Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | DC 115V ±15%, isolated |

| Input Voltage Range | 95V to 130V DC |

| Current Consumption | ≤200mA at 115V DC |

| Input Channels | 16 channels (single-ended or differential) |

| Signal Type | Digital input (contact closure or voltage) |

| Response Time | ≤10ms (de-bounce filter configurable) |

| Communication | Proprietary TRICONEX bus (via chassis backplane) |

| Operating Temperature | -40°C to +75°C |

| Storage Temperature | -50°C to +85°C |

| Certifications | CE, UL, IEC 61508 (SIL 3 capable), IP65 for environmental protection |

| Compatibility | TRICONEX Triplex control systems, Tricon Vx platforms |

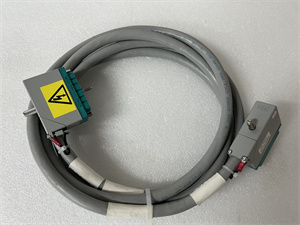

TRICONEX 4000093-110N

3. Advantages and Features

4. Application Areas and Use Cases

- Oil and Gas: Monitoring high-voltage sensors in offshore platforms, wellhead control systems, and pipeline safety valves.

- Chemical Processing: Emergency shutdown (ESD) systems for hazardous material handling and reactor safety interlocks.

- Power Generation: Turbine protection systems, generator breaker control, and substation automation.

In a large petrochemical plant, the TRICONEX 4000093-110N was deployed to monitor 115V DC signals from pressure sensors in a distillation column. The module’s TMR technology detected a gradual voltage drop in one channel due to a failing sensor, triggering an early warning before a critical process shutdown. This allowed maintenance teams to replace the sensor during a planned outage, avoiding an estimated $1.2 million in production losses.

5. Competitive Comparison

Compared to standard digital input modules, the TRICONEX 4000093-110N stands out for its combination of high voltage compatibility and SIL 3 safety certification. While many competing modules support only 24V inputs or lack redundancy, the TRICONEX 4000093-110N offers both high voltage resilience and triple modular redundancy, making it a preferred choice for safety-critical applications. Its plug-and-play compatibility with TRICONEX systems also reduces integration complexity compared to alternatives requiring extensive firmware modifications.

TRICONEX 4000093-110N

6. Selection Recommendations

- Voltage Requirements: Verify that your application requires 115V DC inputs to avoid unnecessary costs.

- System Compatibility: Ensure the module aligns with your TRICONEX control platform (e.g., Tricon, Trident) and firmware versions.

- Safety Compliance: For SIL 3 applications, confirm compliance with IEC 61508 standards and local regulations.

- Environmental Conditions: Assess temperature, humidity, and EMI levels at the installation site to match the module’s specifications.

7. Precautions for Use

- ESD Protection: Handle the module with anti-static equipment to prevent damage during installation.

- Grounding: Ensure proper system grounding to mitigate EMI and voltage surges.

- Firmware Updates: Regularly update firmware using TRICONEX-approved tools to access new features and security patches.

- Signal Wiring: Use shielded cables for high-voltage inputs to minimize interference.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.