Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Analog Input Module (AI) |

| Channels | 16 isolated channels |

| Input Range | 4-20 mA, 0-5 V, 0-10 V, ±10 V |

| Resolution | 16-bit |

| Accuracy | ±0.1% of full scale |

| Power Supply | 24 V DC (±10%) |

| Isolation | Galvanic isolation (500 V rms) |

| Temperature Range | -40°C to +70°C (operating) |

| Communication Interface | TriBus (proprietary high-speed bus) |

| Redundancy Support | Triplicated hardware (TMR architecture) |

| Compliance | IEC 61508 (SIL 3), NEC Class I Div 2 |

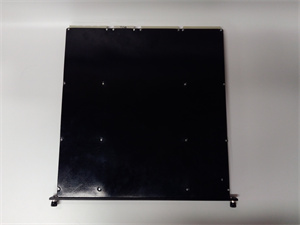

TRICONEX 3720

3. Advantages and Features

4. Application Areas and Case Studies

- Oil and Gas: Monitoring pressure, temperature, and flow rates in upstream and downstream facilities.

- Power Generation: Controlling steam turbine parameters and boiler efficiency in thermal power plants.

- Chemical Processing: Ensuring safe reaction conditions in petrochemical reactors.

5. Competitive Comparison

Compared to similar analog input modules on the market, the TRICONEX 3720 distinguishes itself through its unique combination of triplicated redundancy, wide input range flexibility, and SIL 3 certification. While many alternatives offer basic isolation and signal conversion, few match its ability to maintain full functionality during single-channel faults or operate reliably in extreme temperatures. Its seamless integration with TRICONEX’s broader control ecosystem also simplifies system design, reducing compatibility issues often encountered with multi-vendor setups.

TRICONEX 3720

6. Selection Recommendations

- System Compatibility: Ensure your control system supports TriBus communication and TMR architecture.

- Signal Requirements: Verify that the module’s input range matches your field instruments (e.g., 4-20 mA for transmitters).

- Environmental Needs: If deploying in harsh conditions, confirm the temperature, vibration, and corrosion resistance meet site specifications.

- Scalability: Evaluate whether the 16-channel configuration aligns with current and future monitoring needs to avoid over-provisioning or under-capacity.

7. Precautions

- Installation: Always power down the system before installing or replacing the module, and use anti-static wrist straps to prevent ESD damage.

- Wiring: Follow shielded cable practices to minimize electromagnetic interference (EMI), and ensure proper grounding for isolated channels.

- Calibration: Perform periodic calibration checks using certified test equipment to maintain accuracy, especially after hardware changes or extreme temperature cycles.

- Firmware Management: Keep the module’s firmware updated to the latest version provided by the manufacturer to access the latest diagnostic features and safety patches.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.