Description

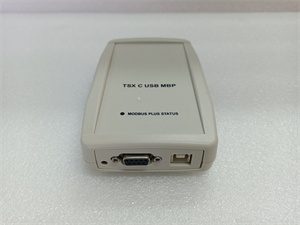

Schneider TSXCUSBMBP

In-depth analysis of Schneider TSXCUSBMBP products

Product overview

The Schneider TSXCUSBMBP is a USB to Modbus Plus adapter for connecting Modicon Quantum series PLCS.It provides a convenient and fast way to connect the USB interface of the computer to Modicon Quantum PLC’s Modbus Plus network for data exchange and device configuration.

Product characteristics

USB interface:Connect the computer through the standard USB interface for easy operation.

Modbus Plus:Supports the Modbus Plus communication protocol commonly used by Modicon Quantum PLC.

Plug and play:Easy to install,no additional drivers required.

High reliability:Industrial grade design to ensure stable operation.

Product parameters(typical values,specific parameters refer to the product data manual)

Interface type:USB Type A

Communication protocol:Modbus Plus

Data transmission rate:high-speed data transmission

Operating temperature:0℃~60℃

Relative humidity:below 95%(no condensation)

Product specification

Installation mode:USB port directly connected

Certification:CE,UL,etc

series

It belongs to the Schneider Electric Modicon Quantum series.

trait

Easy connection:USB interface directly connected

Support Modbus Plus:Strong compatibility

Plug and play:Simple operation

High reliability:Stable operation

effect

Connect the computer to the PLC:Establish a communication connection between the computer and Modicon Quantum PLC.

Data transmission:two-way transmission of data between computer and PLC.

Equipment configuration:PLC configuration and programming through the computer.

use

PLC programming and debugging:Use the programming software on the computer to program and debug the PLC.

Data acquisition:Data is read from the PLC and transferred to the computer for analysis.

Remote monitoring:The operation status of the PLC is monitored remotely through the computer.

Application field

Industrial automation:Used in various industrial automation systems,such as production lines,packaging lines,etc.

Process control:In the process control system,the monitoring and control of process variables are realized.

Data acquisition and analysis:Used to collect and analyze production data.