Description

Detailed parameter table

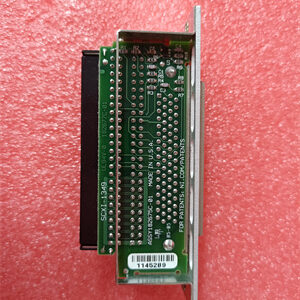

| Parameter name | Parameter value |

| Product model | NI SCXI-1600 |

| Manufacturer | National Instruments (NI) |

| Product category | SCXI-to-DAQ Interface Module |

| Function | Bridges SCXI chassis (e.g., NI SCXI-1000) to NI DAQ devices via PCI/PCIe |

| Compatibility | All NI SCXI chassis (NI SCXI-1000, NI SCXI-1001, NI SCXI-1002) and SCXI modules |

| DAQ Connection | PCI interface (32-bit, 33 MHz) for direct installation in desktop PCs |

| Data Transfer Rate | Up to 1.5 MB/s (sustained) for high-speed signal acquisition |

| Operating Temperature Range | 0 °C to 55 °C |

| Storage Temperature Range | -40 °C to 85 °C |

| Power Requirements | +5 VDC (300 mA) from PCI bus; no external power supply needed |

| Dimensions (W×H×D) | 6.6 in × 2.5 in × 1.0 in (168 mm × 64 mm × 25 mm) |

| Weight | 3.5 oz (100 g) |

| Software Compatibility | NI-DAQmx, LabVIEW, LabWindows/CVI, Measurement Studio |

| Key Functions | Signal routing, chassis synchronization, data transmission between SCXI and DAQ |

| Safety Certifications | UL 60950-1, CSA C22.2 No. 60950-1, IEC 60950-1 |

NI SCXI-1600

Product introduction

The National Instruments SCXI-1600 is a critical interface module that serves as the communication bridge between NI SCXI chassis (such as the NI SCXI-1000) and PCI-based DAQ devices, enabling seamless data transfer from SCXI signal conditioning modules to desktop PCs. As a foundational component of NI’s SCXI ecosystem, it addresses the need for reliable connectivity in measurement systems, ensuring that conditioned signals from modules like the NI SCXI-1141 (isolated analog input) or NI SCXI-1102B (thermocouple input) are accurately transmitted to DAQ hardware for digitization and analysis.

Designed for simplicity and performance, the NI SCXI-1600 installs directly into a PC’s PCI slot, eliminating the need for external cabling between the PC and SCXI chassis. It supports data transfer rates up to 1.5 MB/s, making it suitable for high-throughput applications such as industrial monitoring or lab-based testing. When paired with the NI SCXI-1000 chassis and a compatible DAQ device, the NI SCXI-1600 enables full control of SCXI modules via NI software—users can configure channel settings, trigger measurements, and stream data in real time using LabVIEW or NI-DAQmx. Its compact design and plug-and-play functionality simplify system integration, making it an essential tool for building scalable measurement setups.

Core advantages and technical highlights

High-Speed Data Transfer for Real-Time Measurements:

The NI SCXI-1600 delivers sustained data transfer rates up to 1.5 MB/s, ensuring that high-volume signals from SCXI modules are transmitted to the PC without bottlenecks. This performance is critical for applications like dynamic strain testing or high-speed temperature monitoring, where delayed data can compromise analysis. Unlike slower serial interfaces, the NI SCXI-1600’s PCI bus connection (32-bit, 33 MHz) provides direct access to the PC’s memory, reducing latency and enabling real-time processing of signals from modules like the NI SCXI-1141. For example, in a manufacturing plant monitoring 16 pressure sensors via a NI SCXI-1141, the NI SCXI-1600 ensures pressure spikes are captured and analyzed immediately, triggering alerts for process anomalies.

Seamless Integration with SCXI Ecosystem:

The NI SCXI-1600 is engineered to work flawlessly with all NI SCXI chassis and modules, eliminating compatibility issues that plague third-party interfaces. It automatically detects connected SCXI modules (e.g., NI SCXI-1102B, NI SCXI-1121) when paired with a NI SCXI-1000 chassis, allowing users to configure the entire system via NI-DAQmx or LabVIEW without manual setup. This plug-and-play functionality reduces integration time—what might take hours with generic interfaces can be completed in minutes with the NI SCXI-1600. It also supports chassis synchronization, enabling multiple SCXI systems to operate in tandem for large-scale measurements (e.g., monitoring 64 sensors across four NI SCXI-1000 chassis).

Compact, Cable-Free Design:

By installing directly into a PC’s PCI slot and connecting to the SCXI chassis via a short backplane cable, the NI SCXI-1600 eliminates the clutter of external wiring, reducing the risk of signal interference and cable damage. Its compact form factor (6.6 in × 2.5 in × 1.0 in) saves space in control cabinets or lab setups, while its rugged construction (metal housing) protects internal components from dust and physical stress. This design is particularly beneficial in industrial environments, where cable management is critical for maintaining system reliability. For mobile test carts, the NI SCXI-1600’s cable-free connection to the PC ensures stable operation even when the cart is moved.

Software-Driven Control and Flexibility:

The NI SCXI-1600 integrates fully with NI’s software suite, including LabVIEW, LabWindows/CVI, and NI-DAQmx, enabling users to customize data acquisition workflows. Via software, users can control SCXI module settings (e.g., gain, filter frequency on the NI SCXI-1141), trigger measurements based on external events, and log data to disk—all without hardware reconfiguration. This flexibility allows the NI SCXI-1600 to adapt to changing application needs, such as switching from thermocouple measurements (with NI SCXI-1102B) to strain gage monitoring (with NI SCXI-1121) via software alone. For researchers, this means spending less time on system setup and more time on data analysis.

Typical application scenarios

In automotive engineering labs, the NI SCXI-1600 connects a NI SCXI-1000 chassis (housing NI SCXI-1141 modules) to a PCI-based DAQ system for vehicle component testing. During engine durability tests, the NI SCXI-1141 modules measure 16 temperature and pressure signals from the engine block, with the NI SCXI-1600 transmitting data to the PC at 1.5 MB/s. LabVIEW software processes the data in real time, generating graphs of temperature spikes during acceleration. The NI SCXI-1600’s low latency ensures engineers capture transient events (e.g., turbocharger overheating) that would be missed with slower interfaces, enabling faster design iterations.

In industrial process control, the NI SCXI-1600 integrates a NI SCXI-1000 chassis (with NI SCXI-1102B thermocouple modules) into a factory’s monitoring system. The module transmits temperature data from 8 oven zones to a PC, where it is analyzed to maintain consistent baking temperatures in a food production line. The NI SCXI-1600’s cable-free design reduces wiring in the control cabinet, minimizing the risk of noise interference from nearby motors. Its compatibility with NI-DAQmx allows the system to automatically adjust oven settings when temperatures drift beyond set limits, improving product quality and reducing waste.

In structural health monitoring, the NI SCXI-1600 links a NI SCXI-1000 chassis (with NI SCXI-1121 strain gage modules) to a data logging PC. The system measures strain in a bridge’s steel girders during peak traffic, with the NI SCXI-1600 ensuring 16 channels of data are transmitted without loss. Researchers use LabVIEW to correlate strain patterns with vehicle loads, identifying potential fatigue points. The NI SCXI-1600’s reliable performance in outdoor environments (0 °C to 55 °C) ensures continuous operation, even during temperature fluctuations, providing critical data for bridge maintenance planning.

NI SCXI-1600

Related model recommendations

NI SCXI-1601: A PCIe version of the NI SCXI-1600, offering faster data transfer rates (up to 2.0 MB/s) for high-performance systems. It replaces the NI SCXI-1600 in PCs with PCIe slots, maintaining compatibility with all SCXI chassis and modules.

NI SCXI-1000: The 4-slot SCXI chassis that pairs with the NI SCXI-1600. The interface module connects the chassis to the PC, enabling control of modules like the NI SCXI-1141 and NI SCXI-1102B.

NI PCI-6221: A multifunction DAQ card that works with the NI SCXI-1600 to digitize signals from SCXI modules. The NI SCXI-1600 routes conditioned signals to the NI PCI-6221, which provides 16-bit resolution and 250 kS/s sampling.

NI SCXI-1141: A 16-channel isolated analog input module whose signals are transmitted to the PC via the NI SCXI-1600. The interface module ensures the NI SCXI-1141’s high-voltage isolation and precision are maintained during data transfer.

NI SCXI-1102B: An 8-channel thermocouple module compatible with the NI SCXI-1600. The interface module streams temperature data from the NI SCXI-1102B to the PC, supporting real-time thermal analysis.

NI USB-6210: A portable DAQ device used with the NI SCXI-1600 via a PCI-to-USB adapter (for systems without PCI slots). It extends the NI SCXI-1600’s functionality to laptops and portable test setups.

NI SCXI-1349: A terminal block that complements the NI SCXI-1600 by organizing wiring between SCXI modules (e.g., NI SCXI-1141) and sensors. It works with the interface module to ensure clean signal transmission.

NI LabVIEW: Software used to program and control the NI SCXI-1600 and connected SCXI modules. It provides graphical tools for configuring data acquisition, analyzing signals, and generating reports.

Installation, commissioning and maintenance instructions

Installation preparation

Before installing the NI SCXI-1600, power off the PC and SCXI chassis (e.g., NI SCXI-1000) and wear ESD protection (wrist strap, mat) to prevent electrostatic damage. Verify the PC has an available 32-bit PCI slot (33 MHz) and that the operating system is compatible (Windows 10, Windows 7). Gather tools: a Phillips-head screwdriver (to secure the module to the PC case) and the SCXI chassis backplane cable (included with the NI SCXI-1600). Remove the PC’s side panel, align the NI SCXI-1600 with the PCI slot, and press firmly until seated. Secure the module with the case screw, then connect one end of the backplane cable to the NI SCXI-1600 and the other to the SCXI chassis’ interface port. Power on the SCXI chassis first, then the PC, to ensure proper detection.

Maintenance suggestions

For daily maintenance of the NI SCXI-1600, inspect the PCI connection monthly to ensure the module is fully seated—loose connections cause communication errors. Check the backplane cable for damage (e.g., frayed wires) and replace if necessary, as damaged cables degrade data transfer. Update NI-DAQmx drivers quarterly via NI’s website to ensure compatibility with the latest software (e.g., LabVIEW 2025) and fix potential bugs. Monitor data transfer rates via NI MAX; sustained rates below 1.0 MB/s may indicate a faulty cable or PCI slot, requiring reconnection or slot replacement. When upgrading the PC, remove the NI SCXI-1600 using ESD protection and store it in an anti-static bag. Avoid exposing the module to temperatures outside 0 °C to 55 °C or excessive moisture, as this can damage internal electronics.

Service and guarantee commitment

National Instruments (NI) backs the NI SCXI-1600 with a 2-year standard warranty, covering defects in materials and workmanship—including the PCI interface and data transmission components. If the NI SCXI-1600 fails during the warranty period (e.g., due to connection issues or data transfer errors), NI provides free repair or replacement, with expedited service options for critical systems to minimize downtime. NI’s global technical support team is available 24/7 via email, phone, and chat, offering assistance with installation, driver configuration, and troubleshooting integration with SCXI chassis like the NI SCXI-1000. Additionally, NI provides lifetime access to driver updates, user manuals, and application notes for the NI SCXI-1600, ensuring ongoing compatibility with new hardware and software. This commitment reflects NI’s confidence in the NI SCXI-1600’s reliability as a critical link in SCXI measurement systems.