Description

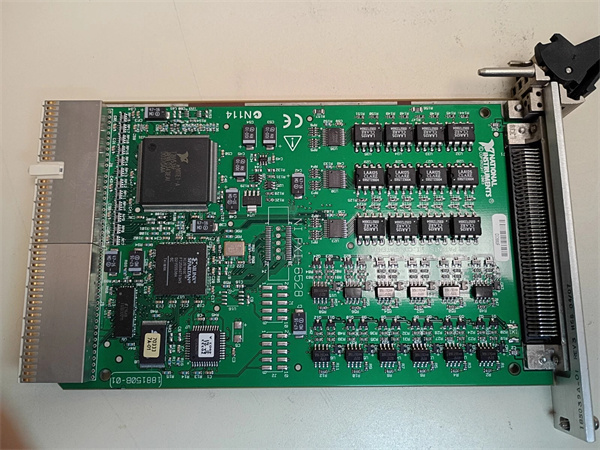

NI PXI – 6521 Product Description

Detailed parameter table

| Parameter name | Parameter value |

| Product model | PXI-6521 |

| Manufacturer | National Instruments (NI) |

| Product category | Digital I/O module |

| Digital I/O channels | 64 bidirectional channels |

| Maximum data transfer rate | Up to 80 MB/s |

| Signal levels | Supports TTL/CMOS (Transistor – Transistor Logic/Complementary Metal – Oxide – Semiconductor) |

| Isolation | None (non – isolated) |

| Triggering modes | Software – triggered, edge – triggered, level – triggered |

| PXI bus interface | 32 – bit/33 MHz PCI – based PXI bus |

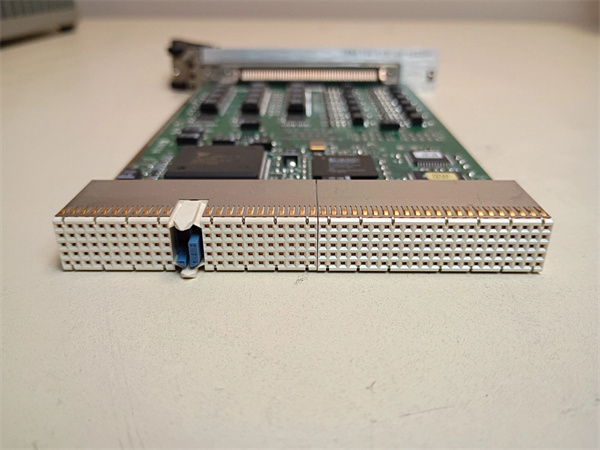

| Dimensions | 10.16 cm (W) x 17.78 cm (D) x 3.81 cm (H) |

| Power consumption | 8 W typical |

| Operating temperature | 0 °C – 55 °C |

| Storage temperature | – 40 °C – 70 °C |

NI PX1-6521

Product introduction

The NI PXI-6521 is a high – performance digital I/O module developed by National Instruments (NI), designed to provide reliable and efficient digital signal handling within PXI – based measurement and automation systems. With 64 bidirectional digital I/O channels, it offers extensive connectivity for interfacing with a wide variety of digital devices and circuits.

Based on the 32 – bit/33 MHz PCI – based PXI bus, the PXI-6521 enables stable data transfer between the module and other components in the PXI system. It supports TTL/CMOS signal levels, ensuring compatibility with numerous digital components commonly used in electronics. The module’s multiple triggering modes, including software – triggered, edge – triggered, and level – triggered, provide users with precise control over data acquisition and signal output. Whether it’s for basic digital control in industrial automation, data logging in research experiments, or simple digital communication tasks, the NI PXI-6521 offers a cost – effective and versatile solution for digital I/O requirements in PXI systems.

Core advantages and technical highlights

Abundant I/O Channels: The NI PXI-6521‘s 64 bidirectional channels provide significant flexibility for digital I/O operations. In large – scale industrial control systems, it can simultaneously connect to multiple sensors, actuators, and other digital devices, enabling comprehensive monitoring and control. For example, in a manufacturing plant’s assembly line, it can manage the digital signals of various robotic arms, conveyor belts, and quality – control sensors, ensuring smooth coordination and efficient production. This high channel count reduces the need for multiple I/O modules, simplifying system design and reducing costs.

Versatile Signal Compatibility: By supporting TTL/CMOS signal levels, the PXI-6521 can interface with a broad range of digital components. TTL/CMOS signals are widely used in digital circuits, making the module suitable for integration into diverse digital systems without the need for additional signal conversion components. This compatibility allows for seamless connection with microcontrollers, digital signal processors, and other digital devices, facilitating the development of complex digital systems.

Flexible Triggering Options: The multiple triggering modes available on the NI PXI-6521 offer users precise control over when digital I/O operations occur. In a data acquisition application, edge – triggering can be used to start collecting data precisely when a specific digital event, such as a rising or falling edge of a signal, occurs. Level – triggering enables data acquisition based on a particular signal level, while software – triggering allows for remote or programmed control. These triggering options enhance the accuracy and efficiency of digital measurement and control systems, enabling users to customize the module’s operation according to their specific application requirements.

Cost – effective and Compact Design: As a PCI – based PXI module, the PXI-6521 offers a cost – effective solution for digital I/O needs. It provides essential features for basic to moderately complex digital applications, making it an attractive choice for budget – conscious users, including educational institutions, small businesses, and hobbyists. Its compact form factor, with dimensions of 10.16 cm (W) x 17.78 cm (D) x 3.81 cm (H), allows for easy integration into PXI chassis, even in space – constrained setups, without sacrificing functionality.

Typical application scenarios

In industrial automation, the NI PXI-6521 plays a vital role in factory – floor control systems. It can be used to control the operation of motors, valves, and other actuators, as well as monitor the status of sensors that detect product presence, position, and quality. For example, in a food packaging plant, it can manage the digital signals of packaging machines, ensuring that products are correctly sealed, labeled, and counted. The module’s reliable performance and multiple triggering modes enable precise control and monitoring of the production process, improving efficiency and reducing errors.

In research laboratories, especially those focused on electronics and digital systems, the PXI-6521 is an essential tool for data acquisition and control. Researchers can use it to interface with experimental circuits and devices, collect digital data, and control the operation of experiments. For instance, in a digital signal processing experiment, it can be used to generate and acquire digital signals, allowing researchers to analyze and optimize signal processing algorithms. The module’s versatility and ease of use make it suitable for a wide range of research applications.

In educational institutions, the NI PXI-6521 is an excellent teaching aid for courses related to digital electronics, control systems, and data acquisition. Students can use it to build hands – on projects, such as simple digital control systems or data logging devices. Its cost – effectiveness and user – friendly design make it accessible for educational purposes, enabling students to gain practical experience in digital I/O operations and system integration.

Related model recommendations

- NI PXI-6537: A more advanced digital I/O module compared to the PXI-6521, offering higher – speed data transfer rates and enhanced timing and triggering capabilities. It is suitable for applications that require more precise control and faster data handling, such as high – speed digital communication or advanced motion control systems. When users need to upgrade their digital I/O system for more demanding tasks, the PXI-6537can provide the necessary performance improvements.

- NI PXIe – 6544: This is a PXI Express – based digital I/O module with a higher maximum data transfer rate of up to 800 MB/s, significantly faster than the PXI-6521. It is ideal for applications that demand high – speed digital data acquisition and control, such as in high – speed imaging or complex industrial automation systems. While it may have a higher cost, it offers superior performance for more data – intensive applications.

- NI PXI-6527: Similar to the PXI-6521but with isolated I/O channels, providing electrical isolation between the module and external devices. It is suitable for applications where electrical isolation is required to prevent electrical interference or protect sensitive equipment, such as in medical electronics or power electronics testing. When users need to ensure electrical safety and signal integrity in their digital I/O systems, the PXI-6527 can be a better choice.

- NI PXI-6536: A digital I/O module with a combination of digital and analog I/O capabilities, offering more versatility compared to the pure digital PXI-6521. It is suitable for applications that require both digital and analog signal handling, such as in mixed – signal measurement and control systems. When users need to build more comprehensive systems that handle different types of signals, the PXI-6536can provide the necessary functionality.

- NI PXI-6509: A lower – cost digital I/O module with fewer channels (32 bidirectional channels) compared to the PXI-6521. It is suitable for applications with less demanding I/O requirements, such as small – scale control systems or simple data acquisition tasks. For users on a tight budget or with basic digital I/O needs, the PXI-6509can be a cost – effective alternative.

Installation, commissioning and maintenance instructions

Installation preparation: Before installing the NI PXI-6521, ensure that the PXI chassis is powered off and properly grounded. Check the compatibility of the chassis with the PXI-6521 in terms of slot type and available power resources. Use appropriate electrostatic – discharge (ESD) protection measures, such as wearing an ESD wrist strap, to prevent damage to the module during handling. When inserting the PXI-6521 into the chassis, align it carefully with the PXI slot and gently push it in until it clicks into place, ensuring a secure connection. Connect all necessary cables, including power cables and any communication cables for configuration, according to the wiring diagrams provided in the product manual.

Maintenance suggestions: Regularly inspect the status indicators on the PXI-6521 to monitor its operation. Clean the ventilation openings of the module and the PXI chassis periodically to prevent dust accumulation, which can affect the heat dissipation and overall performance. Periodically update the firmware of the PXI-6521 as new versions are released to benefit from performance improvements, bug fixes, and enhanced functionality. In case of any abnormal behavior, such as incorrect data readings, signal transmission failures, or module communication errors, first check the cable connections, power supply, and configuration settings. If the problem persists, refer to the troubleshooting guide in the product manual. When replacing any components, use only genuine NI parts to ensure the reliability and performance of the PXI-6521.

Service and guarantee commitment

We have full confidence in the quality and reliability of the NI PXI-6521. The product comes with a comprehensive warranty that covers any manufacturing defects. During the warranty period, if the PXI-6521 fails to perform as specified, we will repair or replace it free of charge. Our dedicated technical support team is available around the clock to assist customers with installation, commissioning, and any technical issues that may arise. We offer a wide range of online resources, including detailed user manuals, software drivers, and application notes, to help users make the most of the PXI-6521. Additionally, we are committed to continuous product improvement and regularly release firmware updates and technical enhancements to ensure that the PXI-6521 remains a leading – edge solution in the digital I/O module market, providing our customers with reliable and high – performing solutions for their measurement and automation needs.

Full 12-month warranty on all components

Dedicated after-sales support

Same-day dispatch on 1000s of parts

All units are fully tested

- 1. Email confirmation

You will get an email confirming that we have received your enquiry. - 2. Dedicated Account Manager

One of our team will be in touch to confirm your part(s) specification and condition. - 3. Your quote

You will receive a comprehensive quote tailored to your specific needs.

Full 12-month warranty

Full 12-month warranty Available for dispatch immediately

Available for dispatch immediately We deliver worldwide

We deliver worldwide Full 12-month warranty on all components

Full 12-month warranty on all components