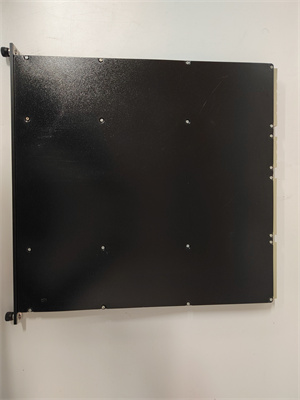

Description

Triconex 3721

Description of the Triconex 3721 analog input module

Product overview

The Triconex 3721 Analog input module is an integral part of the Triconex Safety Instrumentation System (SIS), which converts analog signals from field equipment (such as temperature, pressure, flow, etc.) into digital signals that the Triconex system can handle. The module has high precision and high reliability, and is widely used in the safety control system of petrochemical, electric power, metallurgy and other industries.

Product characteristics

High precision: provides high precision analog signal acquisition to ensure the accuracy of system control.

High reliability: Redundant design ensures stable operation of the system under extreme conditions.

Multi-channel input: A single module can provide multiple analog input channels to improve system integration.

Isolated input: Input channels are isolated from each other to improve system security.

IEC 61508 compliance: Meets SIL3 functional safety requirements for applications with high safety levels.

Product parameters and specifications

For details, see the Triconex official technical documentation. Generally include:

Number of input channels :4, 8 or 16

Input signal type :4-20mA,0-10V, etc

Accuracy :0.1%FS or higher

Isolation voltage :1500Vrms

Operating temperature: Wide range of operating temperature

Diagnostic function: self-diagnosis, module status monitoring, etc

Product series

The Triconex 3721 is part of the Triconex Safety Instrumentation System and is a model in its family of I/O modules.

Product function and use

Process variable measurement: Measurement of process variables, such as temperature, pressure, flow, etc.

Condition monitoring: monitoring the state of the equipment, such as motor current, vibration, etc.

Process control: Converts analog signals to digital signals to provide input to the process control system.

Application field

Petrochemical: Process control and condition monitoring in petrochemical production processes.

Electricity: Process control and condition monitoring of power plants and substations.

Metallurgy: Process control and condition monitoring of metallurgical production processes.

Pharmaceutical: Process control and condition monitoring of pharmaceutical manufacturing processes.