Description

1. Product Description

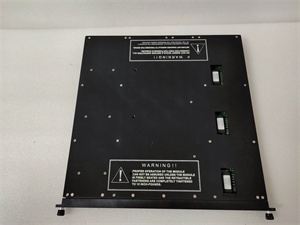

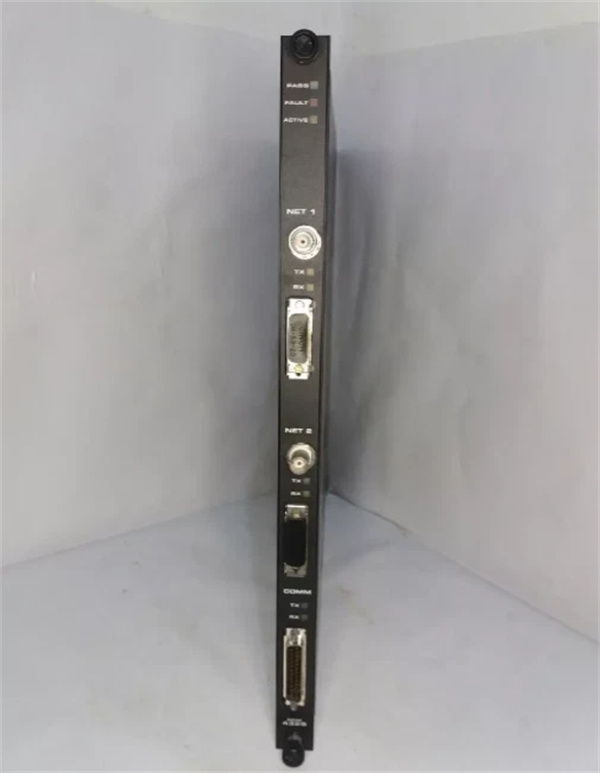

The TRICONEX 4329 is a high-performance network communication module designed to enable secure and reliable data exchange in industrial automation systems, particularly in safety-critical environments. As part of TRICONEX’s Triple Modular Redundancy (TMR) architecture, this module ensures continuous operation by processing data through three independent channels, with a voting mechanism to resolve discrepancies and maintain system integrity.

The TRICONEX 4329 supports Ethernet (802.3) and RS-232 communication protocols, making it ideal for integrating with distributed control systems (DCS), safety instrumented systems (SIS), and emergency shutdown (ESD) systems. Its core function is to bridge the gap between TRICONEX control platforms and external devices, enabling real-time data transmission and control in industries such as oil and gas, chemical processing, and power generation.

Engineered with industrial-grade durability, the TRICONEX 4329 features two BNC Ethernet ports (10 Mbps) and one RS-232 serial port, supporting coaxial cable (RG58) for distances up to 185 meters and fiber-optic communication for long-distance connectivity up to 4 kilometers with repeaters. Its ruggedized design resists electromagnetic interference (EMI), extreme temperatures (-40°C to +70°C), and voltage surges, ensuring stable performance in harsh industrial settings.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | DC 24V ±15%, isolated |

| Communication Interfaces | 2 × BNC Ethernet (10 Mbps), 1 × RS-232 |

| Protocol Support | TRICONEX proprietary protocols, TSAA, Modbus, TCP/IP |

| Max Transmission Distance | 185 meters (coaxial), 4 km (fiber-optic with repeaters) |

| Operating Temperature | -40°C to +70°C |

| Storage Temperature | -50°C to +85°C |

| Humidity Resistance | 5% to 95% non-condensing |

| Redundancy | Triple Modular Redundancy (TMR) |

| Certifications | IEC 61508 SIL 3, CE, UL, IP67 |

| Compatibility | TRICONEX Triplex control systems, Tricon Vx platforms |

TRICONEX 4329

3. Advantages and Features

1. TMR Technology: The TRICONEX 4329 leverages triple modular redundancy to provide fault tolerance, ensuring system continuity even if one channel fails. This design achieves a Mean Time Between Failures (MTBF) exceeding 250,000 hours, significantly reducing unplanned downtime.

2. Multi-Protocol Flexibility: Supports a wide range of communication protocols, including TRICONEX’s proprietary TSAA and standard protocols like Modbus and TCP/IP, enabling seamless integration with diverse industrial devices and systems.

3. Hot-Swappable Design: Technicians can replace the module without powering down the system, cutting maintenance time by up to 60% compared to non-redundant alternatives. This feature is critical for applications requiring continuous operation.

4. Long-Distance Connectivity: Fiber-optic support extends communication up to 4 kilometers, making it suitable for large-scale industrial plants or offshore platforms where physical separation is necessary.

5. Advanced Diagnostics: Real-time health monitoring and self-diagnostic tools detect faults early, enabling proactive maintenance. Alarms and status indicators provide immediate feedback on signal integrity.

4. Application Areas and Use Cases

Industry Applications:

- Oil and Gas: Remote wellhead monitoring, offshore platform ESD systems, and pipeline safety controls.

- Chemical Processing: Distributed reactor control, hazardous material handling, and batch process automation.

- Power Generation: Turbine monitoring, substation automation, and grid stabilization.

Case Study:

In a large liquefied natural gas (LNG) terminal, the TRICONEX 4329 was deployed to connect remote cryogenic pump sensors to the central SIS. The module’s fiber-optic capabilities and TMR technology ensured reliable data transmission across 4 kilometers of harsh coastal terrain, while its diagnostics detected a potential sensor fault before it escalated. This prevented a critical process shutdown and saved over $2 million in potential losses.

In a large liquefied natural gas (LNG) terminal, the TRICONEX 4329 was deployed to connect remote cryogenic pump sensors to the central SIS. The module’s fiber-optic capabilities and TMR technology ensured reliable data transmission across 4 kilometers of harsh coastal terrain, while its diagnostics detected a potential sensor fault before it escalated. This prevented a critical process shutdown and saved over $2 million in potential losses.

5. Competitive Comparison

Against similar industrial communication modules, the TRICONEX 4329 stands out for its combination of TMR redundancy and multi-protocol support. Unlike some alternatives that rely on dual-redundant architectures or limited protocol compatibility, the TRICONEX 4329 offers higher fault tolerance and broader integration capabilities. Its SIL 3 certification also makes it a preferred choice for safety-critical applications compared to modules with lower safety ratings.

TRICONEX 4329

6. Selection Recommendations

- System Compatibility: Verify compatibility with your TRICONEX control platform (e.g., Tricon, Trident) and ensure firmware updates are applied for seamless integration.

- Protocol Requirements: Confirm the module supports the communication protocols needed for your application (e.g., Modbus, TSAA).

- Environmental Conditions: Assess temperature, humidity, and EMI levels at the installation site to match the module’s specifications.

- Safety Compliance: For SIL 3 applications, ensure compliance with IEC 61508 standards and local regulations.

7. Precautions for Use

- ESD Protection: Handle the module with anti-static equipment to prevent damage during installation.

- Fiber Handling: Use ST connectors and follow best practices for fiber-optic cable installation to avoid signal loss.

- Firmware Updates: Regularly update firmware using TRICONEX-approved tools to access new features and security patches.

- Grounding: Ensure proper grounding of the control system to mitigate EMI and voltage surges.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of TRICONEX 4329 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.