Description

1. Detailed Parameter Table

| Parameter Name | Parameter Value |

| Product Model | PXIe-8880 |

| Manufacturer | National Instruments (NI) |

| Product Category | High-Performance Embedded Controller for PXI Express Systems |

| Processor | Intel Xeon E5-2618L v3, 8-core, 2.3 GHz (up to 3.4 GHz in single-core Turbo Boost mode) |

| Memory | Standard: 8 GB (1 x 8 GB DIMM), triple-channel 1866 MHz DDR4 RAM; Maximum: 24 GB |

| Storage | Standard: 480 GB Solid-State Drive (SSD) |

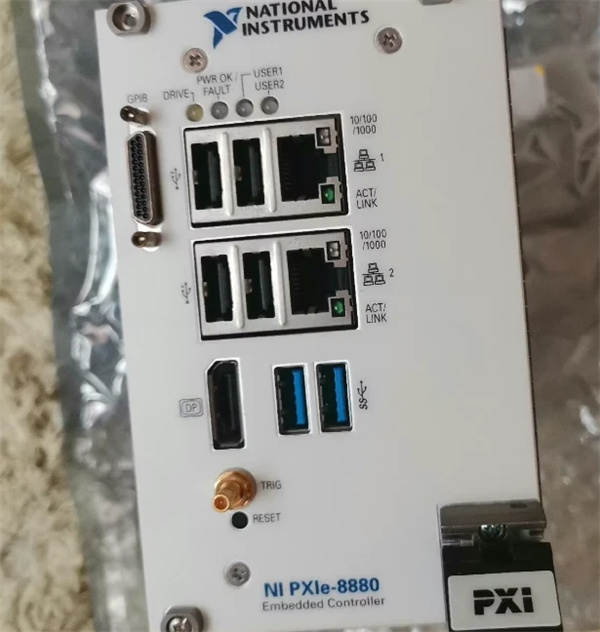

| I/O Ports | 2 USB 3.0 ports, 4 USB 2.0 ports, 2 10/100/1000Base-T (Gigabit) Ethernet ports, DisplayPort, GPIB and SMB trigger |

| PXIe Interface | One x16 and one x8 Gen 3 PCI Express link to PXI chassis backplane, up to 24 GB/s system bandwidth, 8 GB/s slot bandwidth |

| Operating System | Windows (e.g., Windows 7 64-bit), also supports LabVIEW Real-Time |

| Weight | 1.5 kg |

| Operating Temperature Range | 0 °C – 50 °C |

| Storage Temperature Range | -40 °C – 71 °C |

NI PXIe-8880

2. Product Introduction

The NI PXIe-8880 is a high-performance embedded controller designed specifically for PXI Express systems. As part of NI’s advanced product lineup, it brings unparalleled computing power to the automation and test & measurement domains.

With its Intel Xeon E5-2618L v3 8-core processor, the PXIe-8880 can handle processor-intensive tasks with ease. It serves as the brain of a PXI Express system, coordinating data flow, running complex algorithms, and controlling various modules. This controller is optimized for applications such as high-frequency RF testing, modular instrumentation setups, and large-scale data acquisition. Its multiple high-speed I/O ports enable seamless connection with external devices, while the large-capacity SSD ensures quick data storage and retrieval. In an automation system, the PXIe-8880 acts as the central hub, integrating different functions and ensuring smooth operation across the entire system.

3. Core Advantages and Technical Highlights

Exceptional Processing Power: The 8-core Intel Xeon E5-2618L v3 processor, with a base frequency of 2.3 GHz and up to 3.4 GHz in single-core Turbo Boost mode, offers outstanding computational capabilities. It can handle multiple complex tasks simultaneously, such as real-time signal processing in 5G cellular research or semiconductor production test, where high-speed data analysis is crucial.

High Bandwidth Connectivity: The PXIe-8880 features one x16 and one x8 Gen 3 PCI Express link, providing up to 24 GB/s of system bandwidth and 8 GB/s of slot bandwidth. This high bandwidth allows for rapid data transfer between the controller and other PXIe modules, enabling applications like RF record and playback with high data throughput requirements.

Versatile I/O Configuration: Equipped with 2 USB 3.0 ports, 4 USB 2.0 ports, and 2 Gigabit Ethernet ports, the controller offers flexibility in connecting to a wide range of peripherals. The DisplayPort, GPIB, and SMB trigger further expand its connectivity options, making it suitable for diverse applications, from industrial control to scientific research.

Scalable Memory and Storage: With the ability to upgrade from 8 GB to 24 GB of DDR4 RAM and a standard 480 GB SSD, the PXIe-8880 can adapt to the changing needs of different applications. This scalability ensures that the controller can handle large amounts of data and complex software without performance degradation.

4. Typical Application Scenarios

5G Cellular Research: In 5G development, the PXIe-8880 is used to control and analyze high-speed RF signals. Its powerful processing capabilities enable real-time processing of large volumes of data generated by 5G test equipment, such as baseband signal processing and antenna array calibration.

Semiconductor Production Test: During semiconductor manufacturing, this controller manages high-throughput test systems. It coordinates with various test modules to perform rapid and accurate electrical and functional tests on semiconductor devices, ensuring product quality and reliability.

RF Record and Playback: For applications like radar testing or wireless communication system verification, the PXIe-8880 controls the recording and playback of RF signals. Its high bandwidth and processing speed ensure that the signals are captured and reproduced accurately, even at high frequencies.

Automotive Component Testing: In the automotive industry, the PXIe-8880 is utilized to test components such as engines, transmissions, and sensors. It can generate complex test stimuli, acquire sensor data, and analyze the performance of automotive parts under different conditions.

NI PXIe-8880

5. Related Model Recommendations

PXIe-8840: A quad-core PXI Express controller from the same series. It is a more cost-effective option for applications with less demanding processing requirements compared to the PXIe-8880.

PXIe-1095: A high-performance PXIe chassis that pairs well with the PXIe-8880. It provides the necessary mechanical and electrical support, and together they can achieve the high system bandwidth of the PXIe-8880.

NI LabVIEW: A software platform by NI that is highly compatible with the PXIe-8880. It offers graphical programming capabilities, making it easier to develop applications for the controller, especially for data acquisition and control tasks.

PXIe-6571: A digital I/O module that can be integrated with the PXIe-8880 in test and measurement systems. It allows for digital signal input and output, expanding the functionality of the overall system.

PXIe-5663: An RF vector signal analyzer module. When used with the PXIe-8880, it enables high-performance RF testing, such as in wireless communication research and development.

6. Installation, Commissioning and Maintenance Instructions

Installation Preparation: Before installing the PXIe-8880, ensure the PXI Express chassis is powered off and properly grounded. Use anti-static equipment to avoid electrostatic discharge that could damage the controller. Check the chassis compatibility to ensure it supports the PCI Express Gen 3 interface of the PXIe-8880. Align the controller carefully with the chassis slot and gently insert it, then secure it with the appropriate screws.

Commissioning Steps: Power on the chassis and check if the PXIe-8880 is recognized by the system. Install the necessary operating system, such as Windows or LabVIEW Real-Time, along with the relevant drivers provided by NI. Configure the network settings for the Ethernet ports, set up the storage options, and test the I/O ports with simple devices to ensure proper functionality.

Maintenance Suggestions: Regularly update the firmware of the PXIe-8880 to benefit from the latest features and bug fixes. Monitor the temperature of the controller during operation to prevent overheating, especially in high-load applications. If there are issues with data transfer or performance, check the cable connections and the compatibility of the connected peripherals. In case of hardware failure, contact NI’s technical support for guidance on replacing parts.

7. Service and Guarantee Commitment

NI stands behind the quality of the PXIe-8880 with a comprehensive service and guarantee commitment. The product comes with a standard warranty period, during which NI will repair or replace any defective components free of charge. NI’s global technical support team is available to assist customers with installation, configuration, and troubleshooting. They offer prompt response times and in-depth knowledge to ensure that customers can fully utilize the capabilities of the PXIe-8880. Additionally, NI provides regular software updates and firmware upgrades to keep the controller up-to-date with the latest technologies. This commitment reflects NI’s confidence in the product’s quality and its dedication to customer satisfaction, ensuring that customers can rely on the PXIe-8880 for their critical automation and test & measurement applications.