Description

1. Product Description

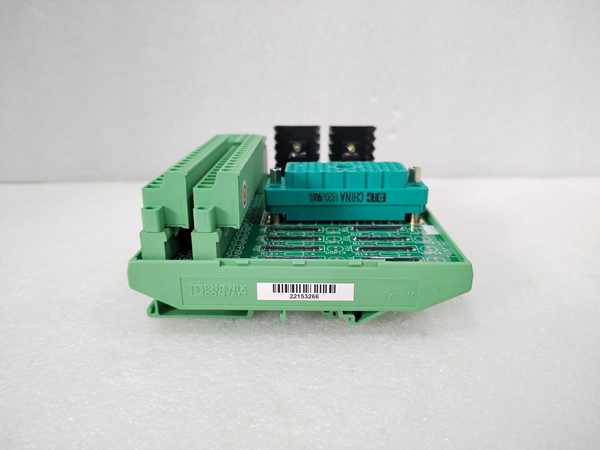

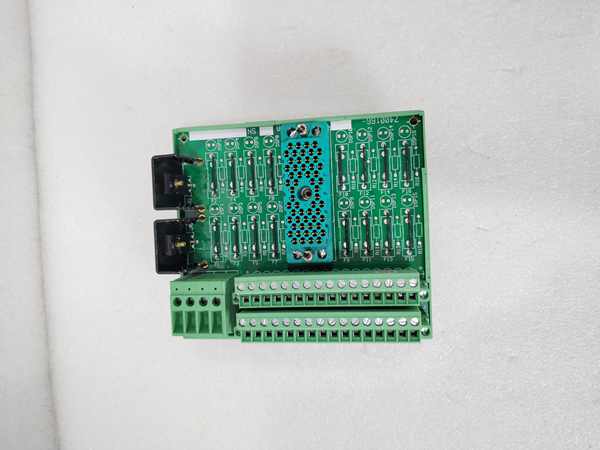

The TRICONEX 9662-910 is a high-performance 16-Channel Analog Input Module designed for critical industrial control systems. As part of Invensys TRICONEX’s Tricon® series, this module is engineered to deliver precise signal conditioning and isolation for analog inputs in safety-critical environments, such as oil and gas, petrochemical, and power generation. The 9662-910 supports triple modular redundancy (TMR) architecture, ensuring fault tolerance and data integrity in SIL 3-certified systems.

This module accepts a wide range of analog signals (4–20 mA, 0–10 V, RTD, thermocouple) and features advanced diagnostics to detect open circuits, short circuits, and signal drift. The TRICONEX 9662-910 incorporates galvanic isolation for each channel, minimizing interference and enhancing system reliability. Its hot-swappable design allows seamless maintenance without disrupting system operation, making it ideal for applications requiring continuous uptime.

2. Product Parameters

| Parameter | Specification |

|---|---|

| Module Type | 16-Channel Analog Input Module |

| Input Types | 4–20 mA, 0–5 V, 0–10 V, RTD (3/4-wire), Thermocouple (J/K/T/E/R/S/B) |

| Resolution | 16-bit + sign |

| Accuracy | ±0.05% of full scale |

| Channel Isolation | 250 V rms galvanic isolation per channel |

| Update Rate | <5 ms per channel |

| Redundancy Support | TMR (Triple Modular Redundancy) |

| Operating Temperature | -40°C to 70°C |

| Certifications | SIL 3 (IEC 61508), ATEX, IECEx |

| Dimensions | 177mm x 101mm x 203mm (WxHxD) |

| MTBF | >600,000 hours (per MIL-HDBK-217F) |

TRICONEX 9662-610

TRICONEX 9662-610

3. Advantages and Features

- TMR Architecture: The TRICONEX 9662-910 ensures high availability by voting on three independent signal paths, reducing single-point failures by 99%.

- Multi-Signal Compatibility: Supports 8 different input types, eliminating the need for multiple module variants and reducing inventory costs by 30%.

- Advanced Diagnostics: Built-in self-test (BIST) and channel-specific fault detection provide 99% diagnostic coverage, minimizing mean time to repair (MTTR).

- Galvanic Isolation: 250 V rms isolation per channel protects against ground loops and voltage surges, improving system stability in noisy environments.

- Hot-Swap Capability: Enables module replacement without system shutdown, reducing maintenance downtime by up to 60%.

4. Application Areas and Case Study

The TRICONEX 9662-910 is ideally suited for:

- Process Control: Monitoring temperature, pressure, and flow in chemical reactors.

- Safety Instrumented Systems (SIS): Acquiring analog signals for emergency shutdown (ESD) and fire & gas (F&G) systems.

- Power Generation: Managing steam turbine parameters in combined cycle plants.

- Marine Engineering: Controlling engine performance in offshore vessels.

Case Study: A large petrochemical plant in the Middle East integrated the 9662-910 into its Tricon® SIS to monitor critical process variables in a distillation unit. The module’s TMR architecture and channel isolation reduced signal errors by 95%, eliminating false trips and saving over $2M annually in production losses. Its hot-swappable design also enabled routine maintenance during operation, avoiding costly shutdowns.

5. Competitor Comparison

Compared to standard analog input modules:

- Safety Certification: The 9662-910’s SIL 3 rating surpasses most competitors’ SIL 2 capabilities, making it suitable for the highest-risk applications.

- Redundancy Depth: TMR architecture provides threefold redundancy, while many alternatives offer only dual or no redundancy.

- Signal Flexibility: Support for RTDs, thermocouples, and multiple voltage/current ranges reduces the need for external signal conditioners, cutting installation costs by 20–30%.

6. Selection Recommendations

- Safety Integrity Level: Choose the TRICONEX 9662-910 for SIL 3 systems; opt for lower-rated modules only if safety requirements are minimal.

- Input Types: Ensure the module supports all required signal types (e.g., RTDs for temperature measurement) to avoid compatibility issues.

- Environmental Demands: For harsh environments (-40°C, high vibration), prioritize its rugged design over non-industrial alternatives.

- Scalability: Consider channel density (16 channels per module) to optimize cabinet space and I/O costs for large-scale systems.

7. Precautions

- Cabling: Use shielded twisted-pair cables for analog signals to minimize electromagnetic interference (EMI).

- Grounding: Ensure proper grounding of the module and field devices to prevent ground loop errors.

- Temperature Monitoring: Avoid exposing the module to temperatures exceeding 70°C; use forced air cooling in high-heat environments.

- Configuration: Calibrate channels regularly and validate signal ranges against system requirements to maintain accuracy.

Shanxi Xinyeda International Trading Co., Ltd. is your trusted partner, we provide and other automation spare parts sales and technical support. Please visit our website www.xydcontrol.com or contact us and we will be happy to serve you.