Description

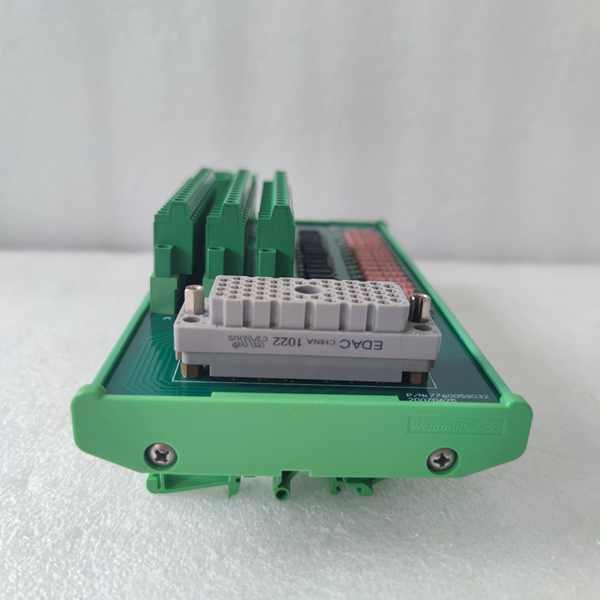

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Input Type | Differential analog input (voltage/current) |

| Channels | 16 channels (isolated per channel) |

| Input Range | Voltage: ±10 V, 0–5 V, 1–5 V; Current: 4–20 mA, 0–20 mA |

| Resolution | 16-bit analog-to-digital conversion |

| Accuracy | ±0.1% of full scale (at 25°C) |

| Common-Mode Rejection | >120 dB (50/60 Hz) |

| Power Supply | 24 V DC (±15%) |

| Operating Temperature | -40°C to +70°C |

| Compatibility | TRICONEX Triplex control systems, supports Tricon EX and Tricon CX platforms |

| Communication | Serial communication with controller via redundant backplane buses |

TRICONEX 9771-210F

3. Advantages and Features

4. Application Areas and Case Studies

5. Competitor Comparison

Compared to similar analog input modules on the market, the TRICONEX 9771-210F offers superior noise rejection and a wider operating temperature range, making it a preferred choice for harsh industrial environments. Its triple-redundant design (as part of the Triplex system) provides an additional layer of fault tolerance, surpassing many single-channel or dual-redundant alternatives. The module also offers faster signal conversion rates and more comprehensive diagnostic capabilities, enhancing system responsiveness and maintainability.

TRICONEX 9771-210F

6. Selection Recommendations

- Compatibility: Ensure the module is compatible with your existing TRICONEX control system platform (e.g., Tricon EX, Tricon CX) and backplane architecture.

- Input Requirements: Verify that the module’s input range and channel count match your application’s signal types (voltage/current) and monitoring needs.

- Environmental Conditions: Assess the operating temperature, humidity, and vibration levels of your installation site to ensure the module’s specifications align with environmental demands.

- Redundancy Needs: If high availability is critical, pair the module with TRICONEX’s redundant power and communication systems for enhanced fault tolerance.

7. Precautions

- Installation: Follow electrostatic discharge (ESD) precautions during handling and installation to prevent component damage.

- Wiring: Use shielded cables for analog inputs to minimize electromagnetic interference, and ensure proper grounding as per industry standards.

- Software Configuration: Validate firmware and software versions to ensure compatibility with the control system, and configure input ranges and scaling parameters correctly to avoid measurement errors.

- Maintenance: Regularly review diagnostic reports to identify potential channel faults and schedule preventive maintenance during planned outages to avoid unplanned downtime.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.