Description

Product Overview

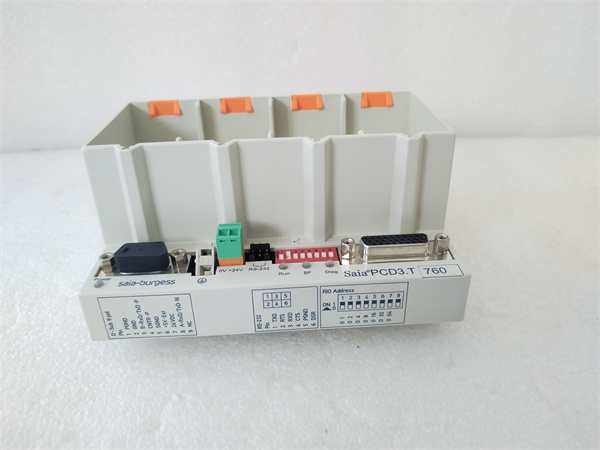

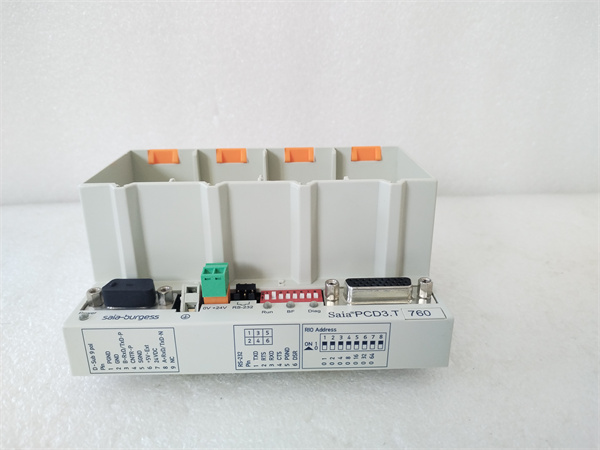

The SAIA PCD3.T760 is likely a specialized programmable control device within SAIA’s diverse product portfolio, engineered to address the unique demands of specific industrial automation scenarios. SAIA, a well – respected name in the automation industry, has presumably designed the PCD3.T760 to offer a blend of performance, reliability, and flexibility. This product may serve as a key control unit in various industrial applications, enabling precise monitoring and regulation of processes across sectors such as manufacturing, energy management, and building automation.

Built on SAIA’s advanced technology and engineering know – how, the PCD3.T760 is expected to feature a capable processing unit, a tailored input/output (I/O) configuration, and robust communication capabilities. It is designed to handle a wide range of control tasks, from managing basic machinery operations to coordinating more complex production sequences. Whether deployed in large – scale industrial plants or smaller – scale commercial facilities, the SAIA PCD3.T760 aims to enhance operational efficiency, improve productivity, and ensure the stable and reliable performance of industrial processes.

Technical Specifications

| Parameter Name | Parameter Value |

| Product Model | PCD3.T760 |

| Manufacturer | SAIA |

| Product Type | Programmable Controller |

| Processor Type | [Estimated: High – performance 32 – bit microprocessor for efficient data processing] |

| Memory Capacity | [Estimated: 1.5 GB for program storage, 768 MB for data storage] |

| Input/Output (I/O) Configuration | [Possible: 32 digital inputs, 32 digital outputs, 8 analog inputs, 4 analog outputs] |

| Digital Input Voltage Range | [Estimated: 24 VDC ±12%] |

| Digital Output Current Rating | [Estimated: 2.5 A per output] |

| Analog Input Range | [Possible: 0 – 10 V, 4 – 20 mA, ±5 V] |

| Analog Output Range | [Possible: 0 – 10 V, 4 – 20 mA] |

| Communication Protocols | Modbus RTU, Profibus, Ethernet/IP, CANopen, and a proprietary SAIA protocol for enhanced compatibility |

| Input Voltage Range | 24 VDC ±18% or 110 – 240 VAC, 50/60 Hz |

| Power Consumption | [Estimated: 18 W] |

| Operating Temperature Range | -20°C – 65°C |

| Protection Class | [Estimated: IP20 for indoor use, optional IP65 for harsher environments] |

| Dimensions | [Estimated: 100mm × 90mm × 70mm] |

| Weight | [Estimated: 0.7 kg] |

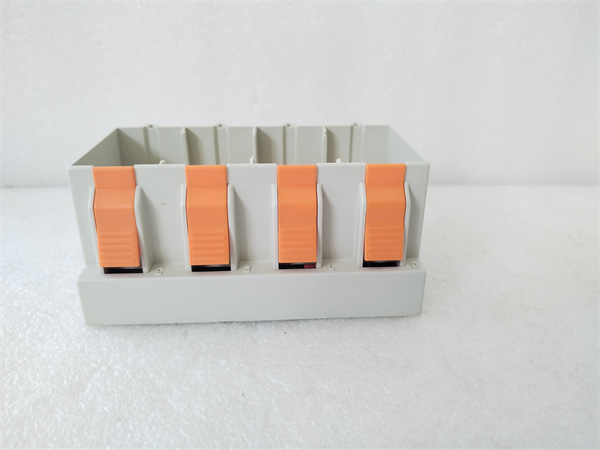

| Expansion Slots | 2 slots for additional I/O modules or communication cards |

SAIA PCD3.T760

Main Features and Advantages

Efficient Processing and Responsive Control

The SAIA PCD3.T760 is likely powered by a high – performance 32 – bit microprocessor, enabling it to execute control programs efficiently and process input data in real – time. This allows for quick responses to changes in industrial processes, ensuring smooth operation of machinery and equipment. In a manufacturing assembly line, for example, it can rapidly analyze sensor data and adjust the operation of conveyors, robotic arms, and other devices, minimizing production delays and improving overall throughput.

Tailored I/O Setup for Versatile Connectivity

With its configuration of 32 digital inputs, 32 digital outputs, 8 analog inputs, and 4 analog outputs, along with expansion slots, the PCD3.T760 offers a versatile I/O system. The digital inputs can monitor the status of various sensors and switches, while the digital outputs control actuators and other devices. The analog I/O enables precise measurement and control of continuous variables, such as temperature, pressure, and flow rate. The ability to expand the I/O capacity through additional modules makes it adaptable to different industrial applications, whether it’s a simple automation task or a more complex system integration project.

Robust Communication Capabilities

Supporting multiple communication protocols, including Modbus RTU, Profibus, Ethernet/IP, CANopen, and a proprietary SAIA protocol, the SAIA PCD3.T760 ensures seamless communication with a wide range of industrial devices. It can easily connect to human – machine interfaces (HMIs), other controllers, sensors, and actuators, enabling real – time data exchange and remote monitoring and control. The proprietary SAIA protocol may offer enhanced compatibility and faster data transfer within SAIA – based systems, facilitating more efficient integration and operation of the overall automation setup.

Reliable and Compact Design

Engineered to withstand the rigors of industrial environments, the PCD3.T760 has a wide operating temperature range of -20°C – 65°C and offers an optional IP65 protection class for harsher settings. High – quality components and strict manufacturing standards contribute to its long – term reliability, reducing the risk of failures and minimizing downtime. Its compact size and lightweight design make it easy to install in control panels or other industrial enclosures, saving space and simplifying the installation process.

User – Friendly Programming and Configuration

The SAIA PCD3.T760 likely supports popular programming languages like Ladder Diagram (LD), Structured Text (ST), and Function Block Diagram (FBD), catering to programmers with different skill levels and preferences. It may come with an intuitive programming environment that provides features such as code autocompletion, debugging tools, and simulation capabilities, making it easier to develop, test, and deploy control programs. Additionally, the device can be configured through a web – based interface or dedicated software, allowing users to customize its settings according to specific application requirements without much hassle.

SAIA PCD3.T760

Application Field

In the manufacturing industry, the SAIA PCD3.T760 can be used to control various production processes. For example, in a metalworking factory, it can manage the operation of CNC machines, control the speed and feed of cutting tools, and monitor the quality of machined parts through sensors. In a food processing plant, it can regulate the temperature and humidity in processing chambers, control the filling and packaging machines, and ensure compliance with safety and quality standards.

In the energy management sector, the PCD3.T760 can play a role in optimizing the operation of renewable energy systems. In a solar power plant, it can control the tracking systems of solar panels to maximize sunlight absorption, manage the energy storage system, and monitor the power output. In a building’s energy management system, it can adjust the heating, ventilation, and air – conditioning (HVAC) systems based on occupancy and weather conditions, reducing energy consumption and costs.

For building automation, the PCD3.T760 can integrate and manage different building systems, such as lighting, access control, and elevator control. It can automatically adjust the lighting levels according to natural light availability and occupancy, manage access to restricted areas, and coordinate the operation of elevators to improve passenger flow and efficiency.

Related Products

- SAIA PCD3.T750: Potentially a more basic version of the T760, with fewer I/O points, lower memory capacity, and limited communication protocol support. It may be suitable for simpler industrial applications or projects with budget constraints.

- SAIA PCD3.T770: An upgraded model with enhanced features, such as more I/O expansion options, higher processing speed, and additional advanced communication interfaces. It could be designed for more complex industrial applications that require greater performance and functionality.

- SAIA PCD3.T760 – A: A variant with customized features, perhaps optimized for a specific industry like the automotive industry. It might include features like enhanced diagnostic capabilities for vehicle production lines, support for automotive – specific communication protocols, and specialized control algorithms for assembly processes.

- SAIA PCD3.T760 – B: This version could have a different physical form factor or mounting option, making it more suitable for installation in compact or space – constrained industrial settings, such as small control cabinets in data centers or on mobile industrial equipment.

- SAIA PCD4.T760: A next – generation model from the same product line, potentially offering advanced features like artificial intelligence – based control, improved cybersecurity features, and compatibility with emerging industrial Internet of Things (IIoT) standards.

Installation and Maintenance

Pre – installation preparation: Before installing the SAIA PCD3.T760, carefully read the product installation manual. Ensure that the installation environment meets the specified temperature, humidity, and electrical requirements. Select an appropriate mounting location, such as a DIN – rail in a control panel or an industrial enclosure, ensuring proper ventilation and easy access for future maintenance. Prepare all necessary tools, mounting hardware, and cables. Connect the power cable to a stable power source, either 24 VDC or 110 – 240 VAC within the specified range. Then, connect the input and output cables to the relevant industrial devices according to the provided wiring diagrams, making sure all connections are secure, properly insulated, and clearly labeled. If planning to use the communication features, configure the network settings and verify the compatibility of the communication protocols with other devices in the system.

Maintenance recommendations: Regularly inspect the PCD3.T760 for any signs of abnormal operation, such as unusual noises, overheating, or error indicators. Check the tightness of all cable connections, including power, I/O, and communication cables, on a regular basis to ensure reliable operation. Clean the exterior of the controller and, if installed in an enclosure, the interior as well, to remove dust and debris, especially in dusty environments. Update the controller’s firmware regularly to benefit from the latest features, performance improvements, and security patches. Utilize the built – in diagnostic features to monitor the health of the device and identify any potential issues early. In case of a malfunction, refer to the troubleshooting guide in the product manual or contact SAIA’s technical support team for assistance. Keep detailed records of all maintenance activities, including inspection dates, firmware updates, component replacements, and any issues resolved, for future reference.

Product Guarantee

SAIA stands firmly behind the quality of the SAIA PCD3.T760. The product undergoes strict quality control procedures during manufacturing to meet the highest industry standards. SAIA typically offers a [X] – year warranty on this product. During the warranty period, if any quality issues arise due to manufacturing defects, SAIA will provide free repair or replacement services. Additionally, their professional technical support team is available to assist customers with installation, operation, and maintenance questions. Whether it’s helping with system integration, resolving technical problems, or providing advice on optimizing performance, the support team ensures that customers can use the PCD3.T760 with confidence, maximizing the value and reliability of their industrial automation systems.