product Introduction

The NI PXIe-6124 is a high-performance multifunction data acquisition (DAQ) module designed for the PXIe platform, engineered to excel in applications requiring fast, precise signal acquisition and generation. As part of NI’s M Series, it combines high-speed sampling with versatile I/O capabilities, making it a cornerstone of test and measurement systems in industries ranging from automotive to aerospace.

Featuring 16 single-ended or 8 differential analog input channels, the PXIe-6124 delivers 16-bit resolution and a maximum sampling rate of 2 MS/s—ideal for capturing transient signals, such as voltage spikes in power electronics or high-frequency vibrations in mechanical systems. Its 2 analog output channels, with 16-bit resolution and a 2.86 MS/s update rate, enable precise generation of control waveforms, from simple DC levels to complex sine waves.

The module’s 16 digital I/O lines and 2 high-speed counter/timers add flexibility, supporting tasks like event counting, pulse generation, and digital control. Integration with the PXIe trigger bus ensures seamless synchronization with other modules, such as signal generators or oscilloscopes, making it a versatile choice for multi-module test setups.

3. Core Advantages and Technical Highlights

High-Speed Sampling for Transient Signals

The PXIe-6124’s 2 MS/s sampling rate (sustained across all channels) enables accurate capture of fast-changing signals. In power electronics testing, for example, it can sample switching transients in inverters at 2 MS/s, capturing voltage spikes as short as 500 ns—critical for analyzing efficiency and EMI (electromagnetic interference) in motor drives. This speed ensures no detail is missed in dynamic phenomena like combustion pressure pulses in engine testing.

Low Noise and High Precision

With 16-bit resolution and low input noise (11 µV peak-to-peak), the PXIe-6124 delivers precise measurements even for small signals. In biomedical research, it can detect millivolt-level ECG signals from electrodes, while in strain gauge applications, it resolves microstrain variations in structural materials. The module’s selectable input ranges (down to ±0.5 V) eliminate the need for external amplification in many cases, simplifying system design.

Integrated Synchronization

Support for PXIe trigger lines and star trigger ensures the PXIe-6124 synchronizes with other modules to within nanoseconds. In a multi-channel acoustic testing setup, this means signals from 8 microphones are captured simultaneously, enabling accurate sound localization. When paired with a PXIe-6672T timing module, it can synchronize across distributed systems, such as in aerospace wind tunnel tests where data from hundreds of sensors must be time-aligned.

Versatile I/O for System Integration

The combination of analog I/O, digital lines, and counters in one module reduces system complexity. In automated test equipment (ATE), the PXIe-6124 can generate analog stimuli via its outputs, measure DUT (device under test) responses with its inputs, control test fixtures via digital lines, and count encoder pulses to track DUT position—all without needing separate modules. This integration saves chassis space and reduces wiring complexity.

4. Typical Application Scenarios

Automotive Powertrain Testing

In automotive engineering, the PXIe-6124 monitors engine and transmission signals during dyno testing. It samples crankshaft position (via hall sensors) and fuel injector voltages at 2 MS/s, capturing transient behavior during acceleration. The module’s analog outputs generate simulated sensor signals to test ECU (engine control unit) response, while digital lines trigger data logging when critical thresholds (e.g., overheating) are reached. This enables engineers to optimize fuel efficiency and emissions.

Semiconductor Device Characterization

Semiconductor labs use the PXIe-6124 to characterize analog ICs (integrated circuits). It measures voltage gain, bandwidth, and distortion in op-amps by generating input signals (via analog outputs) and sampling the amplified output. The 2 MS/s rate allows testing of high-speed ADCs (analog-to-digital converters) up to 1 MSPS, while digital lines control multiplexers to switch between test points on the IC wafer.

Structural Health Monitoring

In civil engineering, the PXIe-6124 monitors vibrations in bridges and buildings. It connects to accelerometers placed at critical points, sampling at 1 MS/s to detect resonant frequencies and micro-fracture-induced vibrations. The module logs data to a PXIe-8820 controller, which runs real-time algorithms to identify structural weaknesses. Digital lines trigger alarms if vibrations exceed safe thresholds, enabling proactive maintenance.

Aerospace Avionics Testing

Aerospace test labs use the PXIe-6124 to validate avionics systems, such as flight control sensors. It simulates altitude and airspeed signals (via analog outputs) to test autopilot response, while sampling gyroscope and accelerometer data at 2 MS/s to verify accuracy. The module’s counters track pulse-width modulated (PWM) signals from actuators, ensuring they respond correctly to control commands—critical for certifying flight-worthy systems.

NI PXIe-6124

5. Related Model Recommendations

PXIe Chassis

The PXIe-6124 performs best in high-bandwidth PXIe chassis like the PXIE-1085 (18-slot) or PXIE-1071 (7-slot). These chassis provide the PCIe Gen 3 backplane needed to leverage the module’s data transfer capabilities, supporting multi-module setups with DAQ, RF, and switching modules.

Timing and Synchronization Modules

Pair with the PXIe-6672T timing module for distributed synchronization. This combination ensures the PXIe-6124 and other modules (e.g., PXIe-5663 RF analyzers) operate with sub-100 ps timing skew—essential for multi-domain testing (e.g., combining electrical and RF measurements).

Signal Conditioning Modules

For sensor-specific conditioning, use the SCXI-1125 (isolated analog input) with the PXIe-6124 to measure high-voltage signals (up to 300 V) safely, or the SCXI-1102B for thermocouple temperature measurements. These modules amplify and filter signals, ensuring compatibility with the DAQ’s input ranges.

Controllers and Software

The PXIe-7975 embedded controller provides the processing power to handle data from the PXIe-6124 in real time. Complement with LabVIEW for graphical programming of acquisition logic and DIAdem for post-test data analysis, enabling end-to-end test workflows.

6. Installation, Commissioning and Maintenance Instructions

Installation Preparation

Power off the PXIe chassis before installing the PXIe-6124. Use an anti-static wristband to prevent ESD damage. Align the module with the chassis guide rails, ensuring the PCIe connector seats fully, then secure with front-panel screws. Connect sensors or signal sources via a 68-pin VHDCI cable (e.g., SHC68-68-EPM) to a terminal block (e.g., TB-2706) for easy wiring. Verify signal levels match the module’s input ranges to avoid overload.

Commissioning Steps

Power on the chassis and launch NI MAX to detect the PXIe-6124. Install the latest NI-DAQmx driver (2023 Q3 or newer) for full functionality. Configure channels (single-ended/differential, input range) and trigger settings via MAX or software. Calibrate using a precision DMM (e.g., PXIe-4071) to verify accuracy—apply known voltages and confirm readings are within ±0.1% of full scale. Test with a function generator, sampling a 100 kHz sine wave to validate the 2 MS/s rate.

Maintenance Suggestions

Inspect the module quarterly for loose connectors or dust buildup; clean vents with compressed air. Check calibration annually using NI’s calibration service to maintain measurement accuracy. If noise increases, verify grounding—ensure the module, sensors, and chassis share a common ground. Update firmware via NI Update Service to address bugs and improve compatibility with new modules. For persistent issues, refer to the user manual or contact NI technical support.

7. Service and Guarantee Commitment

NI backs the PXIe-6124 with a 3-year standard warranty, covering defects in materials and workmanship. During the warranty period, NI provides technical support via online resources, email, and phone, with experts assisting in setup, synchronization, and software integration. For out-of-warranty modules, NI offers repair services and calibration (ISO 17025 accredited) to extend operational life. The module is supported by NI’s global service network, ensuring timely access to replacement parts and expertise—critical for minimizing downtime in production and research environments.