Description

1. Product Description

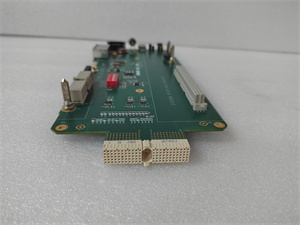

The TRICONEX 8112 is a high-density Remote Expansion Chassis engineered for safety-critical industrial automation systems, delivering exceptional scalability and reliability in harsh operational environments. As a core component of TRICONEX’s Triple Modular Redundancy (TMR) architecture, the TRICONEX 8112 enables seamless extension of I/O capabilities for control systems, supporting industries such as oil & gas, chemical processing, and power generation where uninterrupted operation is non-negotiable.

The primary function of the TRICONEX 8112 is to expand the input/output (I/O) capacity of control systems by housing up to 16 I/O modules and 32-point termination panels, facilitating connection to field devices like sensors, valves, and actuators. Its triplicated communication buses (RS-485 and Ethernet/IP) ensure fault-tolerant data transfer, while the ruggedized design withstands extreme temperatures and vibrations. The chassis supports hot-swappable modules, allowing maintenance or replacement without system shutdown, and integrates seamlessly with TRICONEX controllers (e.g., Tricon CX, EX) to enhance system flexibility and availability.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | Remote Expansion Chassis for safety-critical systems |

| I/O Capacity | Up to 16 I/O modules (supports analog, digital, and specialized modules) |

| Redundancy | Triple Modular Redundancy (TMR) with 2-out-of-3 voting logic |

| Communication Protocols | RS-485 (375 kbps), Ethernet/IP (2 Mbps) |

| Input Voltage | 24V DC (±10%) |

| Power Consumption | < 50 W (maximum under full load) |

| Operating Temperature | -40°C to +70°C (storage: -45°C to +85°C) |

| Humidity | 5%–95% non-condensing |

| SIL Certification | SIL-3 (IEC 61508), suitable for safety-critical applications |

| Compatibility | TRICONEX Tricon CX, EX, and legacy systems; integrates with SCADA and DCS |

| Physical Dimensions | 48.3 cm (W) × 57.8 cm (H) × 45.1 cm (D) (19″ × 22.75″ × 17.75″) |

| Weight | 24.5 kg (54.0 lbs) (empty chassis) |

TRICONEX 8112

3. Advantages and Characteristics

- Triple Modular Redundancy (TMR): The TRICONEX 8112 leverages TMR architecture to provide fault tolerance, with three independent communication paths that vote on data integrity. This design achieves a mean time between failures (MTBF) exceeding 500,000 hours, reducing the risk of system downtime by up to 90% compared to non-redundant chassis solutions.

- High-Density Scalability: Supports up to 16 I/O modules in a single chassis, enabling compact integration of diverse signal types (analog, digital, thermocouple, RTD) without compromising performance. This density reduces rack space requirements by 30% in large-scale control systems.

- Hot-Swap Capability: Faulty modules can be replaced while the system is operational, minimizing maintenance downtime. Technicians can complete module replacement in under 20 minutes, ensuring continuous monitoring and control in critical applications.

- Rugged Environmental Performance: Designed to operate in extreme conditions, the chassis withstands -40°C to +70°C temperatures and high vibration (5g), making it suitable for offshore platforms, refineries, and heavy industrial sites.

- SIL-3 Safety Compliance: Certified to the highest safety integrity level, the TRICONEX 8112 is ideal for safety instrumented systems (SIS), emergency shutdown (ESD) systems, and turbine protection applications where compliance with IEC 61508 is critical.

4. Application Areas and Application Cases

-

Industry Applications:

- Oil & Gas: Expands I/O capacity for monitoring wellhead pressures, pipeline flow rates, and LNG storage tank temperatures in offshore and onshore facilities.

- Chemical Processing: Supports safety interlocks, reactor temperature control, and distillation column monitoring in batch and continuous process systems.

- Power Generation: Facilitates turbine vibration analysis, boiler pressure regulation, and generator protective relay integration in thermal and nuclear power plants.

- Manufacturing: Enables automation of conveyor systems, machine safety interlocks, and quality control sensors in high-speed production lines.

-

Case Study:

A major petrochemical plant in the Middle East deployed the TRICONEX 8112 to expand its SIS, connecting over 200 field devices across three production units. The chassis’s TMR architecture and hot-swappable design allowed the system to maintain full functionality when a communication module failed during peak operation. Technicians replaced the faulty module without interrupting the process, preventing an estimated $500,000 loss in production downtime.

5. Competitive Comparison

Compared to similar expansion chassis solutions, the TRICONEX 8112 stands out for its SIL-3 certification, TMR redundancy, and high-density I/O support. While some alternatives offer basic expansion capabilities, few match its ability to handle safety-critical applications with triplicated communication buses and wide environmental tolerance. Its seamless integration with TRICONEX’s control ecosystem reduces configuration complexity, and the hot-swappable design minimizes maintenance effort, making it a preferred choice for industries prioritizing reliability and scalability.

TRICONEX 8112

6. Selection Recommendations

- System Compatibility: Verify that the TRICONEX 8112 aligns with your TRICONEX controller model (e.g., Tricon CX, EX) and backplane specifications to ensure seamless communication and power supply compatibility.

- I/O Requirements: Assess the number and type of I/O modules needed (e.g., analog input, digital output) to avoid underutilization or overload, ensuring the chassis supports your application’s signal processing needs.

- Environmental Conditions: If installing in harsh environments, confirm the chassis’s temperature, humidity, and vibration ratings match site conditions, especially for offshore or high-temperature industrial settings.

- Redundancy Strategy: For critical applications, pair the TRICONEX 8112 with redundant power supplies and communication networks to maximize fault tolerance and system availability.

7. Precautions

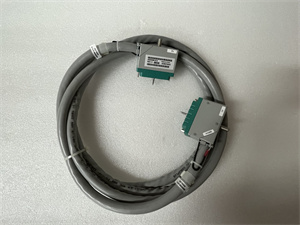

- Installation: Power down the control system and use anti-static wrist straps during installation to prevent electrostatic discharge (ESD) damage. Securely fasten cables and ensure proper grounding to minimize electromagnetic interference (EMI).

- Configuration: Use TRICONEX-approved software tools (e.g., Tristation 1131) to configure module addresses, communication protocols, and redundancy settings, ensuring alignment with safety loop requirements.

- Maintenance: Regularly monitor the chassis’s diagnostic status via the control system interface to detect module faults or communication anomalies. Schedule firmware updates to incorporate the latest safety patches and performance optimizations.

- Troubleshooting: In the event of a module failure, replace it during a planned maintenance window or while the system is in hot-standby mode. Validate system functionality after replacement to ensure all I/O channels operate correctly.

Shanxi Xinyeda International Trade Co., Ltd. is your reliable partner. We provide the sales and technical support of TRICONEX 8112 and other automation spare parts. Please visit our website www.xydcontrol.com or contact us, and we will be happy to serve you.