Description

Product Overview

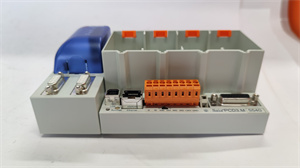

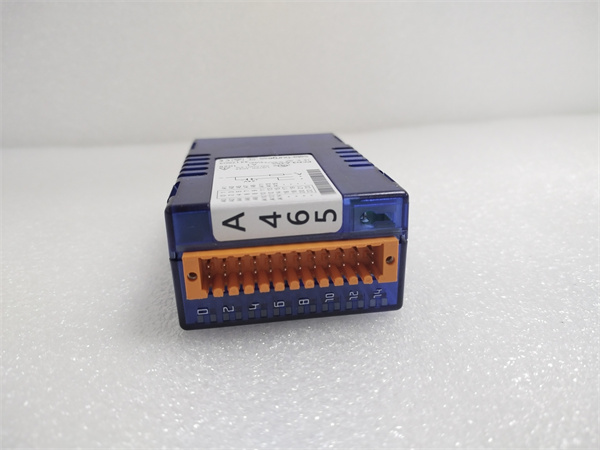

The SAIA PCD3.A465 is likely an advanced programmable control device in SAIA’s product line, representing an evolution in industrial automation technology. SAIA, known for delivering reliable and innovative automation solutions, has presumably engineered the PCD3.A465 to meet the increasingly complex demands of modern industrial applications. This product is designed to act as a central control hub, enabling precise and efficient management of a wide range of industrial processes across diverse sectors, including manufacturing, energy, and building automation.

Built on the foundation of cutting – edge technology and SAIA’s extensive engineering expertise, the PCD3.A465 is expected to offer enhanced processing power, an expanded array of input/output options, and advanced communication capabilities. It is likely equipped to handle intricate control tasks, such as coordinating multiple production lines, optimizing energy consumption in large – scale facilities, and managing complex building systems. Whether deployed in large – scale factories, power plants, or smart buildings, the SAIA PCD3.A465 aims to boost productivity, improve operational efficiency, and ensure the stable and reliable performance of industrial and commercial operations.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | PCD3.A465 |

| Manufacturer | SAIA |

| Product Type | Advanced Programmable Controller |

| Processor Type | [Estimated: High – performance 64 – bit microprocessor for rapid data processing] |

| Memory Capacity | [Estimated: 2 GB for program storage, 1 GB for data storage] |

| Input/Output (I/O) Configuration | [Possible: 32 digital inputs, 32 digital outputs, 8 analog inputs, 4 analog outputs] |

| Digital Input Voltage Range | [Estimated: 24 VDC ±15%] |

| Digital Output Current Rating | [Estimated: 3 A per output] |

| Analog Input Range | [Possible: 0 – 10 V, 4 – 20 mA, ±10 V] |

| Analog Output Range | [Possible: 0 – 10 V, 4 – 20 mA] |

| Communication Protocols | Modbus RTU, Profibus, Ethernet/IP, CANopen, OPC UA, and 5G – enabled communication |

| Input Voltage Range | 100 – 240 VAC, 50/60 Hz or 24 VDC ±20% |

| Power Consumption | [Estimated: 20 W] |

| Operating Temperature Range | -25°C – 65°C |

| Protection Class | [Estimated: IP20 for indoor use, with optional IP65 enclosure for harsh environments] |

| Dimensions | [Estimated: 120mm × 100mm × 70mm] |

| Weight | [Estimated: 0.8 kg] |

SAIA PCD3.A465

Main Features and Advantages

Superior Processing Power

The SAIA PCD3.A465 is likely to feature a high – performance 64 – bit microprocessor, providing significantly faster data processing speeds compared to previous models. This enhanced processing power allows it to execute complex control algorithms in real – time, handle large volumes of input data, and make rapid decisions. In a high – speed manufacturing line, for example, it can quickly analyze sensor data from multiple points and adjust the operation of various machines instantaneously, ensuring seamless production flow and minimizing errors.

Expansive I/O Capabilities

With an estimated configuration of 32 digital inputs, 32 digital outputs, 8 analog inputs, and 4 analog outputs, the PCD3.A465 offers an expansive I/O capacity. This allows it to interface with a vast number of industrial devices, including sensors, actuators, motors, and valves. The increased number of inputs enables comprehensive monitoring of multiple process parameters, while the abundant outputs provide precise control over a wide range of equipment. Whether it’s managing a complex industrial process with numerous variables or integrating multiple subsystems, the PCD3.A465’s I/O capabilities ensure seamless connectivity and efficient operation.

Advanced Communication Protocols

The support for a diverse set of communication protocols, including the addition of OPC UA and 5G – enabled communication, gives the SAIA PCD3.A465 outstanding communication capabilities. OPC UA enables seamless data exchange between different automation systems and software applications, facilitating integration with enterprise – level management systems. The 5G – enabled communication allows for ultra – fast, reliable, and low – latency data transfer, enabling remote monitoring and control from anywhere in the world. It can communicate with a wide range of devices, such as HMIs, cloud – based platforms, and other controllers, creating a connected and intelligent automation ecosystem.

Enhanced Reliability and Durability

Engineered to withstand tough industrial environments, the PCD3.A465 has a wide operating temperature range of -25°C – 65°C and offers an optional IP65 enclosure for protection against dust and water jets in harsh settings. High – quality components and strict manufacturing processes ensure its long – term reliability, reducing the risk of failures and minimizing costly downtime. Its robust design makes it suitable for use in demanding applications, such as outdoor power plants, mining facilities, and industrial plants with high levels of vibration and dust.

User – Friendly and Flexible Programming

The SAIA PCD3.A465 likely supports a variety of programming languages, including Ladder Diagram (LD), Structured Text (ST), Function Block Diagram (FBD), and Sequential Function Chart (SFC). This flexibility caters to programmers with different backgrounds and preferences, making it easy to customize the controller for specific applications. Additionally, it may come with an intuitive programming environment that offers features like drag – and – drop functionality, code debugging tools, and real – time simulation, reducing the development time and effort required to implement control programs.

SAIA PCD3.A465

Application Field

In the manufacturing industry, the SAIA PCD3.A465 can be employed to manage complex production lines. It can control the movement and operation of robotic arms, regulate the speed of conveyor belts, and monitor the quality of products in real – time. For example, in an electronics manufacturing plant, it can ensure the precise assembly of components, adjust the production speed based on demand, and detect any defects immediately, improving overall production efficiency and product quality.

In the energy sector, it plays a crucial role in power generation plants and renewable energy systems. In a thermal power plant, it can optimize the combustion process, manage the operation of turbines and generators, and control the distribution of electricity. In wind farms and solar power plants, it can adjust the orientation of wind turbines and solar panels for maximum energy capture, monitor the performance of energy storage systems, and communicate with the power grid to ensure stable energy supply.

For smart building automation, the PCD3.A465 can integrate and manage various building systems, such as HVAC, lighting, security, and access control. It can optimize energy consumption by adjusting the HVAC settings based on occupancy and weather conditions, control the lighting levels to create a comfortable environment while saving energy, and manage access to different areas of the building for enhanced security.

Related Products

- SAIA PCD2.A465: A previous – generation model with lower processing power, fewer I/O points, and limited communication capabilities compared to the A465. It may be suitable for less complex automation applications or for budget – conscious projects.

- SAIA PCD3.A466: An upgraded variant of the A465, potentially offering additional I/O options, higher memory capacity, or enhanced communication features. It could be designed for extremely complex industrial applications that demand the highest level of performance.

- SAIA PCD3.A465 – A: A customized version optimized for a specific industry, such as the pharmaceutical industry. It might include features like enhanced data logging for regulatory compliance, strict security protocols for protecting sensitive production data, and specialized control algorithms for pharmaceutical manufacturing processes.

- SAIA PCD3.A465 – B: This version could have a different form factor or mounting option, making it more suitable for installation in compact or space – constrained environments, such as small control cabinets in commercial buildings or portable industrial equipment.

- SAIA PCD4.A465: A next – generation model that may feature even more advanced technology, such as artificial intelligence – based control algorithms, improved cybersecurity features, and compatibility with emerging industrial standards.

Installation and Maintenance

Pre – installation preparation: Before installing the SAIA PCD3.A465, carefully read and understand the product installation manual. Ensure that the installation environment meets the specified temperature, humidity, and electrical requirements. Select an appropriate mounting location, whether in a control panel, enclosure, or on a DIN – rail, ensuring proper ventilation and accessibility for future maintenance. Prepare all necessary tools, mounting hardware, and cables. Connect the power cable to a stable power source, either 100 – 240 VAC or 24 VDC within the specified tolerance range. Then, connect the input and output cables to the relevant industrial devices according to the provided wiring diagrams, ensuring all connections are secure, properly insulated, and labeled for easy identification.

Maintenance recommendations: Regularly inspect the PCD3.A465 for any signs of abnormal operation, such as unusual noises, overheating, or error messages on the display (if applicable). Check the tightness of all cable connections periodically to ensure reliable communication and proper functioning of the I/O devices. Clean the exterior of the controller and, if using an enclosure, the interior as well, to remove dust and debris, especially in dusty environments. Update the controller’s firmware regularly to benefit from the latest features, performance improvements, and security patches. In case of a malfunction, refer to the detailed troubleshooting guide in the product manual or contact SAIA’s technical support team for professional assistance. Keep comprehensive records of all maintenance activities, including inspection dates, firmware updates, component replacements, and any issues resolved, for future reference and to ensure proper long – term maintenance of the device.

Product Guarantee

SAIA stands firmly behind the quality of the SAIA PCD3.A465. The product undergoes rigorous quality control procedures during manufacturing to meet and exceed the highest industry standards. SAIA typically offers a [X] – year warranty on this product. During the warranty period, if any quality issues arise due to manufacturing defects, SAIA will provide free repair or replacement services. Additionally, their professional technical support team is available 24/7 to assist customers with installation, operation, and maintenance questions. Whether it’s helping with complex system integration, resolving technical glitches, or providing advice on optimizing performance, the support team ensures that customers can use the PCD3.A465 with confidence, maximizing the value and reliability of their industrial and commercial automation systems.