Description

1. Product Description

2. Product Parameters

| Parameter | Specification |

|---|---|

| Power Supply | DC 16–32V ±15%, isolated |

| Communication Interface | Fiber-optic (ST connectors), 375 Kbps |

| Max Transmission Distance | 12 km (single-mode fiber) |

| Operating Temperature | -40°C to +75°C |

| Storage Temperature | -50°C to +85°C |

| Humidity Resistance | 5% to 95% non-condensing |

| Redundancy | Triple Modular Redundancy (TMR) |

| Certifications | IEC 61508 SIL 3, IEC 62443-4 PLe, CE, UL |

| Compatibility | TRICONEX Triplex control systems, Tricon Vx platforms |

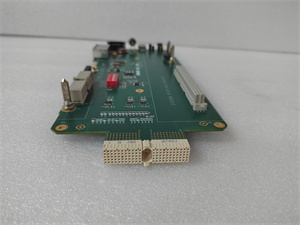

TRICONEX 4211

3. Advantages and Features

4. Application Areas and Use Cases

- Oil and Gas: Remote wellhead monitoring, offshore platform ESD systems, and pipeline safety controls.

- Chemical Processing: Distributed reactor control, hazardous material handling, and batch process automation.

- Power Generation: Turbine monitoring, substation automation, and grid stabilization.

In a large liquefied natural gas (LNG) terminal, the TRICONEX 4211 was deployed to connect remote cryogenic pump sensors to the central SIS. The module’s fiber-optic capabilities and TMR technology ensured reliable data transmission across 10 km of harsh coastal terrain, while its diagnostics detected a potential sensor fault before it escalated. This prevented a critical process shutdown and saved over $2 million in potential losses.

5. Competitive Comparison

Against similar industrial expansion modules, the TRICONEX 4211 stands out for its combination of long-distance fiber-optic support and SIL 3 safety certification. Unlike some alternatives that rely on copper-based communication (limited to 1 km), the TRICONEX 4211’s fiber-optic design offers immunity to EMI and longer reach. Additionally, its TMR architecture provides higher fault tolerance than dual-redundant systems, making it a preferred choice for safety-critical applications.

TRICONEX 4211

6. Selection Recommendations

- System Compatibility: Verify compatibility with your TRICONEX control platform (e.g., Tricon, Trident) and ensure firmware updates are applied for seamless integration.

- Environmental Needs: Assess temperature, humidity, and EMI levels at the installation site to confirm the module’s specifications align with requirements.

- Safety Requirements: For SIL 3 applications, ensure the module’s certification meets industry standards (e.g., IEC 61508).

- Cost Efficiency: Factor in long-term savings from reduced downtime and maintenance enabled by hot-swappable design and TMR reliability.

7. Precautions for Use

- ESD Protection: Handle the module with anti-static equipment to prevent damage during installation.

- Fiber Handling: Use ST connectors and follow best practices for fiber-optic cable installation to avoid signal loss.

- Firmware Updates: Regularly update firmware using TRICONEX-approved tools to access new features and security patches.

- Grounding: Ensure proper grounding of the control system to mitigate EMI and voltage surges.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.